Dual vacuuming device and method for civil aircraft composite repair

A vacuum device and composite material technology, which is applied in the field of double vacuum devices, can solve the problems of inconvenient maintenance, easy air leakage, and long time consumption, and achieve the effects of uniform heating, improved reliability, and improved vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

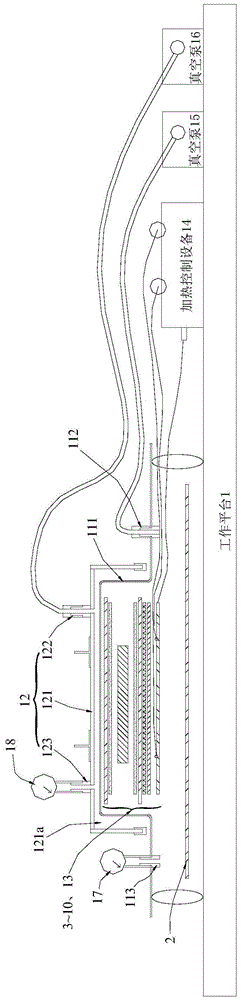

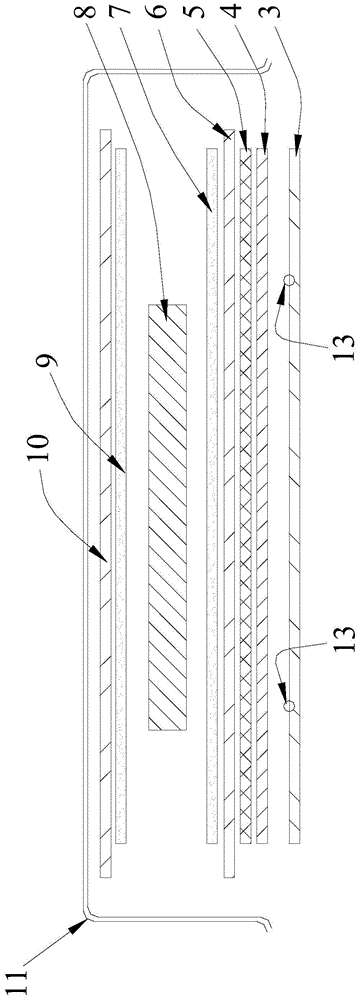

[0038] Such as figure 1 and figure 2 As shown, the double vacuuming device of Embodiment 1 of the present invention can implement a double vacuuming process to the repair patch 8 used for repairing aircraft composite materials, which includes a working platform 1, three layers of air-permeable yarn, an electric blanket 3, and a metal pressing plate 4 , non-porous separation membrane 5, two layers of porous separation membrane, vacuum sealing membrane 11, decompression cover 12, heating control equipment 14 and two vacuum pumps.

[0039] The first air-permeable yarn 2, the electric blanket 3, the metal pressure plate 4, the non-porous separation membrane 5, the second air-permeable yarn 6, the first porous separation membrane 7, the repair patch 8, the second porous separation membrane 9 and the third The air-permeable yarn 10 is laid on the working platform 1 sequentially from bottom to top and forms a raised stack on the working platform 1, wherein the edge of the first air...

Embodiment 2

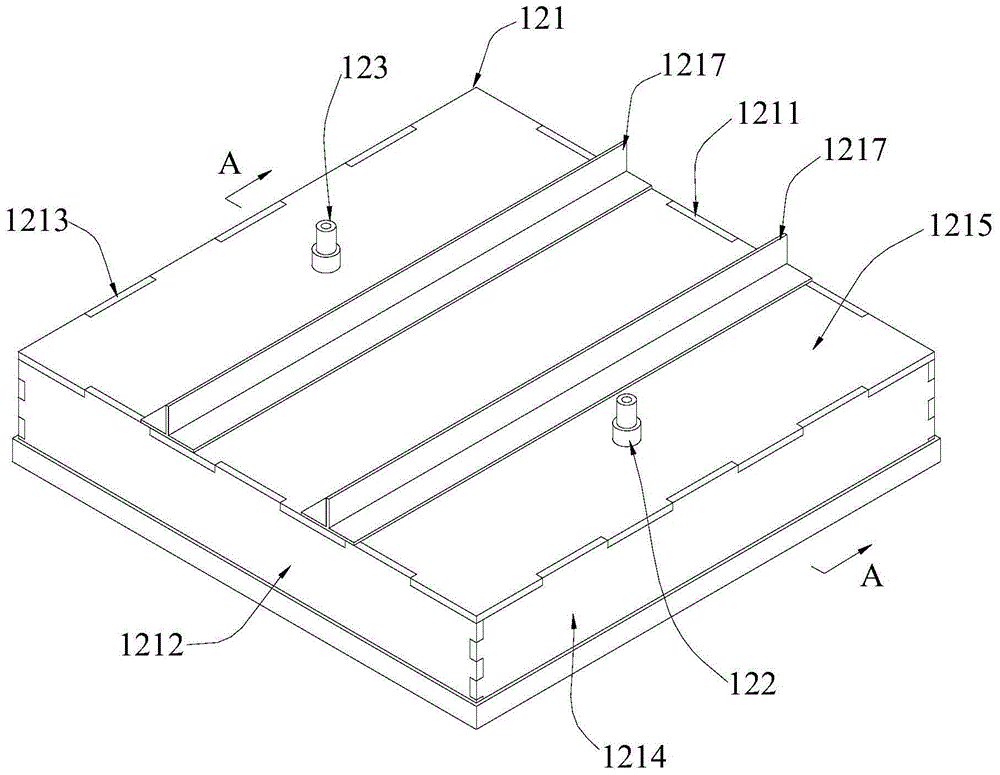

[0054] Such as image 3 and Figure 4 As shown, the double vacuuming device of the second embodiment of the present invention is basically the same as the first embodiment, and their difference is that in the second embodiment, the decompression cover 12 adopts the following preferred structure: the cover body 121 is made of aluminum alloy material, It includes front wall 1211, rear wall 1212, left wall 1213, right wall 1214 and upper wall 1215; front wall 1211, rear wall 1212, left wall 1213, right wall 1214 and upper wall 1215 is connected to form a box with an open bottom, and the inner cavity of the box is the bottom cavity 121 a of the cover body 121 . Among them, L-shaped angle aluminum 1216 is connected to the inner surface of any two connected parts of the front wall plate 1211, rear wall plate 1212, left wall plate 1213, right wall plate 1214 and upper wall plate 1215, and the outer surface of the upper wall plate 1215 is Two or more T-shaped aluminum strips 1217 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com