A device and method for early warning and identification of grinding wheel broken state

An identification method and identification device technology are applied in the direction of material analysis using acoustic wave emission technology, which can solve the problems of limited impact force of the protective cavity of the rotary strength testing machine, inability to accurately detect the broken state of small fragments, and time lag. Achieve high sensitivity, reduce destructive effects, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

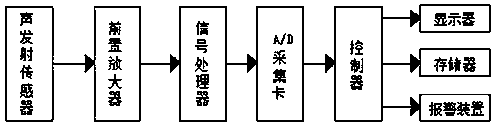

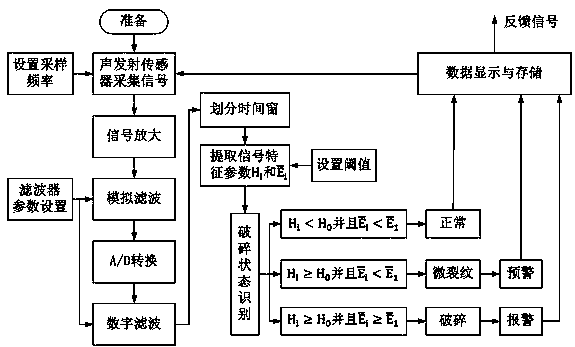

[0029] Such as figure 1As shown, the grinding wheel broken state early warning and identification device of the present invention includes an acoustic emission sensor, a preamplifier, a signal processor, an A / D acquisition card and a controller connected in sequence, an acoustic emission sensor, a preamplifier, and a signal processor , The A / D acquisition card and the controller are connected by a signal transmission line. The acoustic emission sensor is installed on the grinding wheel spindle shell through a coupling agent, and the distance between the acoustic emission sensor and the grinding wheel in the axial direction of the grinding wheel is less than or equal to 100mm. The sensor is equipped with a sealed shell to prevent pollution and signal interference. The acoustic emission sensor is used to collect the acoustic emission signal during the rotation of the grinding wheel, and output an analog voltage signal to the preamplifier, which is used to amplify the collected si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com