Deflection voltage electric composite materials

A flexural voltage-electric, composite material technology, applied in circuits, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the problems of reduced material bearing capacity and narrowed use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

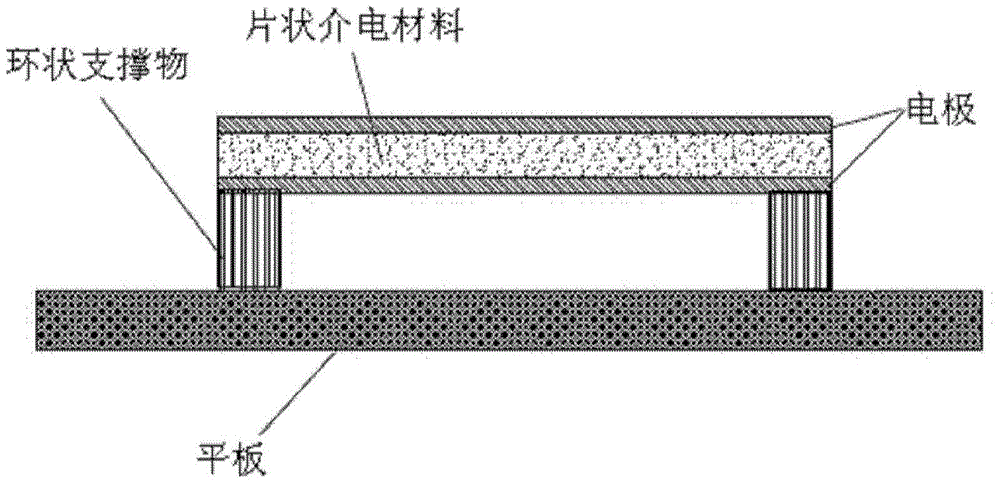

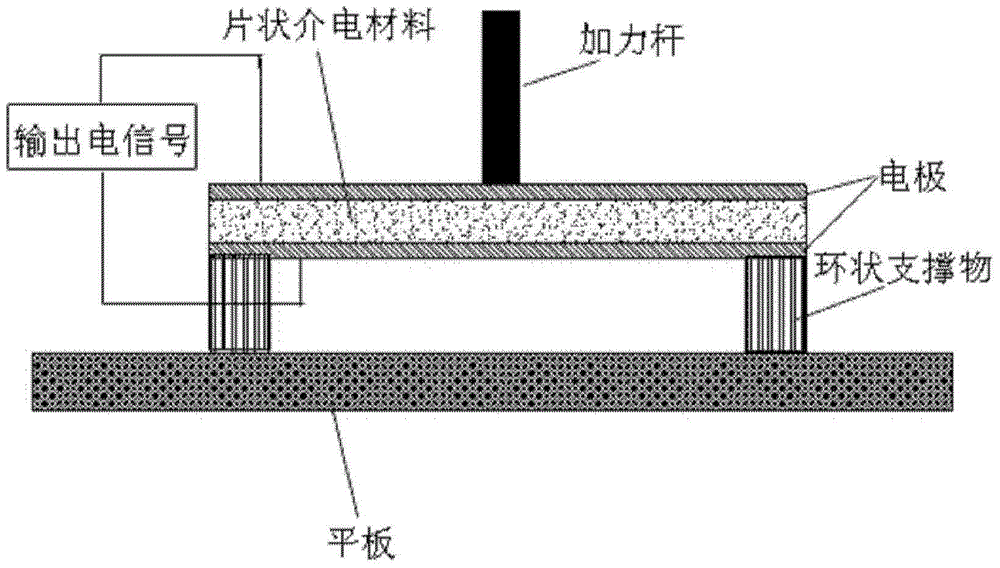

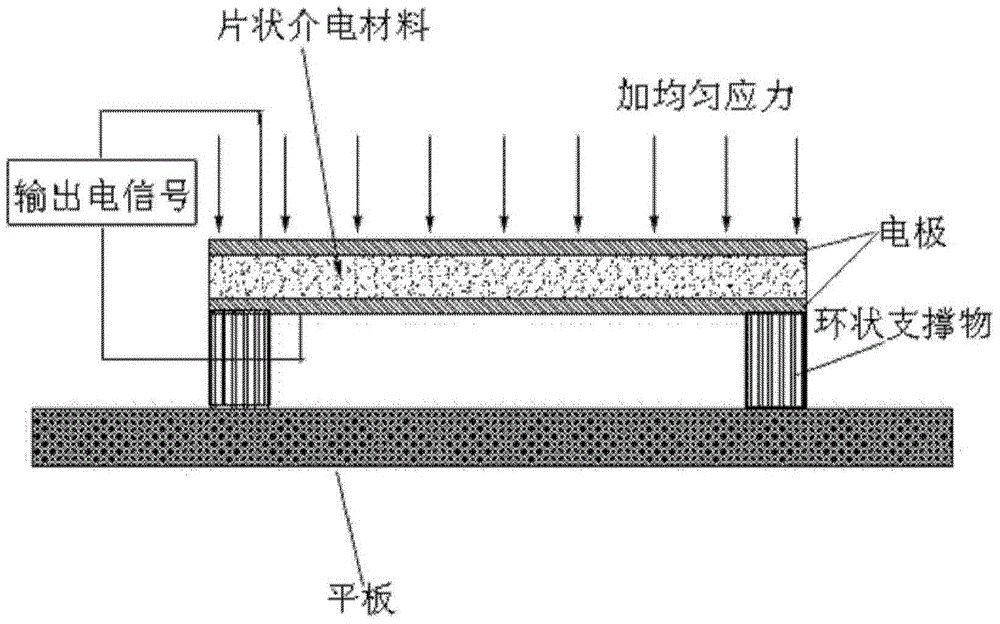

[0029] Embodiment 1: Utilize the purchased soft ferroelectric ceramic lead zirconate titanate (PZT-51) (Zibo Bailing Functional Ceramics Co., Ltd.), with a diameter of 25 millimeters and a thickness of 0.5 millimeters, to grind both sides of the ceramics flat, and use ions on both sides Gold electrodes are plated by sputtering, and then placed on a ring with a diameter of 20 mm and a flat plate with a side length of about 30 mm, and a little force is applied to the upper surface of the ceramic sheet, using ZJ-6A quasi-static d 33 The apparent piezoelectric performance of 38pC / N was obtained by instrument measurement.

Embodiment 2

[0030] Embodiment 2: utilize traditional solid-phase synthesis method to prepare 0.92Na 1 / 2 Bi 1 / 2 TiO 3 -0.08BaTiO 3 ceramics. A certain percentage of Bi 2 o 3 , Na 2 CO 3 , BaCO 3 ,TiO 2 (Analytical grade, Sinopharm Group) was added into alcohol ball mill for 6-8 hours, dried, and synthesized at 850°C for 2 hours. Then the