An energy-saving and environment-friendly lime shaft kiln

An energy saving, environmental protection, lime technology, applied in lime production and other directions, can solve the problems of changing the temperature of the three belts in the kiln, increasing the burning rate, reducing the effective volume of the lime shaft kiln, reducing the power required for transmission, reducing friction consumption, Significant consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

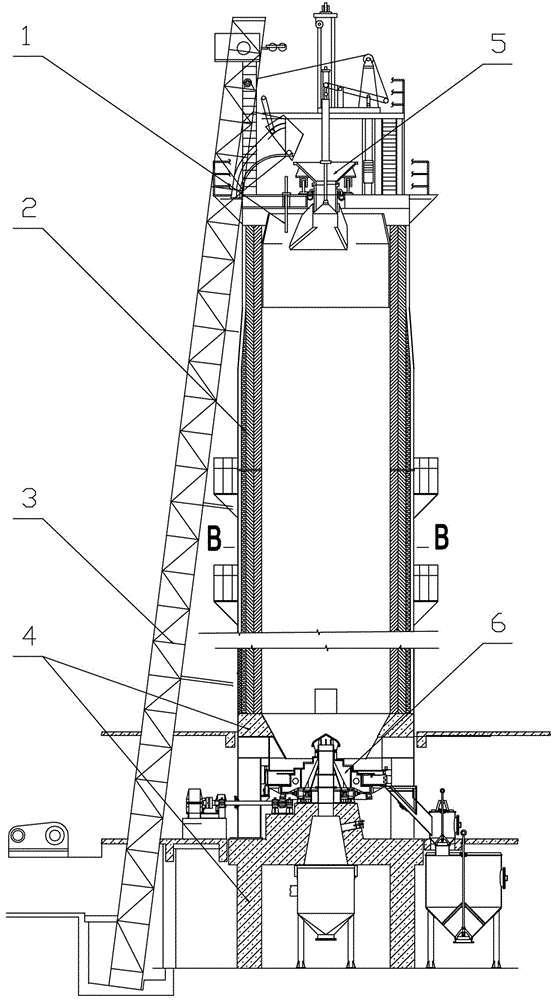

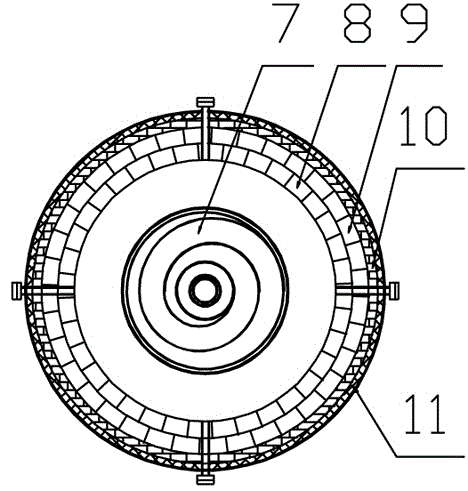

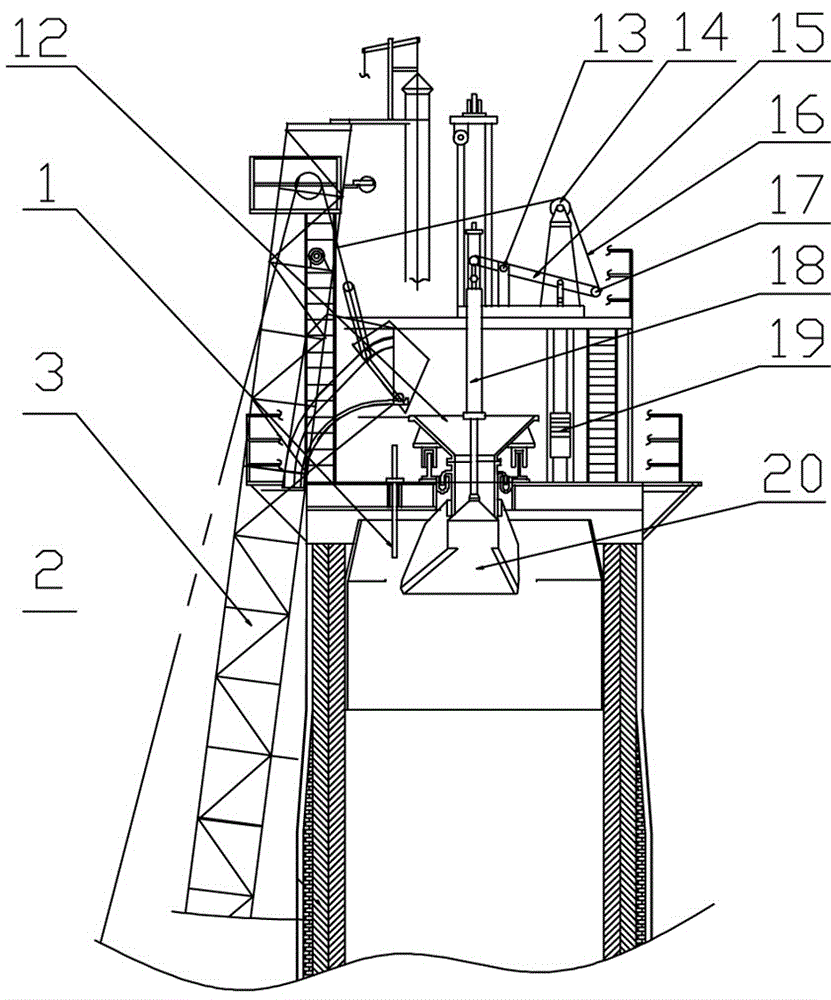

[0037] see Figure 1-Figure 10 , the present invention is an energy-saving and environment-friendly lime shaft kiln, which has a kiln body 2, a feeding device 3 is provided on one side of the kiln body, a material distribution device 5 is provided on the top of the kiln body, and heat-resistant Concrete support platform 4, the bottom of the kiln body is located in the middle of the heat-resistant concrete support platform, and a discharge device 6 is also provided. The discharge device includes a screw cone ash discharge tower 7 arranged at the bottom of the kiln body and located at the center of the heat-resistant concrete support platform , the top of the screw cone ash unloading tower is equipped with a wind cap 33, and the center of the screw cone ash unloading tower is provided with a kiln air inlet channel 32. The bottom spiral ladder is butt-connected with a circle of secondary supporting plates, and the secondary supporting plates are linked with the spiral ladder stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com