Acoustic panel with unit structure

A unit structure, sound-absorbing panel technology, applied in building components, sound insulation and other directions, can solve the problems of poor sound absorption effect, reduced sound absorption area, large size, etc., to achieve excellent sound absorption performance, improved sound absorption performance, good sound absorption sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

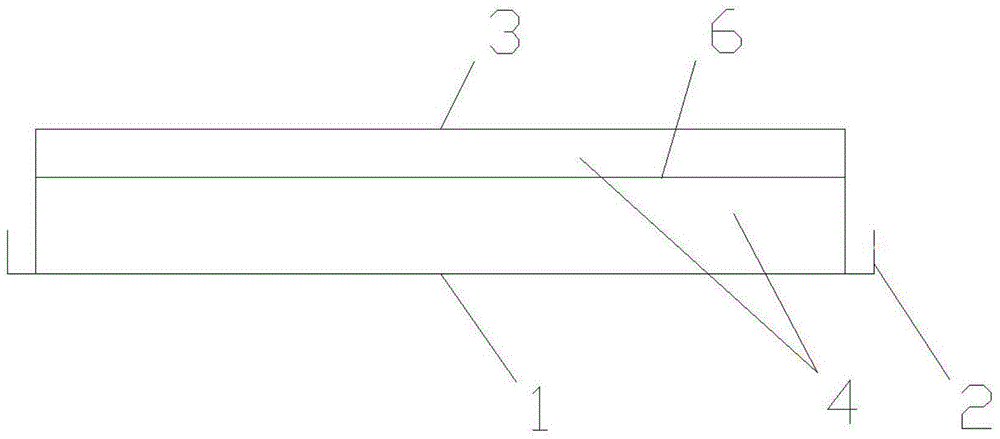

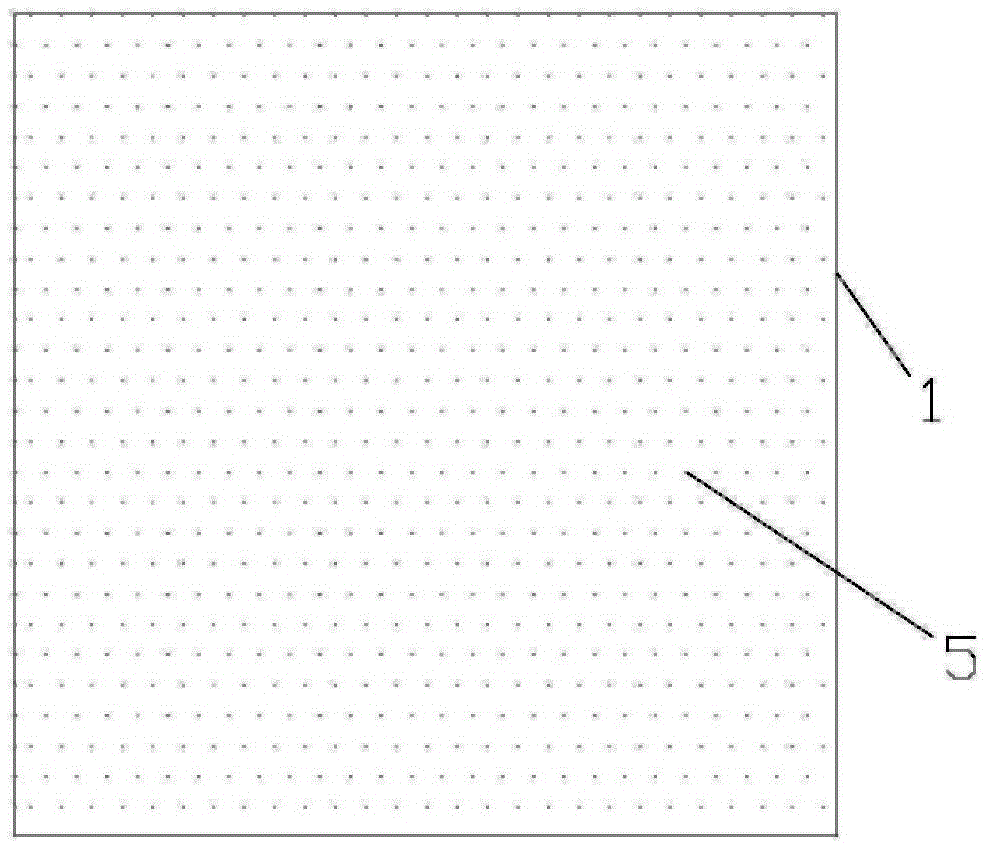

[0036] Embodiment 1: Take the application of the sound-absorbing panel of the unit structure proposed by the present invention in commercial office places as an example, combining figure 1 , image 3 , Figure 4 Be specific. The cross-sectional shape of the sound-absorbing panel of the unit structure of the present invention is as follows: figure 1As shown, the size of the material panel is 600×600mm, the cross-sectional size is 600×90mm, and the height is 90mm; wherein: the material of the ultra-microporous sound-absorbing panel (1) is aluminum alloy with nanospheres (5), The thickness of the ultra-microporous sound-absorbing panel (1) is 0.5mm, and the aperture of the nano-microspheres (5) is 100nm; the aperture of the ultra-microporous sound-absorbing panel (1) is 0.05mm; The face of the ultra-microporous sound-absorbing panel (1) can be pressed to increase the structural strength and sound-absorbing effect, and the figure is star-shaped or flower-shaped; connected with ...

