High-performance driving device used for fuel injector electromagnetic valve

A driving device and solenoid valve technology, applied in fuel injection devices, machines/engines, charging systems, etc., can solve problems such as large current peak value, long closing and opening time, and increased energy consumption of solenoid valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

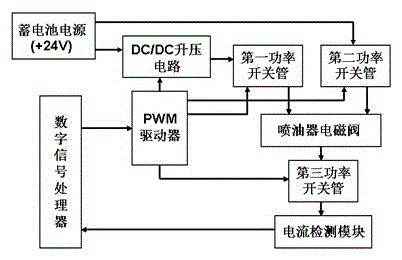

[0017] figure 1 It is a structural block diagram of a high-performance driving device for an injector solenoid valve in an embodiment of the present invention; the driving device is composed of a battery power supply, a DC / DC boost circuit, a digital signal processor, a PWM driver, a power switch tube and a current detection module Composition, the battery power supply is connected to a DC / DC boost circuit, the digital signal processor is connected to a PWM driver and a current detection module, and the PWM driver is connected to a DC / DC boost circuit and a power switch tube respectively, the The power switch tube described above is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com