Fine pitch copper cylinder dimpling point preparation technology

A preparation process and micro-bump technology, which is used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as low efficiency and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings.

[0031] The fine-pitch copper pillar micro-bump preparation process comprises the following steps:

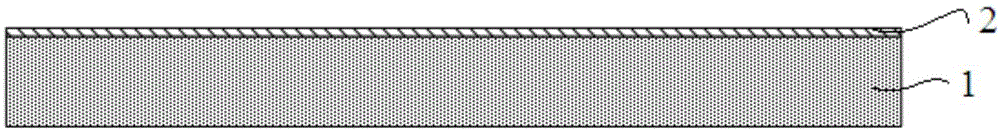

[0032] (1) if figure 1 As shown, a Ti / Cu seed layer 2 is electroplated on the surface of the wafer 1, and the thickness of the Ti / Cu seed layer 2 is 100-300 nm;

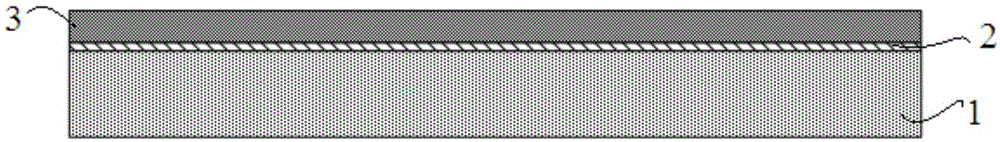

[0033] (2) if figure 2 As shown, the copper layer 3 is deposited on the surface of the Ti / Cu seed layer 2 by means of electroless plating or electroplating, and the thickness of the copper layer 3 is set according to needs, generally 10-100 μm;

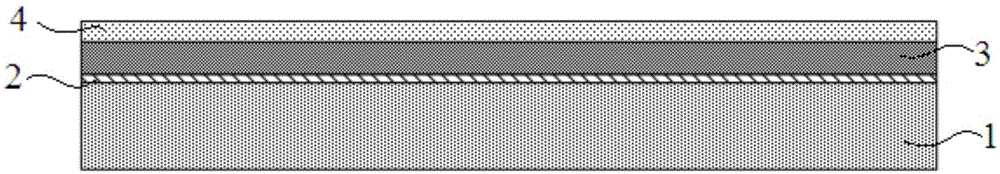

[0034] (3) if image 3 As shown, a solder layer 4 is prepared on the surface of the copper layer 3, the thickness of the solder layer 4 is 10-100 μm, and the material of the solder layer 4 is SnPb, SnAg, SnAgCu, SnBi or ternary or multi-component solder with alloy elements added ;

[0035] (4) if Figure 4 As shown, a photoresist layer 5 is coated on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com