Method of forming memory element

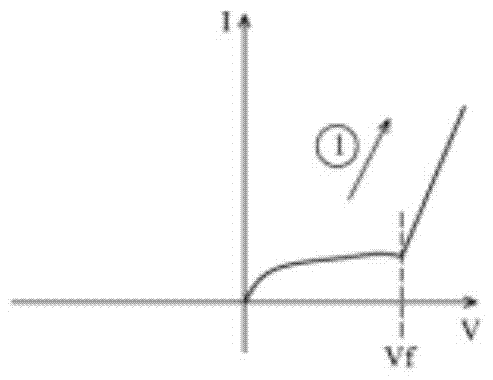

A technology of memory components and resistance conversion layers, which is applied in the direction of electrical components, can solve the problems of low pass rate and efficiency of resistive non-volatile memory, and achieve the goal of setting current stability, improving efficiency, and improving pass rate and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

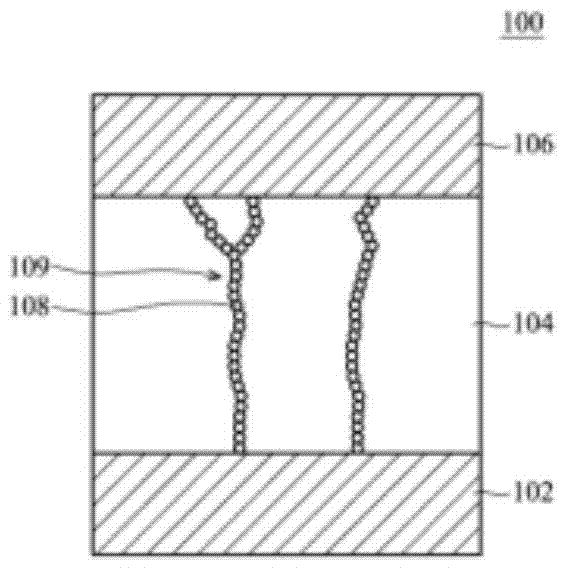

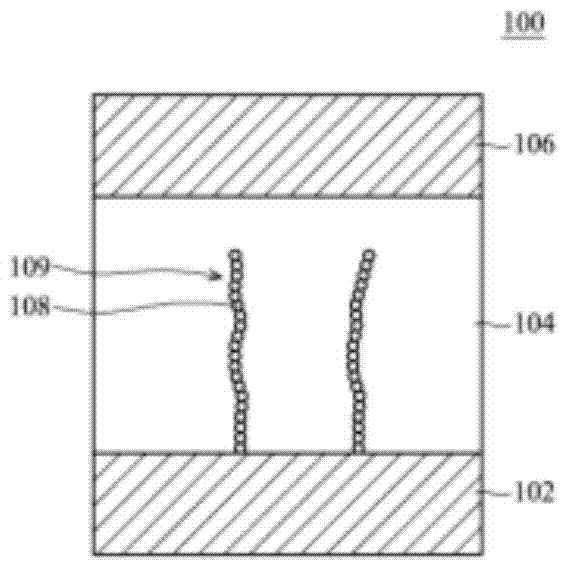

[0025] The fabrication and use of the embodiments of the present invention will be described in detail below. It should be noted, however, that this application presents many applicable inventive concepts, which can be embodied in a wide variety of specific forms. The specific embodiments listed herein are only the specific ways of making and using the present invention, and are not intended to limit the protection scope of the present invention. In addition, in practical applications, the execution of the first manufacturing process and the second manufacturing process may include the situation where the second manufacturing process is performed immediately after the first manufacturing process, or may include In the case of additional manufacturing processes. Elements may be arbitrarily drawn in different scales. This is done merely for simplicity and clarity of drawing the various elements. In addition, when a first material layer is located on a second material layer, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com