Method of quantitatively evaluating beneficiation flowsheet optimization degree

A quantitative evaluation and process technology, applied in the field of beneficiation technology, can solve the problems of difficulty in quantitative evaluation of the degree of optimization of the beneficiation process and the lack of quantitative evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

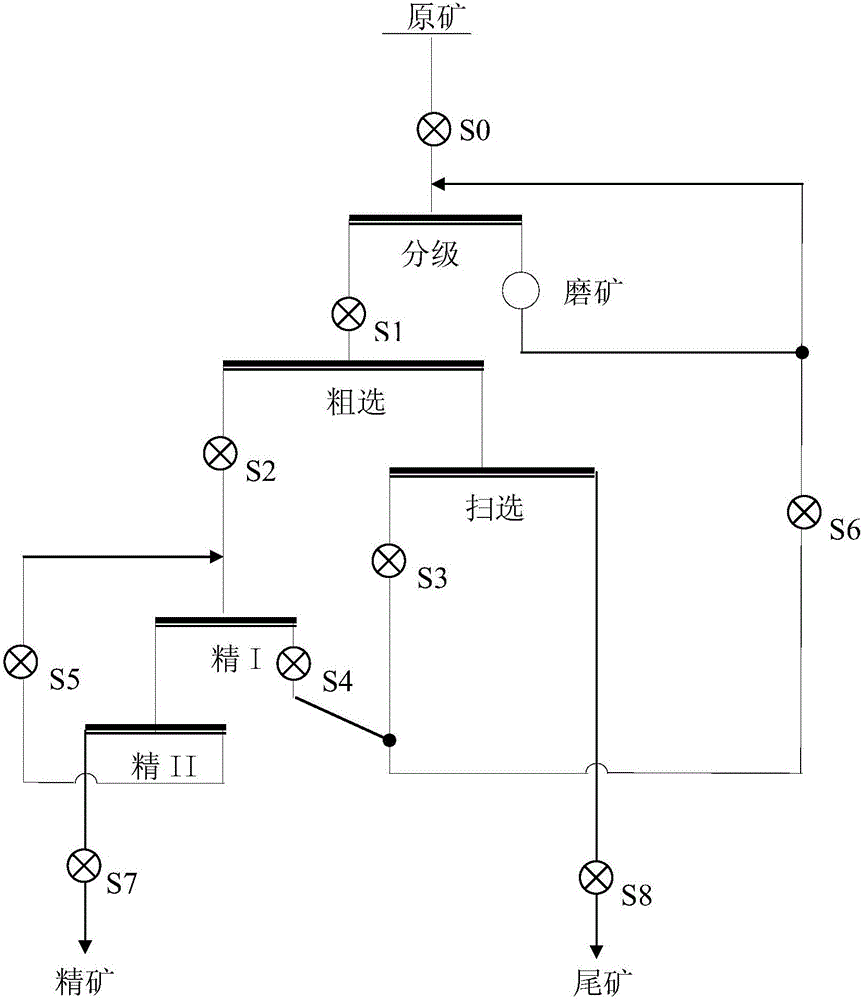

[0066] Used in a copper concentrator figure 1 The structure of the flotation process is shown, and the sampling locations include: S0 raw ore, S1 cyclone overflow, S2 roughing concentrate, S3 sweeping concentrate, S4 fine I tailings, S5 fine II tailings, S6 middle ore, S7 concentrate, S8 tailings;

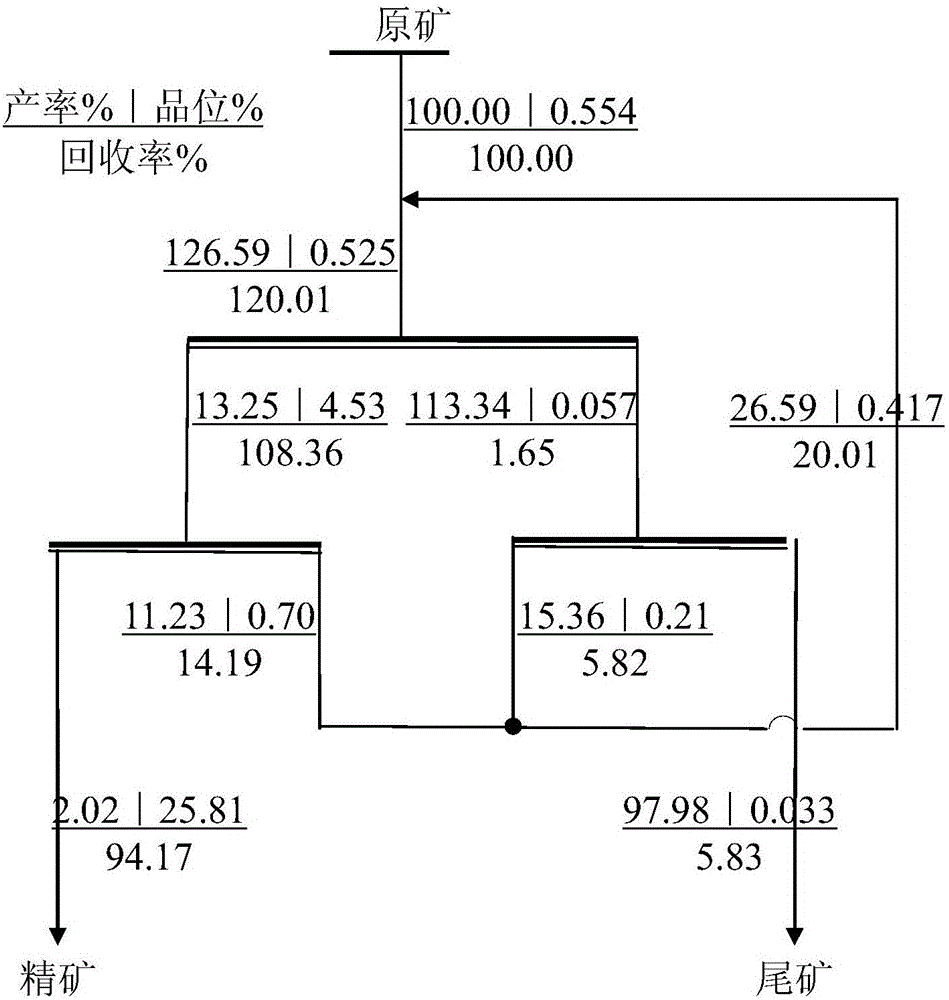

[0067] Analyze copper grade of each sample, calculate and draw image 3 The flow chart of the number and quality of the flotation process is shown, and then the recovery rate of each unit operation is calculated: roughing R u =90.29%, Sweep R n = 49.96%, select R k =86.90%, total recovery rate R=94.17%;

[0068] Calculate the sensitivity factor of the recovery rate of each unit operation, and calculate it according to the formula (5-1) ~ (5-3): ∂ R ∂ R u = 0.63 , ∂ R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com