Compound oil-displacing agent for high temperature reservoir and compound oil-displacing system

A technology for composite flooding and high temperature oil, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature resistance and cannot be used effectively in oil reservoirs, and achieves delayed demulsification and good solubilization of oil and water. The effect of strong ability to solubilize oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

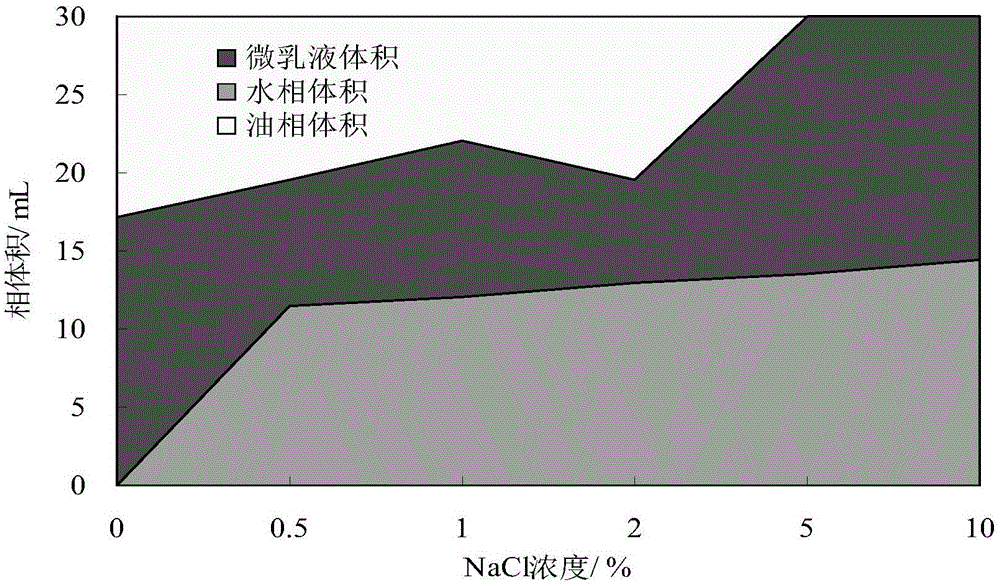

[0037] The composite oil displacement agent of this embodiment is composed of the following components in parts by mass: 10 parts of AN923 type polymer, 80 parts of SH6 type surfactant, and 100 parts of NaCl.

[0038] The composite oil displacement system of this embodiment is composed of components with the following concentrations: 1000 mg / L of AN923 type polymer, 8000 mg / L of SH6 type surfactant, 10000 mg / L of NaCl, and the balance is water.

[0039]The preparation method of the composite oil displacement system of the present embodiment comprises the following steps:

[0040] 1) Take a part of the amount of sewage injected into Shuanghe Oilfield into a beaker, adjust the speed of the blade stirrer to 500r / min, stir to make the water form a vortex, take the amount of granular AN923 polymer, and slowly sprinkle the polymer Pour into water and keep stirring for 2 hours to make polymer mother liquor;

[0041] 2) Take the SH6-type surfactant and NaCl of the formulated amount, ...

Embodiment 2

[0046] The composite oil displacement agent of this embodiment is composed of the following components in parts by mass: 10 parts of AN923 polymer, 100 parts of SH6 surfactant, and 100 parts of NaCl.

[0047] The composite oil displacement system of this embodiment is composed of components with the following concentrations: AN923 polymer 1000 mg / L, SH6 type surfactant 10000 mg / L, NaCl 10000 mg / L, and the balance is water.

[0048] The preparation method of the composite oil displacement system of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0050] The composite oil displacement agent of this embodiment is composed of the following components in parts by mass: 15 parts of AN923 polymer, 50 parts of SH6 surfactant, and 200 parts of NaCl.

[0051] The composite oil displacement system of this embodiment is composed of components with the following concentrations: AN923 polymer 1500 mg / L, SH6 type surfactant 5000 mg / L, NaCl 20000 mg / L, and the balance is water.

[0052] The preparation method of the composite oil displacement system of this embodiment is the same as that of Embodiment 1.

PUM

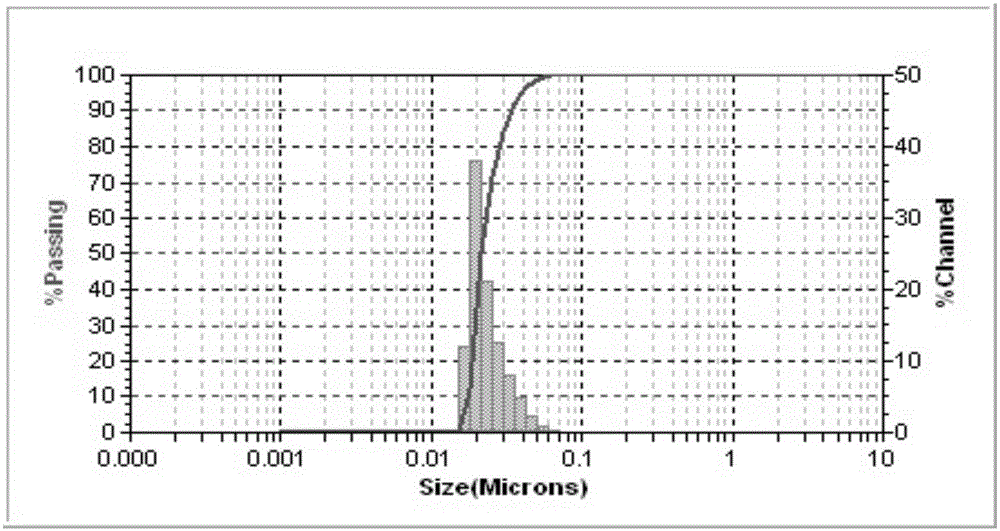

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com