Eccentric shaft assembly for recreational vehicle (RV) reducer

A technology of eccentric shaft and reducer, applied in the field of eccentric shaft, can solve the problems of high processing cost, poor economic applicability, difficulty in ensuring the eccentric accuracy of the crank shaft, etc., and achieves the effect of convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

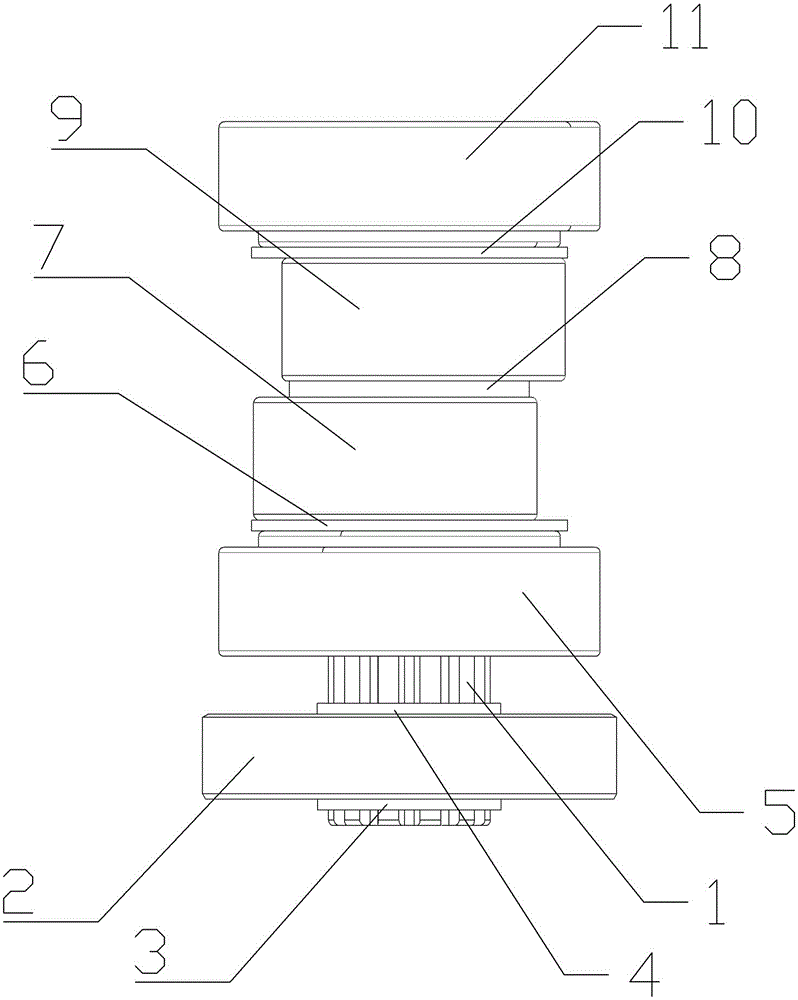

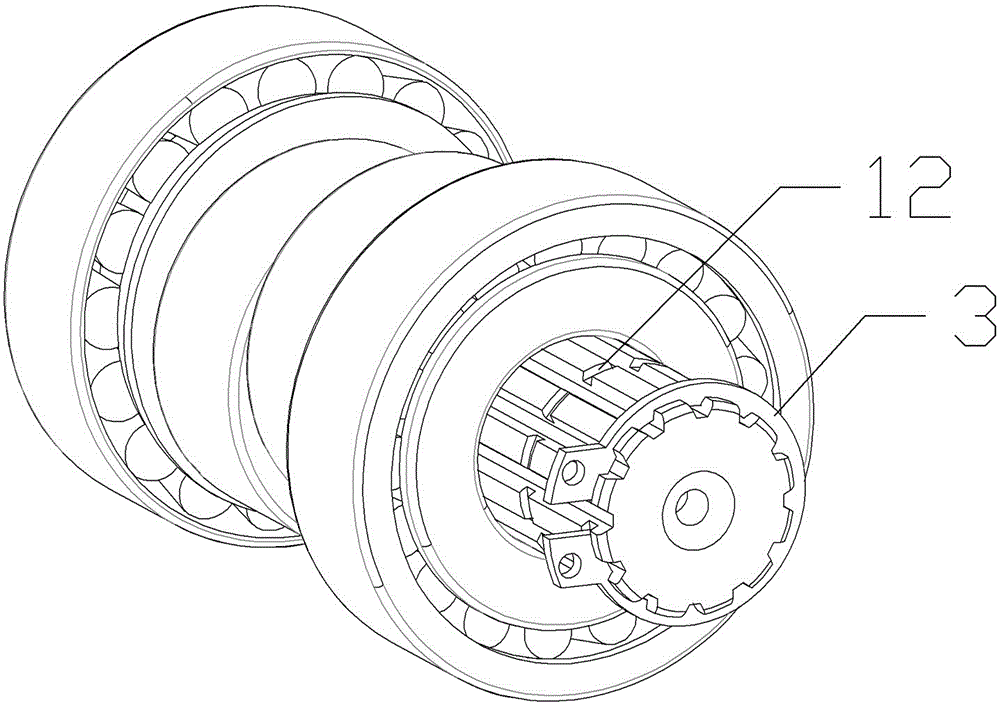

[0018] The reference signs in the drawings of the specification include: main shaft 1, driving gear 2, fourth circlip 3, third circlip 4, second bearing 5, second circlip 6, second eccentric wheel 7, eccentric wheel washer 8 , The first eccentric wheel 9, the first snap ring 10, the first bearing 11, the third ring groove 12.

