High temperature flue gate, combustion furnace device with high temperature flue gate and manufacturing method of high temperature flue gate

A high-temperature flue and gate technology, which is applied in the direction of combustion method, exhaust gas device, combustion product treatment, etc., can solve the problems of poor corrosion resistance, improve high temperature resistance and corrosion resistance, improve high temperature resistance, Improve the effect of high temperature resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

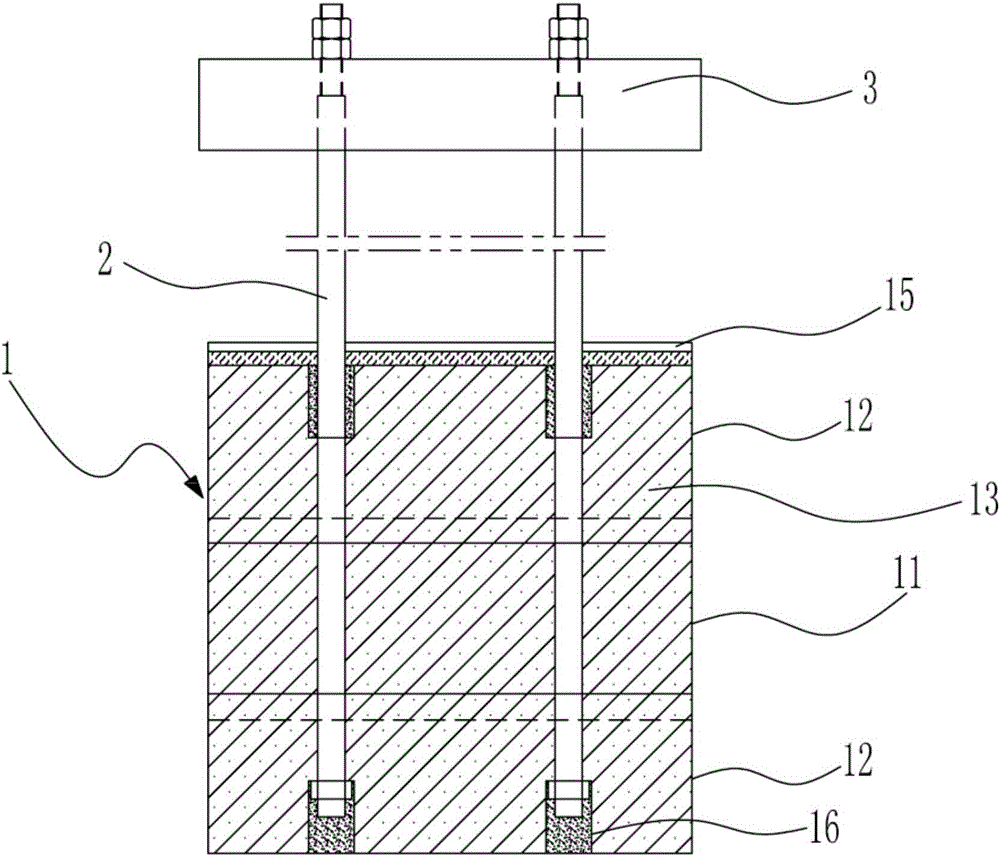

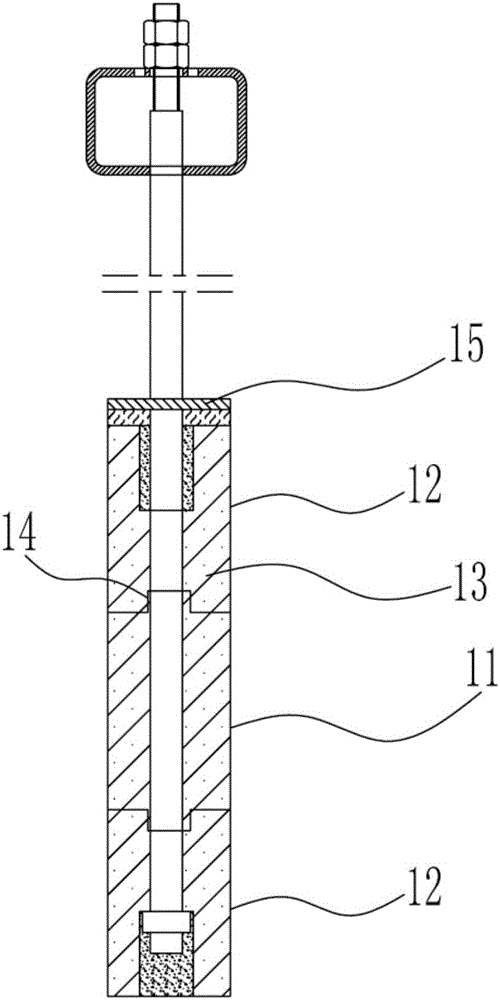

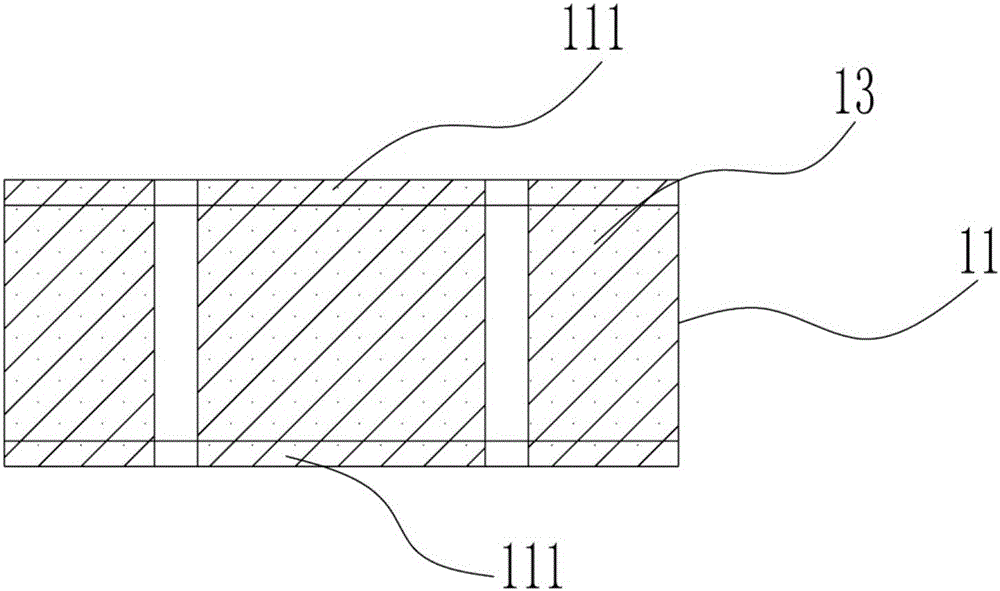

[0045] In order to achieve the purpose of the present invention, as Figure 1-5 As shown, in some of the embodiments of the high-temperature flue gate of the present invention, it includes: a gate assembly 1 (the number of which can also be provided with a plurality of independent gate assemblies or spliced to form a large gate according to the actual required area Multiple gate assemblies), the gate assembly includes a first gate unit 11 and two second gate units 12, which are rectangular, and the two second gate units 12 are detachably connected to the first gate unit 11 respectively Both sides of the first gate unit 11 and the second gate unit 12 are provided with an expanded metal layer (not shown) and a high-aluminum material layer 13, and the expanded metal layer can be specifically selected from an iron metal plate The mesh layer, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com