Single-machine two-stage screw compression ultra-large ultralow-temperature air source heat pump unit

A technology of air source heat pump and two-stage compressor, applied in the direction of compressor, compressor, irreversible cycle compressor, etc., can solve the problems of inconvenient use, increase, decrease of performance coefficient, etc. Significantly, the effect of improving the energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

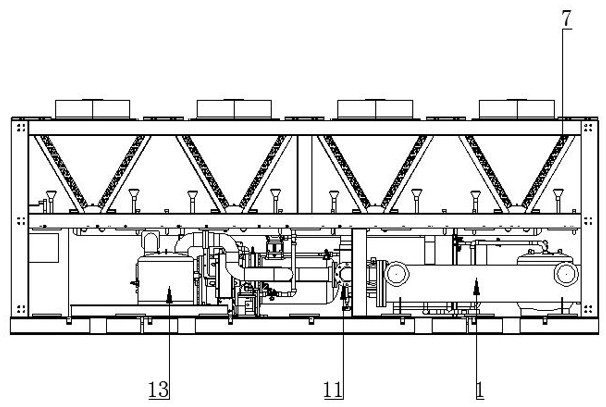

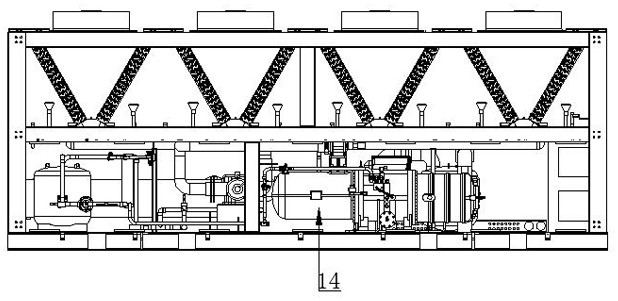

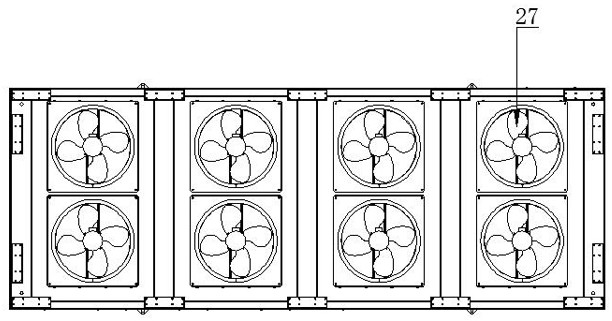

[0020] like Figure 1-Figure 4 As shown, the present invention provides a single-machine two-stage screw compression super-large ultra-low temperature air source heat pump unit, including a shell-and-tube condenser 1, an economizer 2, a high-pressure liquid accumulator 5, an evaporator 7, a fin heat exchanger 21, four Through valve 11 and single-machine two-stage compressor 14.

[0021] The shell and tube condenser 1 is provided with a cold water inlet, a hot water outlet, a refrigerant outlet and a refrigerant inlet, the cold water enters the shell and tube condenser 1 from the cold water inlet for heat exchange, and is discharged from the hot water outlet after heat exchange; The refrigerant outlet is connected to the inlet of the economi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com