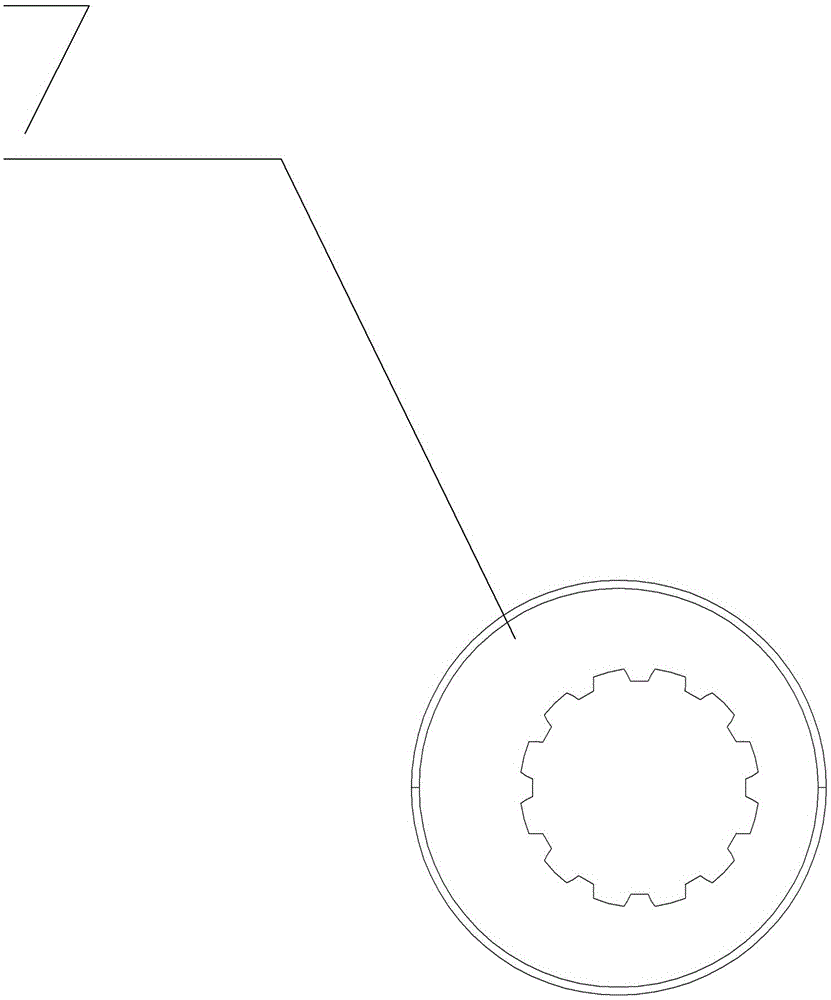

[0019] as attached figure 1 As shown, the eccentric shaft assembly used in the RV reducer in this embodiment includes a main shaft 1, and a central hole along the axial direction of the main shaft 1 is respectively opened at both ends of the main shaft 1, and holes along the axial direction of the main shaft 1 are evenly distributed on the outer periphery of the main shaft 1. The external spline of the main shaft 1 has four identical ring grooves, which are respectively the first ring groove, the second ring groove, the third ring groove 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com