Total-reflection laser bonding disassembling method

A technology of debonding and total reflection, applied in the field of debonding, which can solve the problem that the risk of device wafer separation and debris cannot be effectively solved, the wafer separation viscosity cannot be tolerated, and the mechanical strength of device wafers is low, so as to reduce the risk of debris. , easy to operate, adaptable to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific drawings and embodiments.

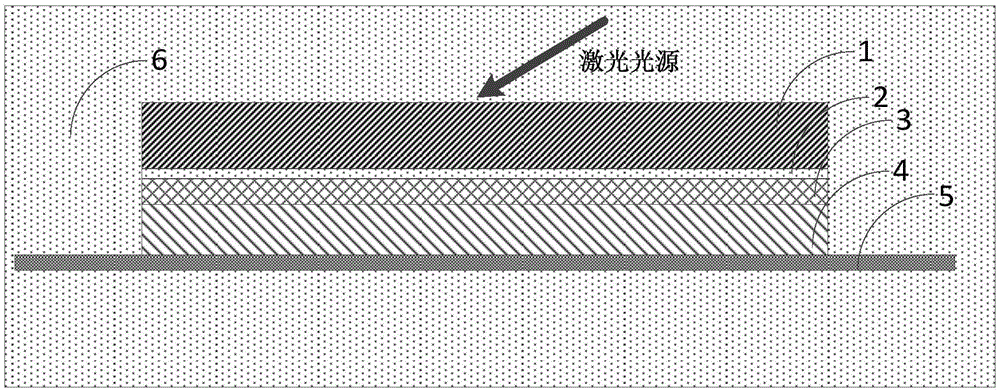

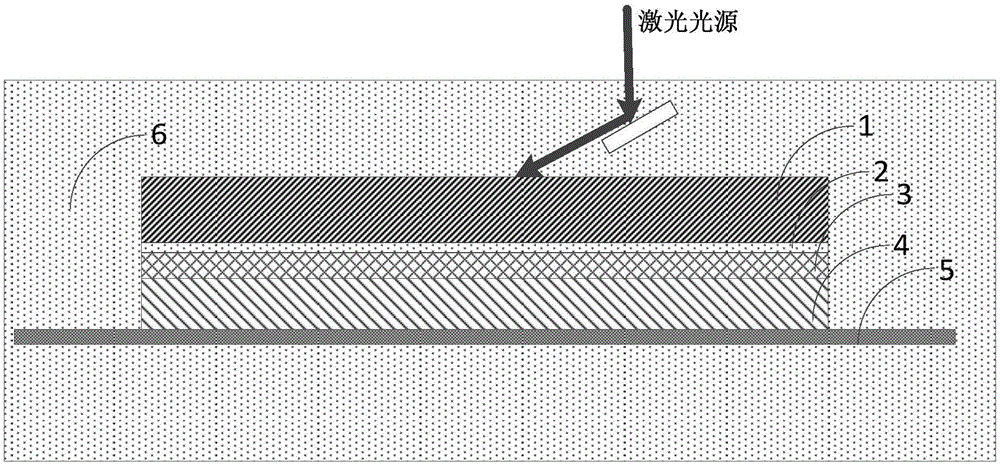

[0029] like Figure 1 to Figure 5 Shown: In order to effectively reduce the risk of fragmentation of ultra-thin device wafers during the dismantling and separation process, the dismantling and bonding method of the present invention includes the following steps:

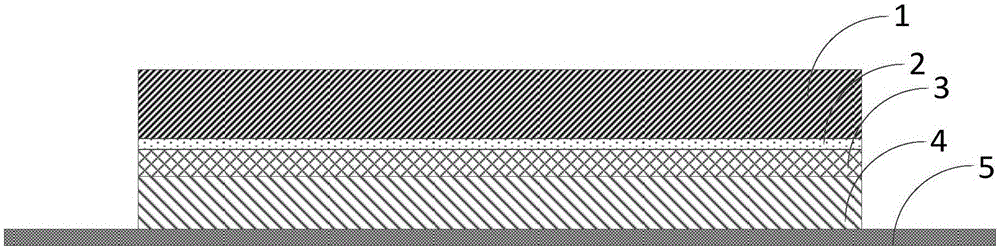

[0030] Step S1, providing a temporary bonding body to be disassembled and placing the temporary bonding body in the dismantling liquid 6; the temporary bonding body includes a device wafer 4 and a carrier located above the device wafer 4 Wafer 1, the carrier wafer 1 is bonded to the front surface of the device wafer 1 through a sacrificial layer 2 and a bonding adhesive layer 3;

[0031] like figure 1 As shown, during general implementation, the temporary bonding body also includes a debonding film 5, and the back side of the device wafer 4 is supported on the debonding film 5, and the device wafer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com