Nearly-zero inner leakage fluoroplastic magnetic drive pump

A technology of internal leakage and magnetic pump, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve problems such as no working efficiency of magnetic pumps, reduced pump working efficiency, and increased axial clearance , to increase operational safety, improve work efficiency, and reduce frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

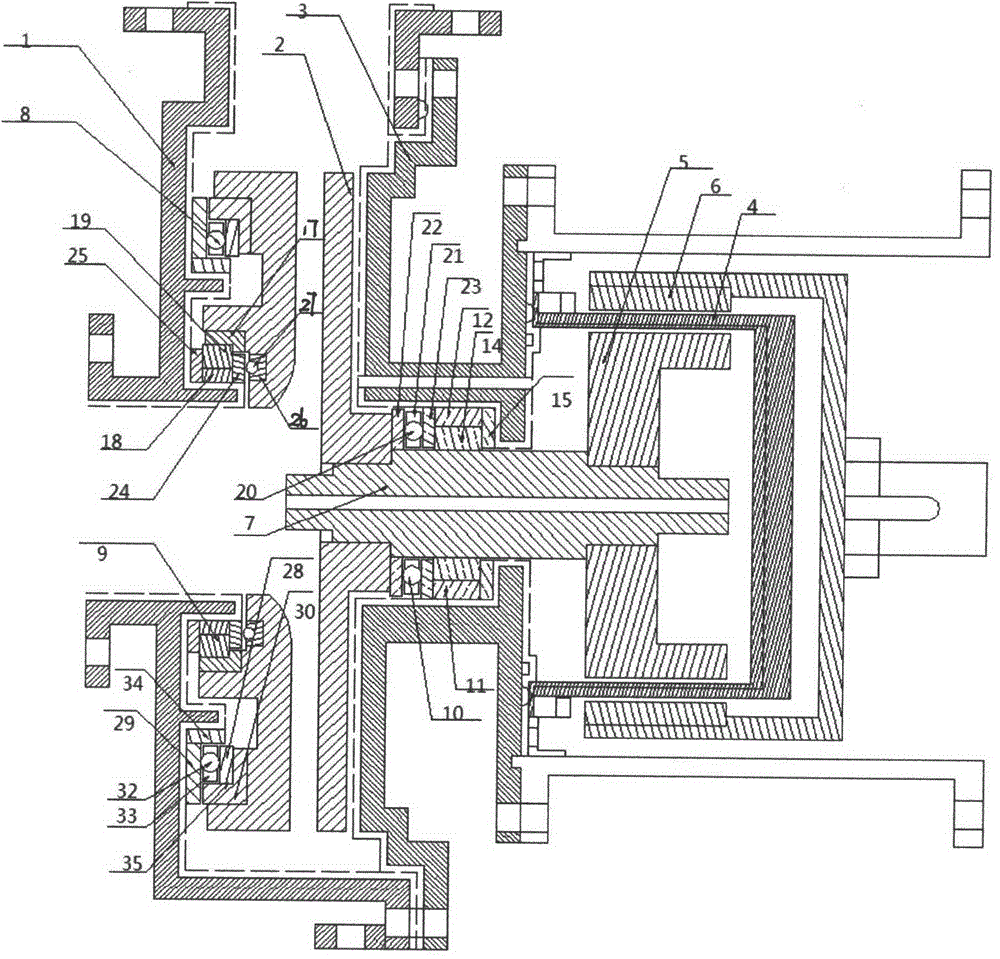

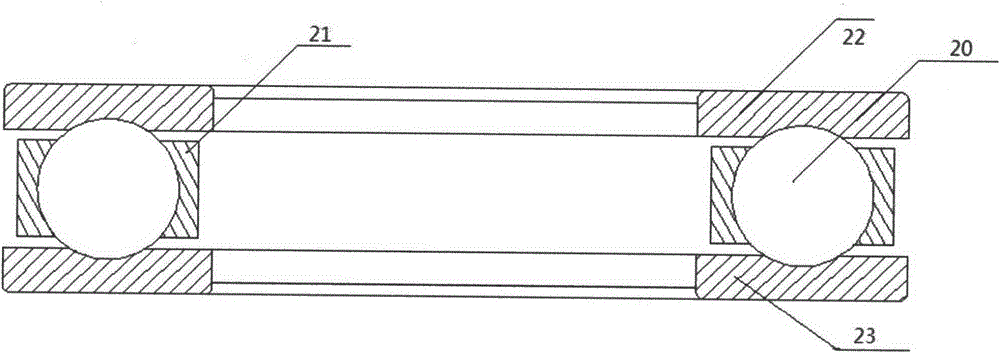

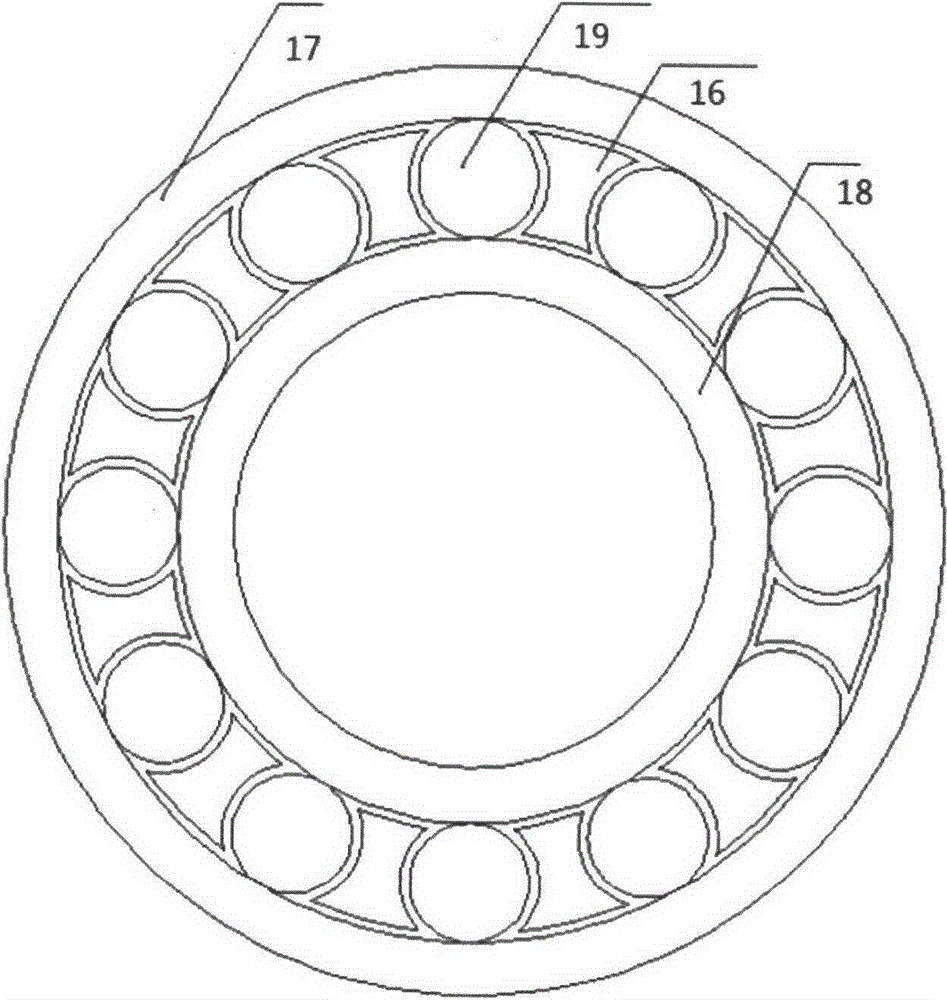

[0022] Embodiment: A fluoroplastic magnetic pump with near-zero internal leakage, including a pump shaft 7, an impeller 2, an inner magnetic rotor 5, an outer magnetic rotor 6, an isolation sleeve 4, an inner worm wall 3, an outer worm wall 1, a second A radial roller bearing 9, a second radial roller bearing 11, a seal ring 8 and an axial ball bearing 10, the inner magnetic rotor 5 is fixedly installed on the shaft end of the pump shaft 7, and the outer magnetic rotor 6 is installed on the shaft end of the motor, A spacer 4 is arranged between the inner magnetic rotor 5 and the outer magnetic rotor 6, and the material of the spacer 4 is one of zirconia or polytetrafluoroethylene composite materials, and the spacer 4 is sealed and fixed with the outer shell of the inner worm wall 3 Connection, the outer volute wall 1 and the inner volute wall 3 are tightly connected, and the outer volute wall 1, the inner volute wall 3 and the isolation sleeve 4 are closed to form a pump chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com