Resin insulated dry-type oblong pancake coil and its winding method

A pancake coil and winding method technology, used in coil manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of difficult partial discharge control, small wire filling factor, and high local electric field strength, and achieve optimization. Effect of electric field strength, increasing filling factor, and equalizing electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

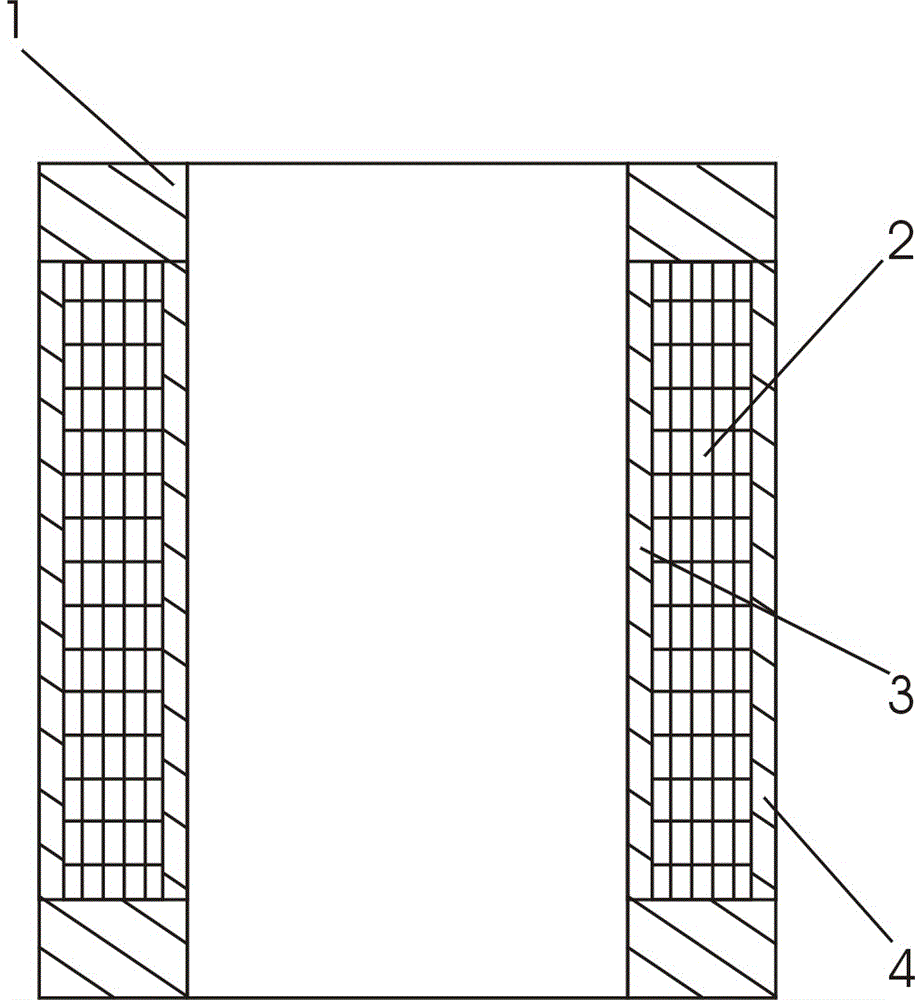

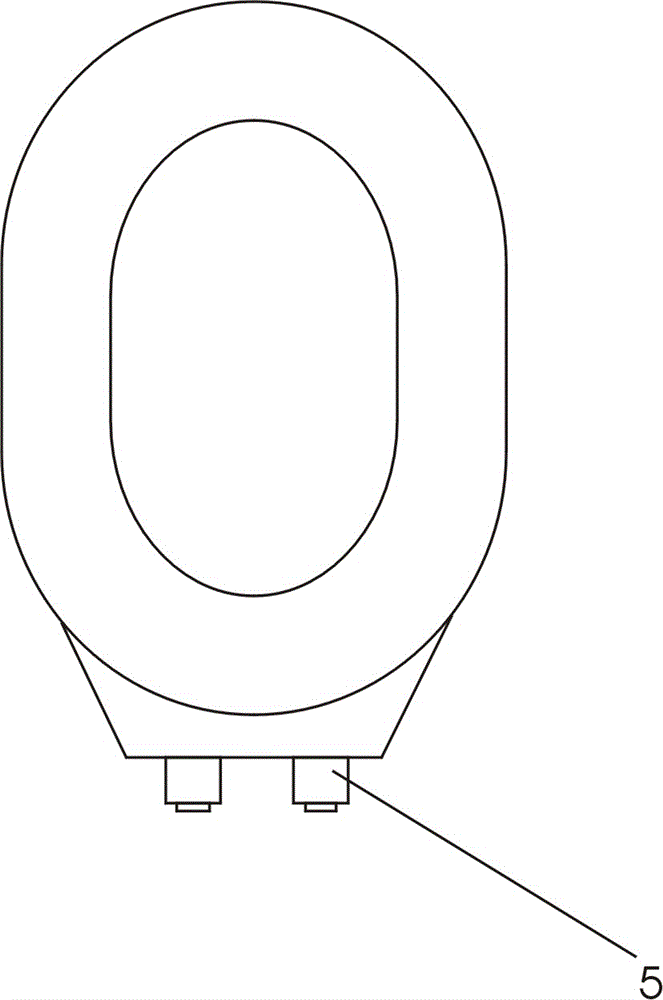

[0009] Now refer to the attached figure 1 And attached figure 2 , the resin insulated dry oblong coil of the present invention and the winding method are described as follows in conjunction with the embodiments: the resin insulated dry oblong coil of the present invention includes end insulation 1, wire 2, inner surface insulation 3 , External insulation 4 and outgoing terminal 5. The cross-section of the coil is oblong, and the cross-section of the iron core is also oblong. Compared with the iron core and coil of the traditional circular structure, when the cross-sectional area of the iron core is the same, the distance between the two iron core columns is reduced. The amount of iron core is reduced accordingly. The two ends of the coil are provided with end insulation 1 glass mesh cloth strips, and the inner surface of the coil is provided with inner surface insulation 3 glass mesh cloth, and the surface of the inner surface insulation 3 glass mesh cloth is wrapped with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com