Lead-acid storage battery and electric car using such lead-acid storage battery

A lead-acid battery, single battery technology, applied in the direction of lead-acid battery, lead-acid battery construction, electric vehicles, etc., can solve the problem that the sealing ring or the sealing ring is not installed in place, the installation of the sealing ring increases the installation process, and affects the normal use of the battery. and other problems, to achieve the effect of improving production efficiency, improving connection stability, and shortening the current path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

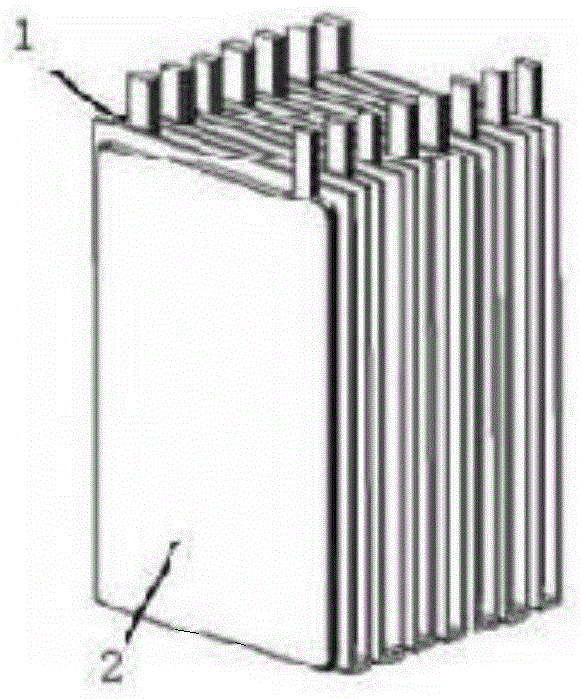

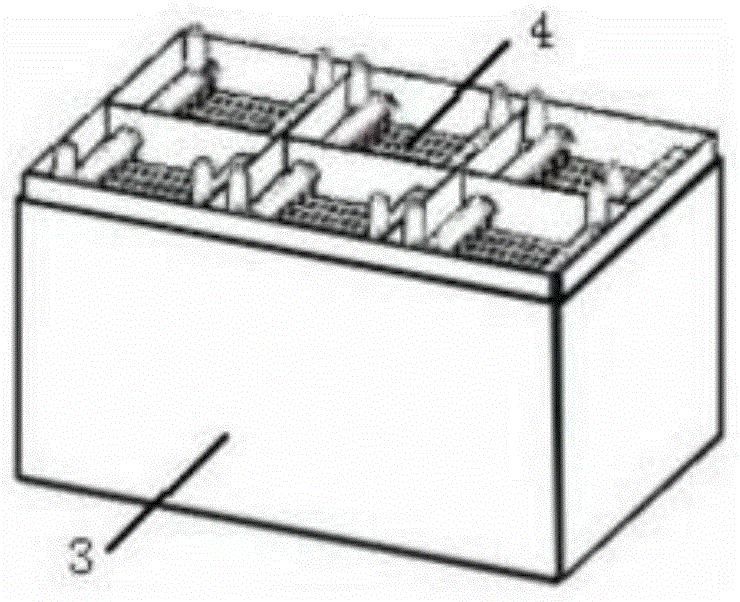

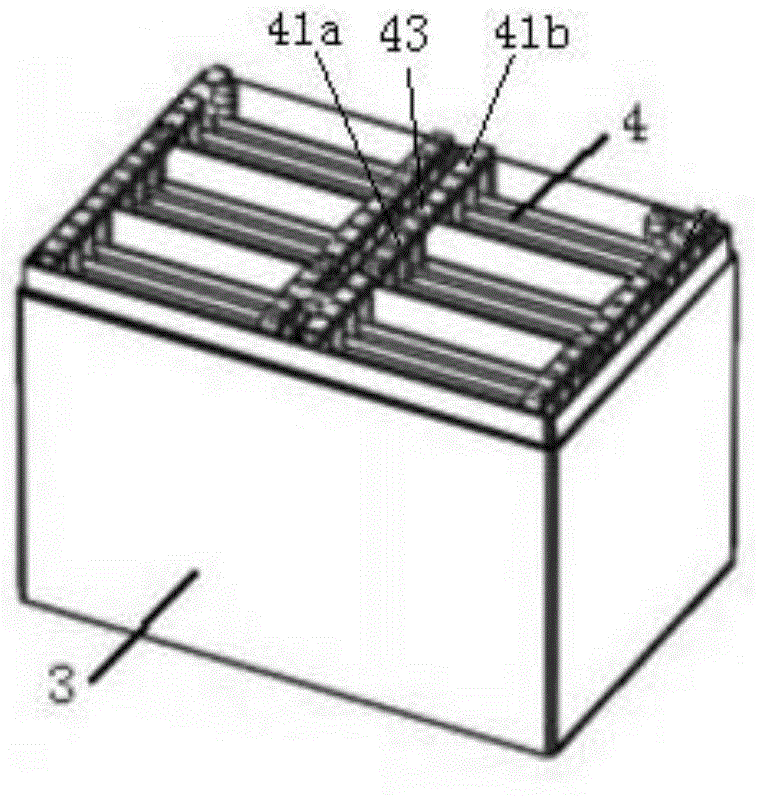

[0049] Embodiment 1: as figure 2 , Figure 4 , Figure 6 , Figure 8 , Figure 14 As shown, a lead-acid storage battery includes a positive terminal 11a, a negative terminal 11b, a positive end lead-out pole 42a, a negative end lead-out pole 42b, a cover sheet, a battery case 3 with an open upper end, and a sealed battery case The upper cover 10 of the port on the body and a number of single cells arranged side by side in the battery case. Each single battery includes a single battery slot 31 and an electrode group 4 disposed in the single battery slot. The single cell slots are evenly arranged and distributed in the battery case. The pole group is formed by a number of positive plates 1 and a number of negative plates 2 alternately arranged through separators.

[0050] The positive tabs on the positive plates of the same pole group are connected through the positive bus bar 41a, and the negative tabs on the negative plates of the same pole group are connected through t...

Embodiment 2

[0061] Embodiment 2, the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

[0062] The thickness of each positive plate is greater than the thickness of each negative plate. Such as Figure 8 As shown, the ratio of the cross-sectional area of the positive tab 1a on each positive plate 1 to the cross-sectional area of the negative tab 2a on each negative plate 2 is greater than or equal to 0.59 and less than or equal to 0.74. The ratio of the cross-sectional area of the positive tab to the cross-sectional area of the negative tab on each negative plate is 0.59 or 0.62 or 0.64 or 0.68 or 0.7 or 0.72 or 0.74. The ratio of the sum of the cross-sectional areas of the positive tabs on each positive plate to the sum of the cross-sectional areas of the negative tabs on each negative plate is greater than or equal to 0.62 and less than or equal to 0.7. In this embodiment, the ratio of the sum of the cross-sectional areas of the ...

Embodiment 3

[0064] Embodiment 3: This embodiment provides an electric vehicle, which includes a lead-acid battery described in any one of Embodiments 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com