synthesized powder is ball-milled, added with a suitable binder, pressed into a disc with a diameter of 25.4 mm, kept at 1180-1200° C. for 1 hour and sintered with a diameter of about 21 mm. Grind both sides of the ceramic sheet to a thickness of about 0.5 mm, plate gold electrodes on both surfaces by ion sputtering, and then place them on a ring with a diameter of 20 mm and a flat plate with a side length of about 30 mm , using the ZJ-6A quasi-static d 33 The apparent piezoelectric performance of 2-3pC / N was measured by the instrument.

Embodiment 3

[0031] Example 3: BaTiO prepared by traditional solid-phase synthesis 3 ceramics, a certain proportion of BaCO 3 ,TiO 2(Analytical grade, Sinopharm Group) was added into alcohol ball mill for 6-8 hours, dried, and synthesized at 1200°C for 2 hours. Then ball mill the synthesized powder, add appropriate binder, and press it into a disc with a diameter of 25.4 mm. After sintering at 1300°C for 2 hours, the diameter is about 21 mm, and the ceramic sheet is ground on both sides to a thickness of about 0.5 mm, gold electrodes are plated on both surfaces by ion sputtering, and then placed on a ring with a diameter of 20 mm and a flat plate with a side length of about 30 mm, using ZJ-6A quasi-static d 33 The apparent piezoelectric performance of 60-100C / N is obtained by instrument measurement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com