Air source enhanced vapor injection heat pump system

A technology of jet enthalpy increase and heat pump system, which is applied in heat recovery system, climate sustainability, energy-saving heating/cooling, etc., can solve the problem of difficulty in realizing both heating and cooling, large compression ratio of heat pump, and frosting efficiency of evaporator. Operation and other problems to achieve the effect of reducing irreversibility, reducing compression ratio, and avoiding energy backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

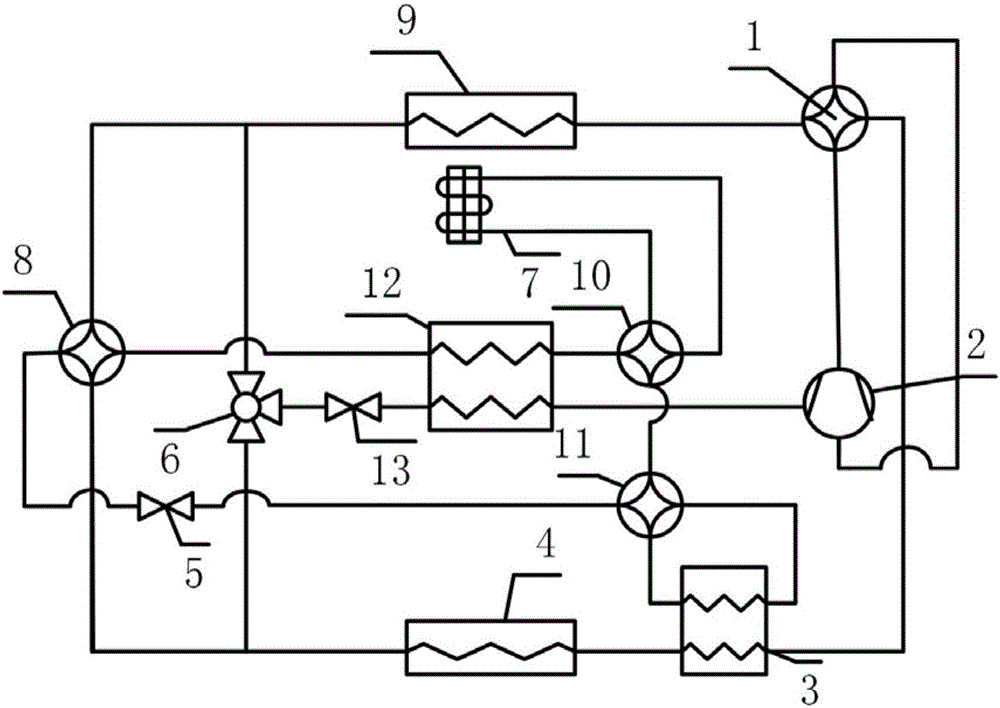

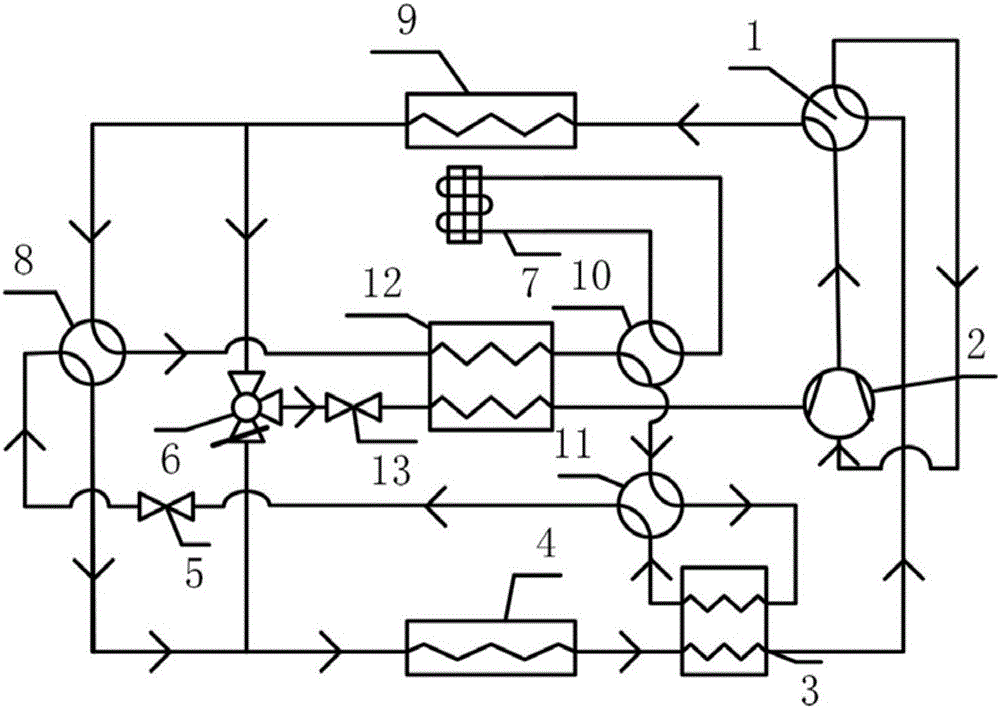

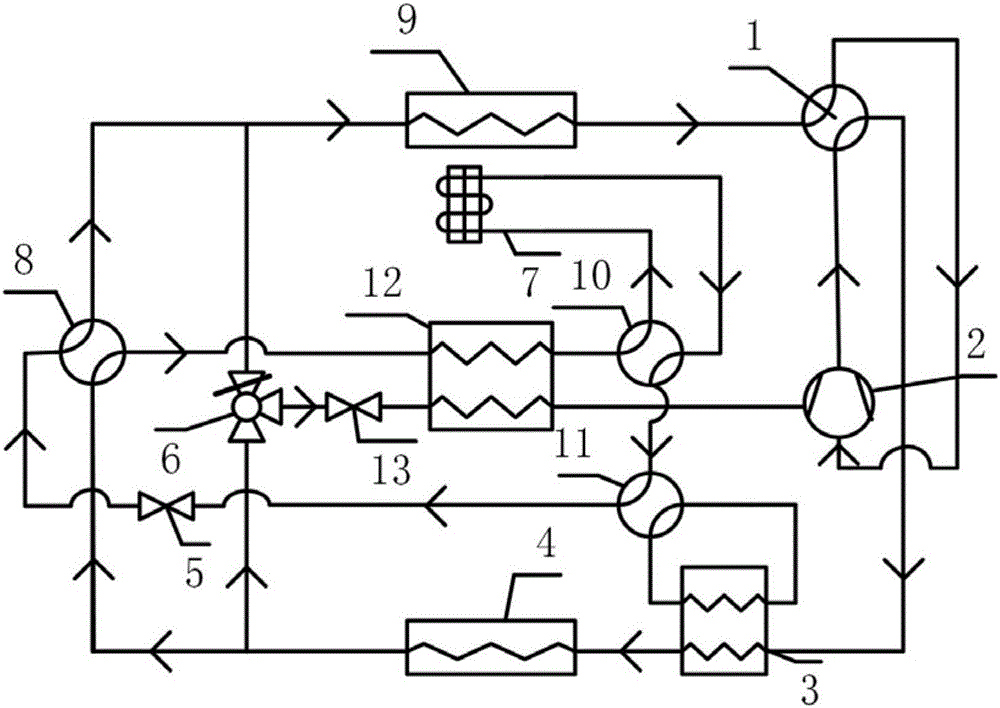

[0025] Such as figure 1 As shown, this embodiment discloses a high-efficiency dual-purpose air source air jet enthalpy-increasing heat pump system for cooling and heating, which consists of a first four-way reversing valve 1, a second four-way reversing valve 8, and a third four-way reversing valve Valve 10, fourth four-way reversing valve 11, air injection enthalpy increasing compressor 2, regenerator 3, economizer 12, first refrigerant air-cooled heat exchanger 9, second refrigerant air-cooled heat exchanger 4. The first electronic expansion valve 5, the second electronic expansion valve 13, the three-way valve 6, and the refrigerant subcooling heat exchanger 7; in this system, the first refrigerant air-cooled h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com