Double-rotor electromagnetic heating machine

An electromagnetic heat engine, dual rotor technology, applied in electrical components, electromechanical devices, induction heating, etc., can solve the problems of difficult processing, complex structure, low utilization rate of rotor permanent magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

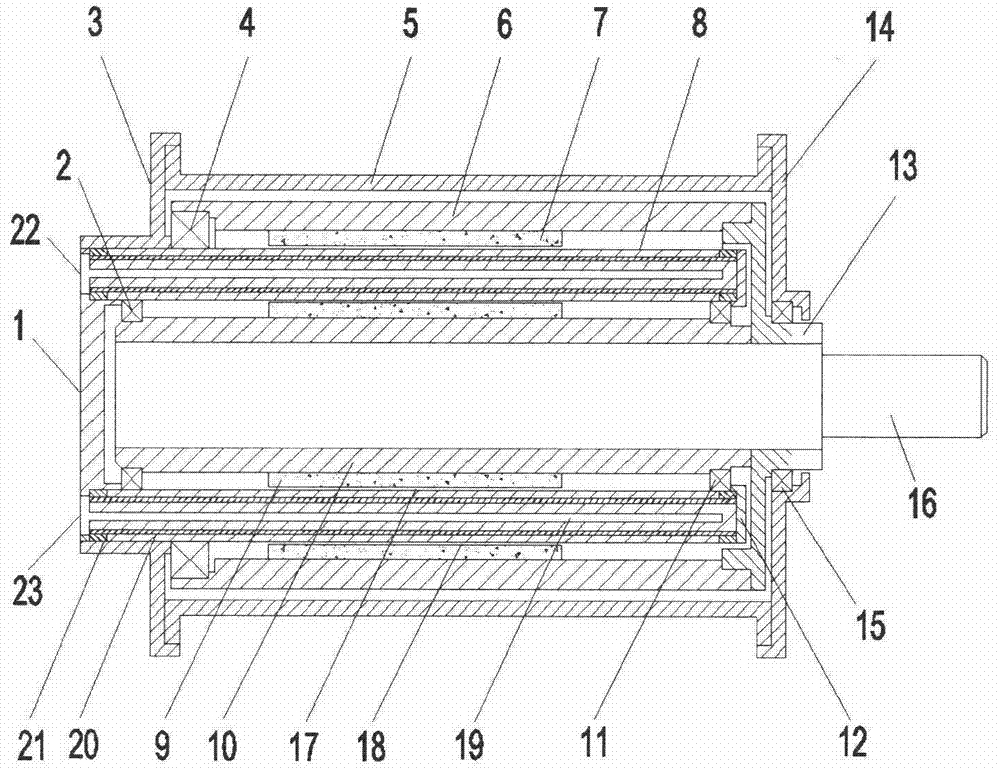

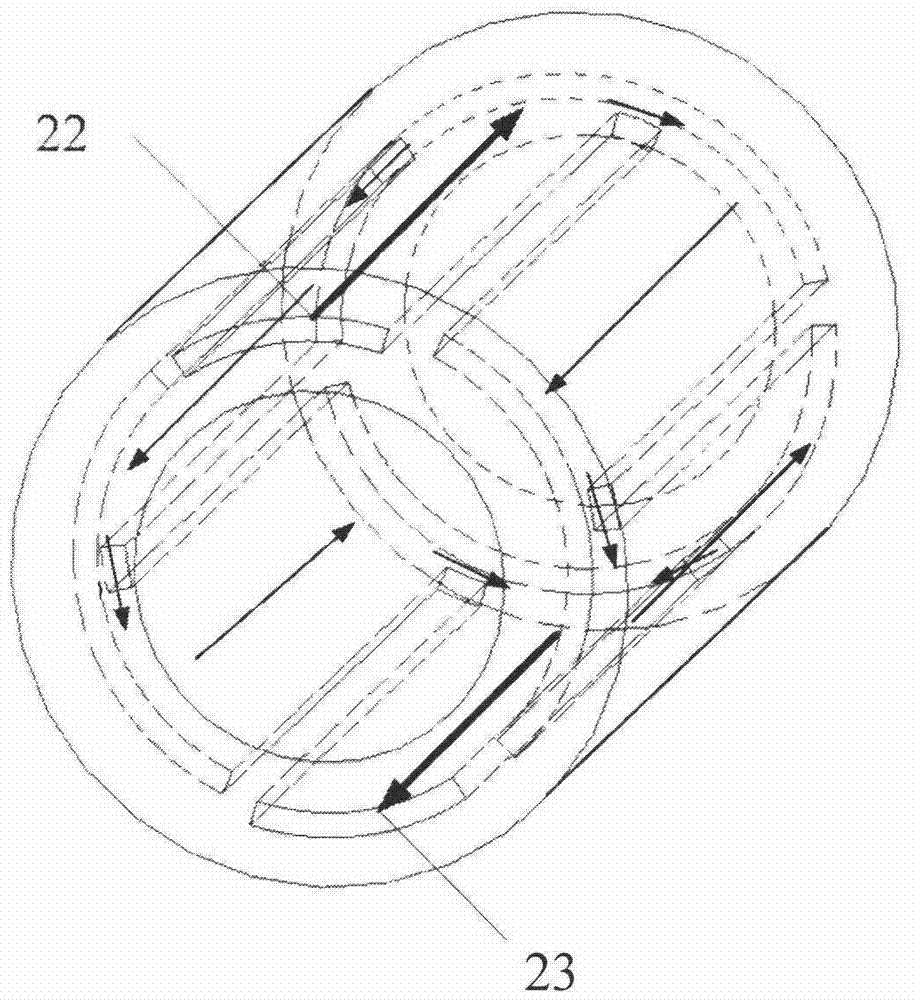

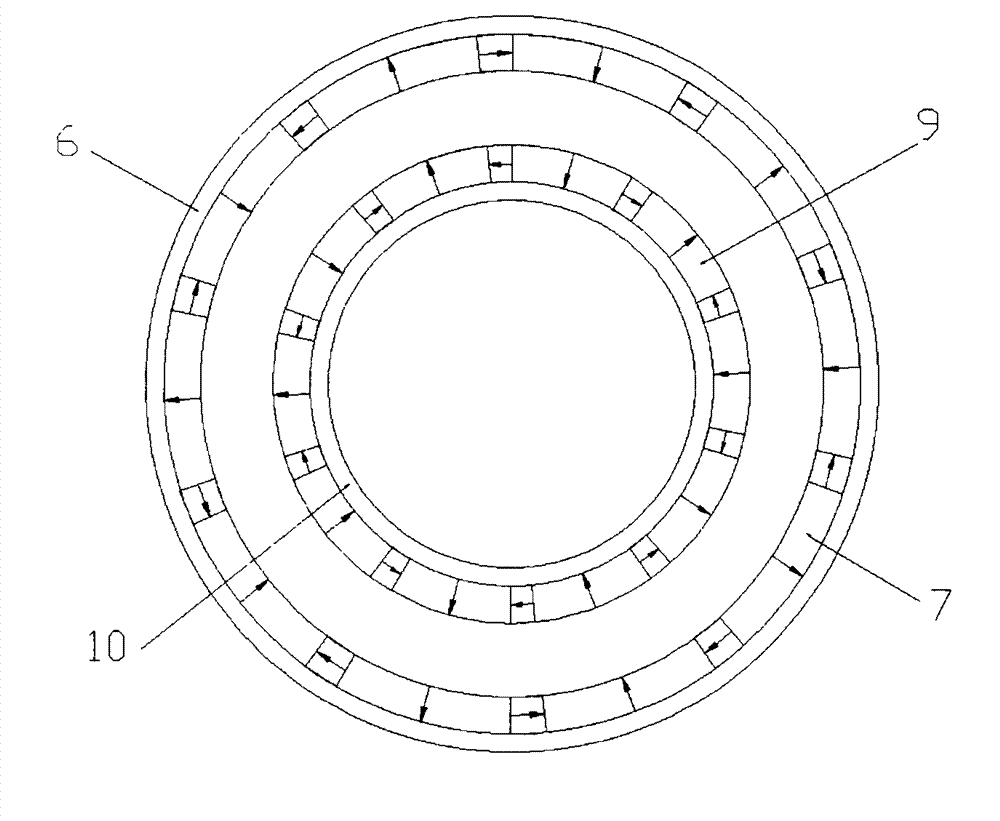

[0035] The present invention mainly consists of a first end cover (1), a first bearing (2), a first support (3), a second bearing (4), a casing (5), an outer rotor (6), and an outer circumferential permanent magnet ( 7), stator core (8), inner circumferential permanent magnet (9), inner rotor (10), third bearing (11), second support (12), third support (13), second end cover (14), fourth bearing (15), rotating shaft (16), inner air gap (17), outer air gap (18), heat exchange pipe (19), conductor (20), short circuit ring (21), inlet (22), export (23) form. The rotor and stator in the present invention can be made of massive magnetic materials such as 10# steel, or silicon steel sheet magnetic materials such as DW-315; aluminum alloy or stainless steel can be used for shells, end covers, supports, and shaft parts. ; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com