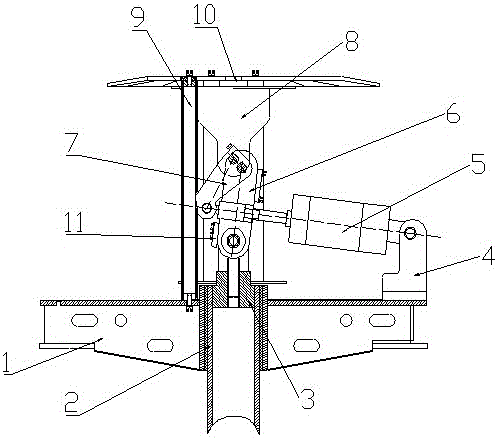

Lifting mechanism of embossing machine

A lifting mechanism and printing machine technology, applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of large volume and high cost, and achieve the effect of overcoming large volume, small environmental pollution, and stable driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] like figure 1 As shown, the present invention discloses a printing machine lifting mechanism, including a lifting frame, a driving mechanism and a frame; the lifting frame includes a lifting frame body 1, a copper sleeve 2 and a fixing block 3; There is a circular through hole in the fixed block 3 and a copper sleeve 2 at the joint joint between the fixed block 3 and a circular threaded through hole in the middle of the fixed block 3; the driving mechanism includes a cylinder 5, a cylinder support seat 4, a lifting rocker 6 and Lifting curved pendulum 7; the lower end of lifting rocker 6 is connected to a threaded column that matches the circular threaded through hole in the fixed block 3, and the upper end is hinged with the upper end of lifting curved pendulum 7; the cylinder support seat 4 is fixed on the lifting frame body 1, The upper end is hinged to one end of the cylinder 5, and the other end of the cylinder 5 is hinged to the lower end of the lifting crank 7; t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap