Dielectric-filled circular waveguide circularly polarized antenna

A technology of medium-filled waveguide and circularly polarized antenna, which is applied in the direction of antenna grounding switch structure connection, radiation element structure, etc., can solve the problem of few technical means for medium-filled waveguide antenna circular polarization, and achieve good consistency and reduce Small transition lengths, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

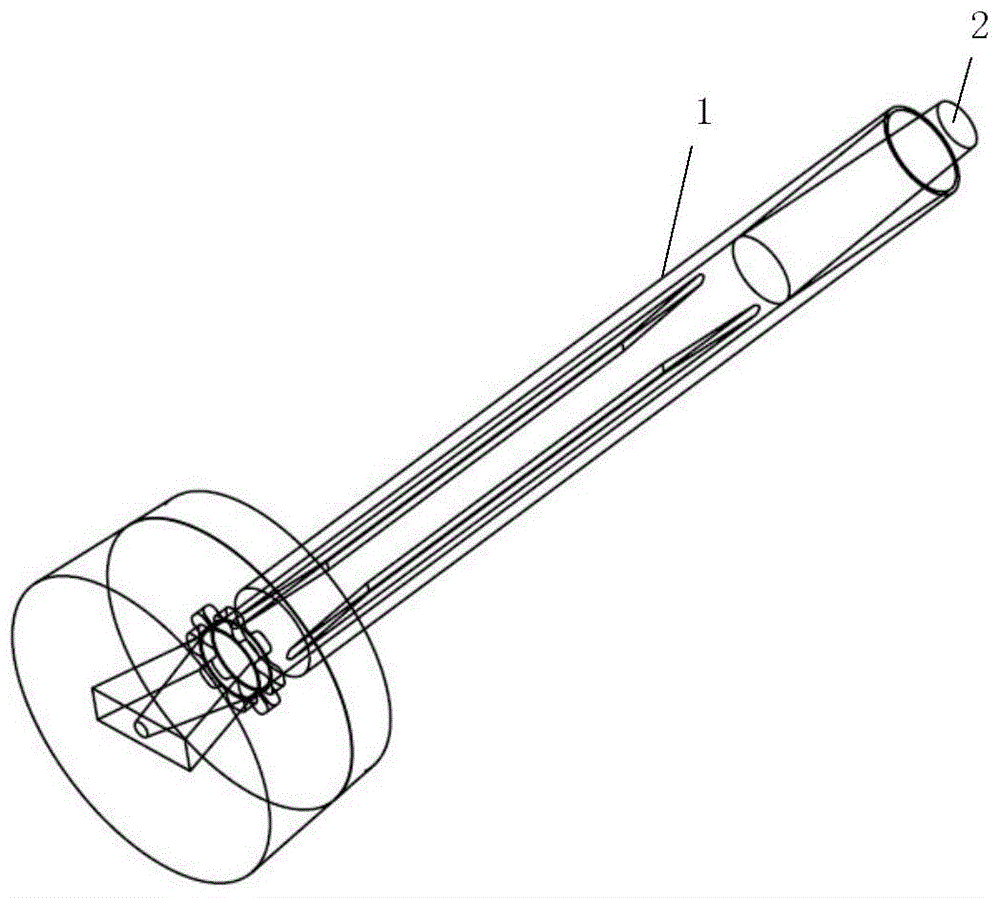

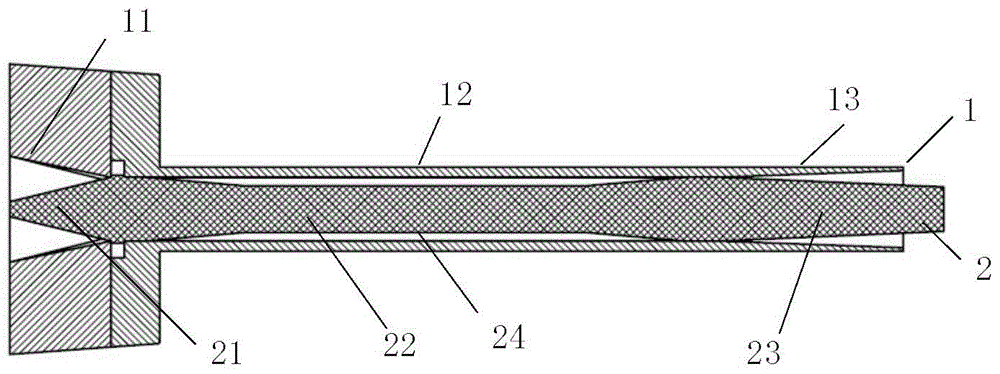

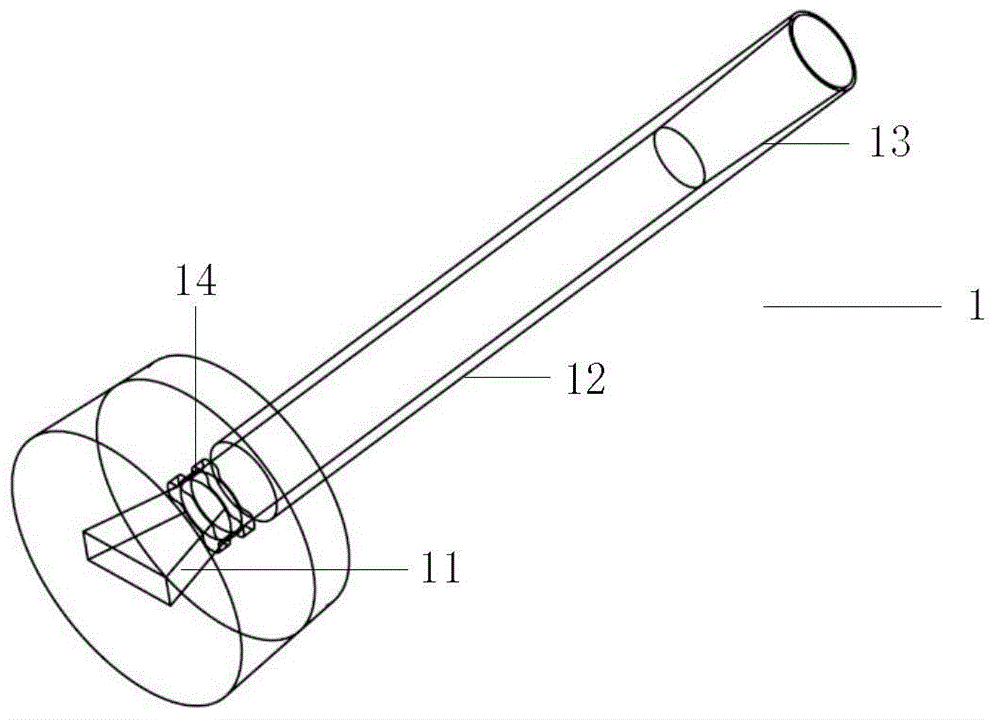

[0020] refer to Figure 1-Figure 3 . In an embodiment described below, a dielectric-filled waveguide circularly polarized antenna includes a hollow waveguide cavity 1 with a cylindrical platform, and a dielectric rod 2 with a mounting flange. Wherein, the feeding end and the radiating end of the dielectric rod (2) adopt a tapered tapered structure to realize matching. The waveguide cavity 1 is formed by connecting a dielectric circular waveguide and a conical horn. The rear end of the waveguide cavity 1 is formed with a circular frustum and a tapered tapered waveguide 11 at the center of the circular frustum. The tapered tapered waveguide with a rectangular end face transitions to a circular waveguide cavity 12. After the extension section, the conical horn 13 is connected to form the antenna feeding section. The feeding end of the rear section of the dielectric rod 2 filled in the waveguide cavity 1 is formed with a conical gradient feeding matching section 21, and the radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com