Embodiment 2

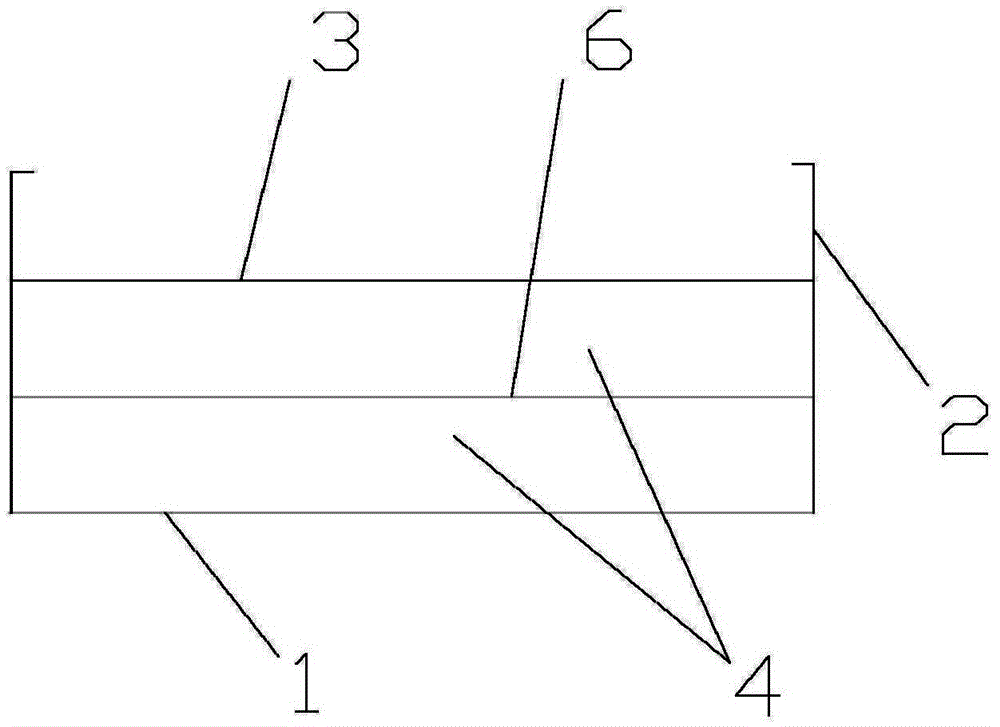

[0037] Embodiment 2: Taking the sound-absorbing panel of the unit structure proposed by the present invention applied to the sound-absorbing purification of the electronic production workshop as an example, combining figure 2 , image 3 and Figure 5 Be specific. The cross-sectional shape of the sound-absorbing panel of the unit structure of the present invention is as follows: figure 1 As shown, its cross-sectional size is 300×60mm, and its length is 4000mm; wherein: the material of the ultra-microporous sound-absorbing panel (1) is aluminum alloy with nano-microspheres (5), and the ultra-microporous sound-absorbing panel ( 1) has a thickness of 1.2mm, and the aperture of the nanosphere (5) is 500nm; the aperture of the ultra-microporous sound-absorbing panel (1) is 0.1mm; and the ultra-micro-porous sound-absorbing panel (1) What is connected is the side panel (2) that can be installed. The side height of the side panel (2) is 60mm, and the side panel (2) is provided with...

Embodiment 3

[0038] Embodiment 3: Taking the sound-absorbing panel of the unit structure proposed by the present invention applied to the sound-absorbing wall and top surface of the railway platform as an example, combining figure 2 , image 3 and Figure 6 Be explained. The cross-sectional shape of the sound-absorbing panel of the unit structure of the present invention is as follows: figure 1 As shown, its cross-sectional size is 300×70mm, and its length is 5000mm; wherein: the material of the ultra-microporous sound-absorbing panel (1) is stainless steel, and the thickness of the ultra-microporous sound-absorbing panel (1) is 0.75mm; The diameter of the ultra-micropores in the microporous sound-absorbing panel (1) is 0.2mm; what is connected with the ultra-microporous sound-absorbing panel (1) is a side plate (2) available for installation, and the side plate (2) The height is 70mm, and the side panel (2) is provided with a folded edge for snap-on keel installation and fixing, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com