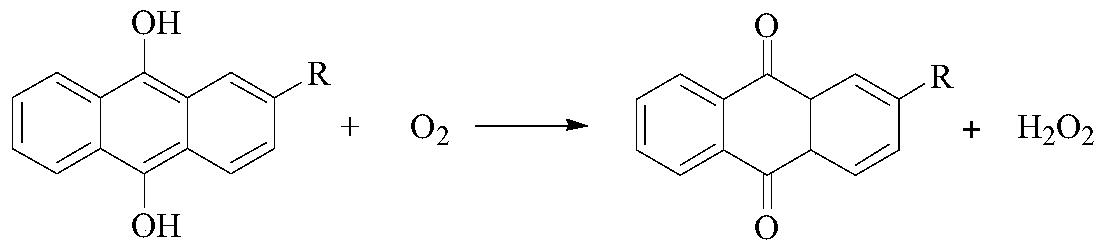

Determination method of hydrogenation efficiency, oxidation efficiency and raffinate concentration in the process of producing hydrogen peroxide by anthraquinone method

A determination method and technology of hydrogenation efficiency, applied in the field of analysis and detection, can solve the problems of inability to report analysis data in time, labor-intensive operators, and time-consuming analysis, etc., to reduce the time of direct contact with working fluid, labor-intensive, and improve Effects of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step (1): the preparation of standard titration solution: the H 2 SO 4 , Ce(SO 4 ) 2 、H 2 O is prepared in a mass ratio of 2:10:100 to obtain a standard titration solution; wherein, Ce(SO 4 ) 2 The concentration is 0.25mol / L.

[0033] Step (2): blank titration: add 10mL HCl content in titration cup and be the hydrochloric acid buffer solution of 2.5mol / L (the blank titration when measuring the hydrogenation efficiency, add 30mL heavy aromatics in addition, its main component is C8 and C9 aromatics), With the standard titration solution prepared in step (1), use a general-purpose potentiometric titrator to titrate the hydrochloric acid buffer solution, and titrate to the end point by setting the end point potential method, that is, stop the titration;

[0034] Step (3): Titration Test:

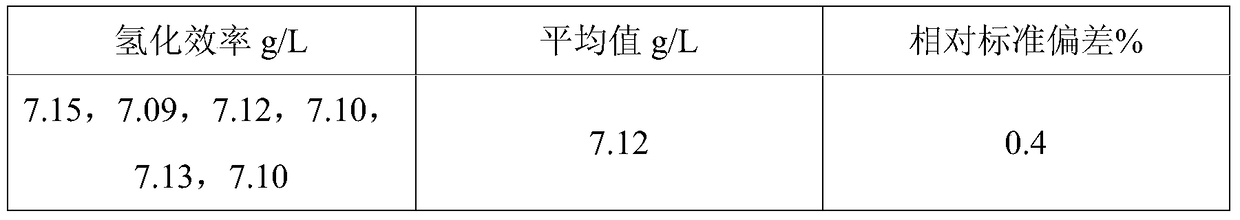

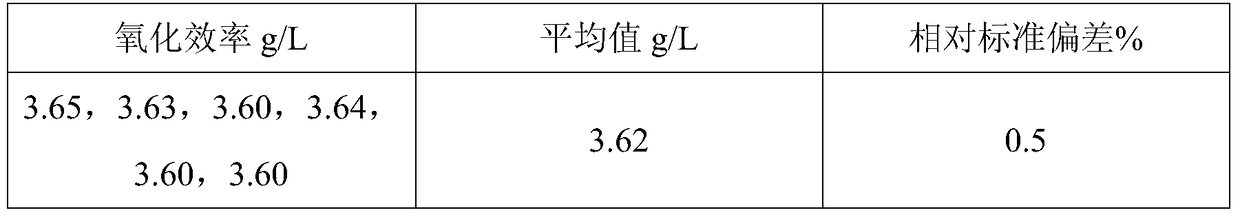

[0035] a. Determination of hydrogenation efficiency:

[0036] Add 5mL of hydrogenated liquid samples (mainly including hydroanthraquinone, trioctyl phosphate, and heavy aromatics...

Embodiment 2

[0045] Step (1): the preparation of standard titration solution: the H 2 SO 4 , Ce(SO 4 ) 2 、H 2 O is prepared in a mass ratio of 10:2:100 to obtain a standard titration solution; wherein, Ce(SO 4 ) 2 The concentration is 0.13mol / L.

[0046] Step (2): blank titration: add 15mL HCl content in the titration cup and be the hydrochloric acid buffer solution of 2.5mol / L (the blank titration when measuring hydrogenation efficiency, add 20mL heavy aromatics in addition, its main component is C8 and C9 aromatics), With the standard titration solution prepared in step (1), use a general-purpose potentiometric titrator to titrate the hydrochloric acid buffer solution, and titrate to the end point by setting the end point potential method, that is, stop the titration;

[0047] Step (3): Titration Test:

[0048] a. Determination of hydrogenation efficiency:

[0049] Add 2mL of hydrogenated liquid samples (mainly including hydroanthraquinone, trioctyl phosphate, and heavy aromatics...

Embodiment 3

[0059] Step (1): the preparation of standard titration solution: the H 2 SO 4 , Ce(SO 4 ) 2 、H 2 O is prepared in a mass ratio of 5:4:100 to obtain a standard titration solution; wherein, Ce(SO 4 ) 2 The concentration is 0.04mol / L.

[0060] Step (2): blank titration: add 10mL HCl content in titration cup and be the hydrochloric acid buffer solution of 3mol / L (blank titration when measuring hydrogenation efficiency, add 25mL heavy aromatics in addition, its main component is C8 and C9 aromatics), with The standard titration solution prepared in step (1) adopts a general-purpose potentiometric titrator to titrate the hydrochloric acid buffer solution, and titrates to the end point by setting the end point potential method, that is, stops the titration;

[0061] Step (3): Titration Test:

[0062] a. Determination of hydrogenation efficiency:

[0063] Add 0.5mL hydrogenated liquid sample (mainly including hydroanthraquinone, trioctyl phosphate, and heavy aromatics) to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com