Leakage-proof machining equipment

A processing equipment and leak-proof technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem that the coolant affects the environment of the machine tool, and achieve the improvement of processing accuracy, cost reduction and adjustment accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

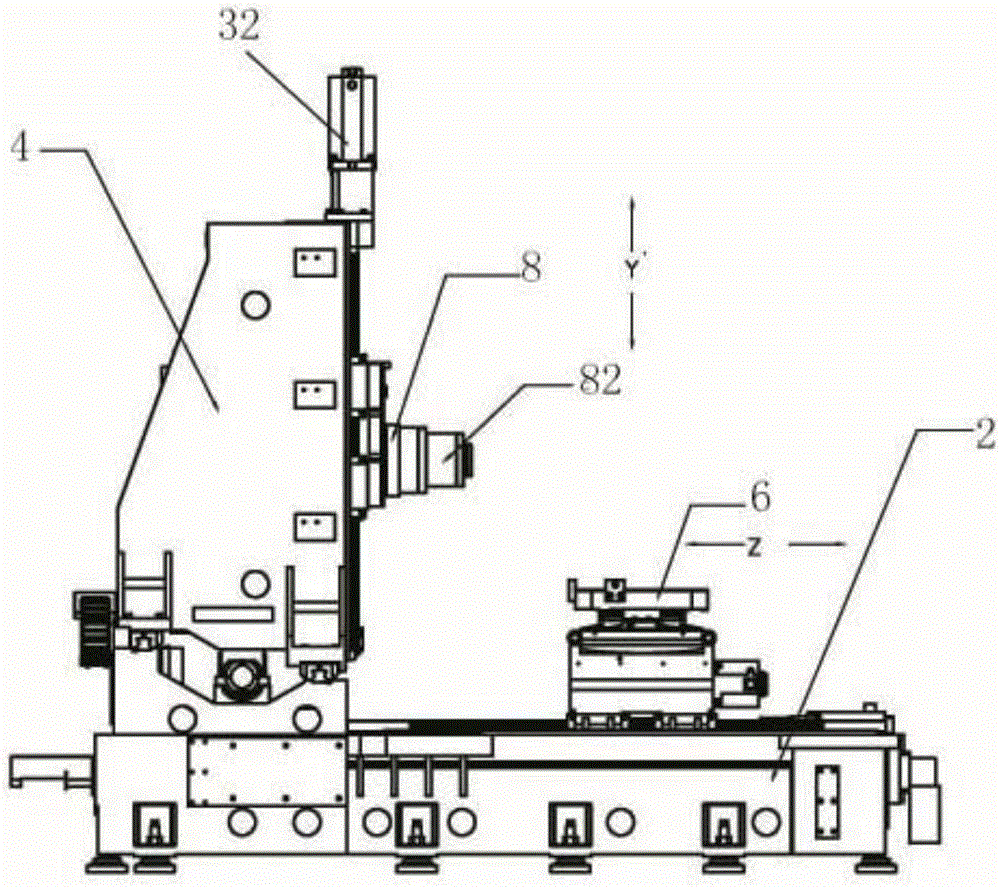

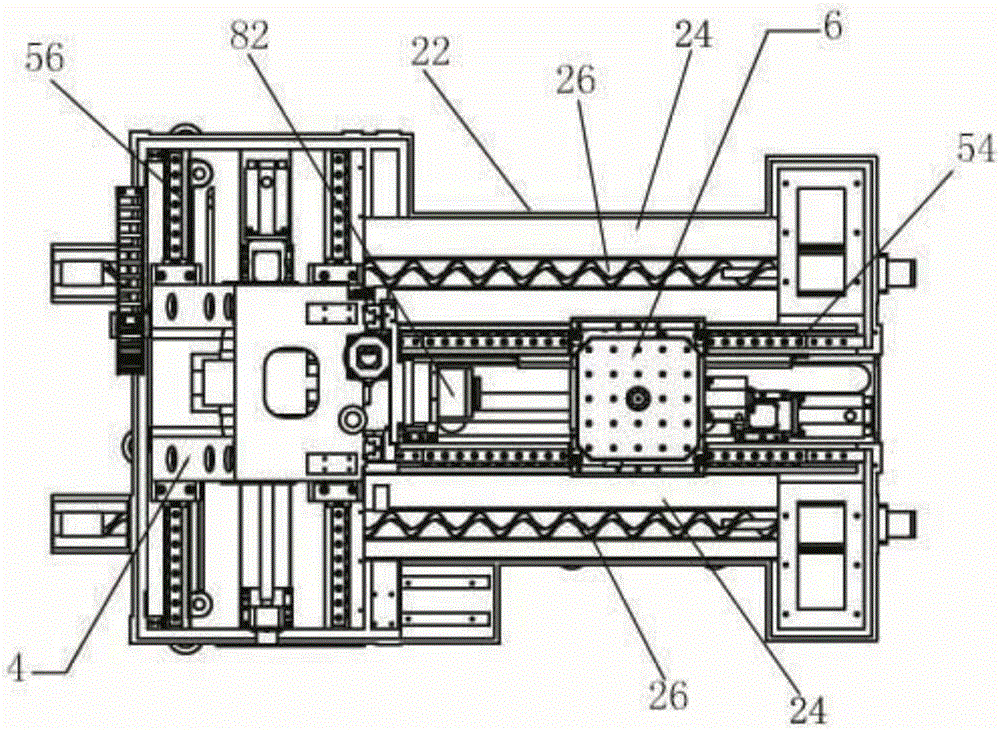

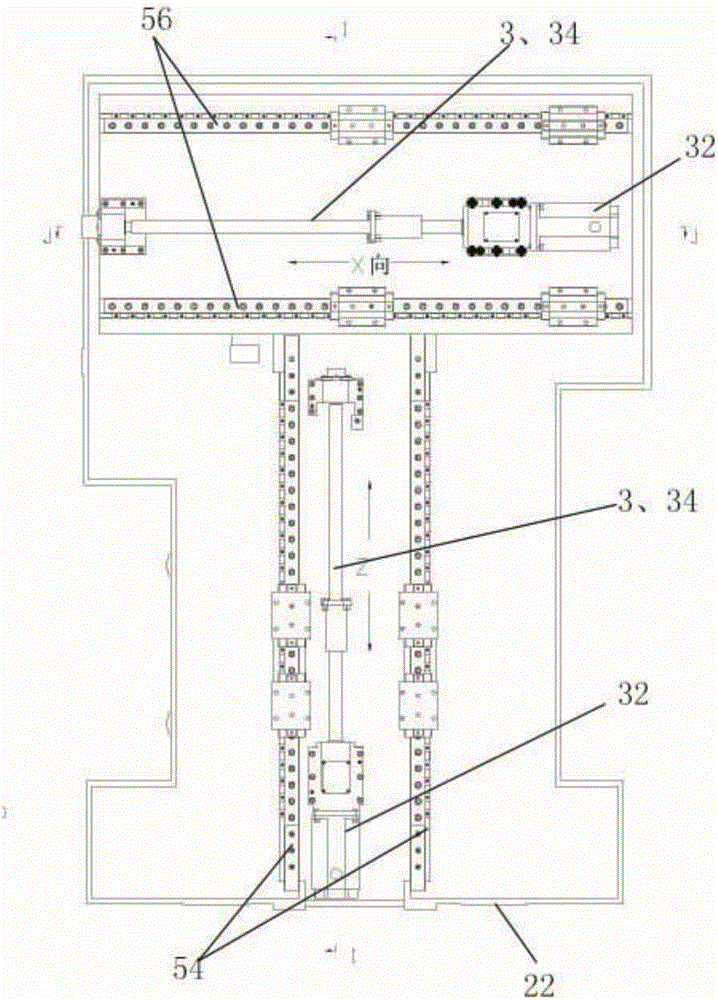

[0028] see Figure 1-5 , a leak-proof processing device according to a preferred embodiment of the present invention, comprising a bed 2 extending laterally, and a spindle structure 3 and a workbench 6 arranged above the bed 2 and capable of cooperating with each other, and the bed 2 is horizontal The entire outer edge of the direction is provided with anti-leakage groove 22.

[0029] The workbench 6 can move horizontally on the bed 2, that is, the Z direction, and the column 4 can move longitudinally on the bed 2, that is, the X direction. At the same time, the column 4 is also equipped with a spindle structure 8 that can be lifted and lowered, that is, moving in the Y d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com