Echeloned torsion transmission and shock absorbing combined coupling

A coupling and semi-coupling technology, which is applied in the field of connection and transmission of large rotating units, can solve the problems of single function, unit vibration coupling damage, torsional impact unit without coupling, etc., so as to prolong the service life , increase the torsion transmission capacity, and the effect of reasonable matching of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

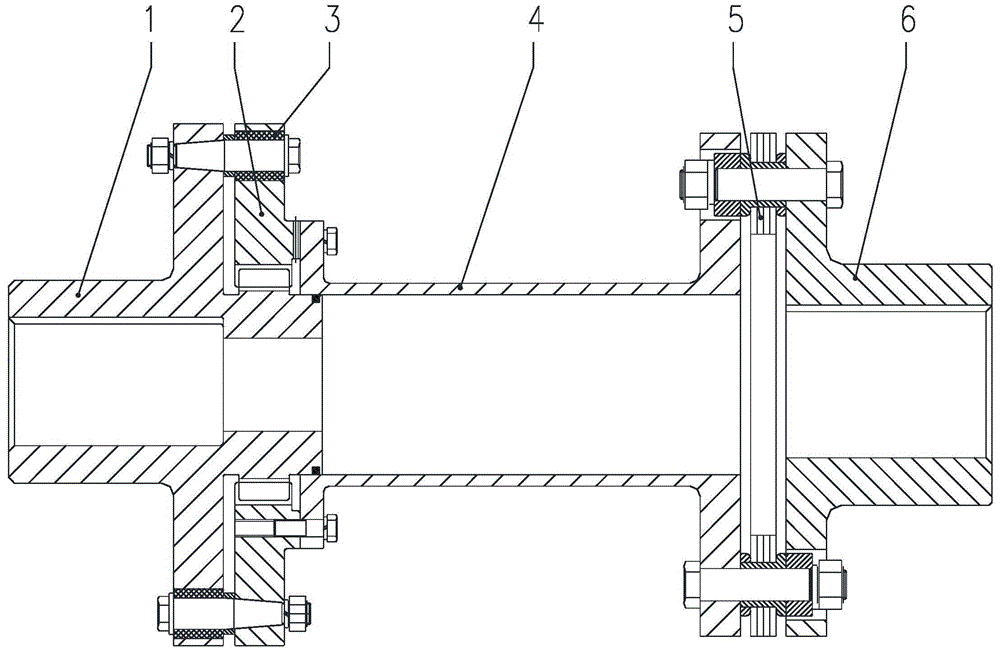

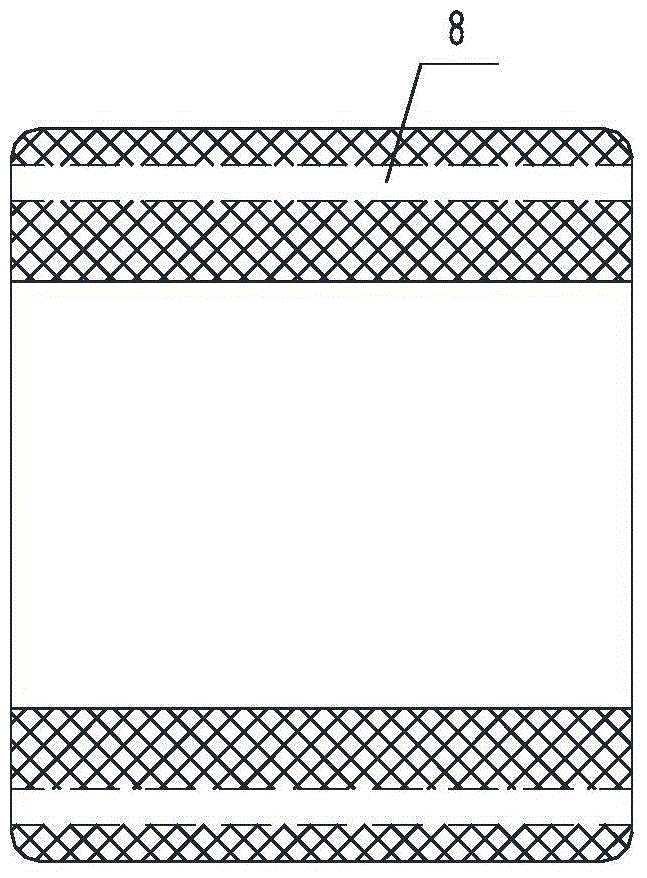

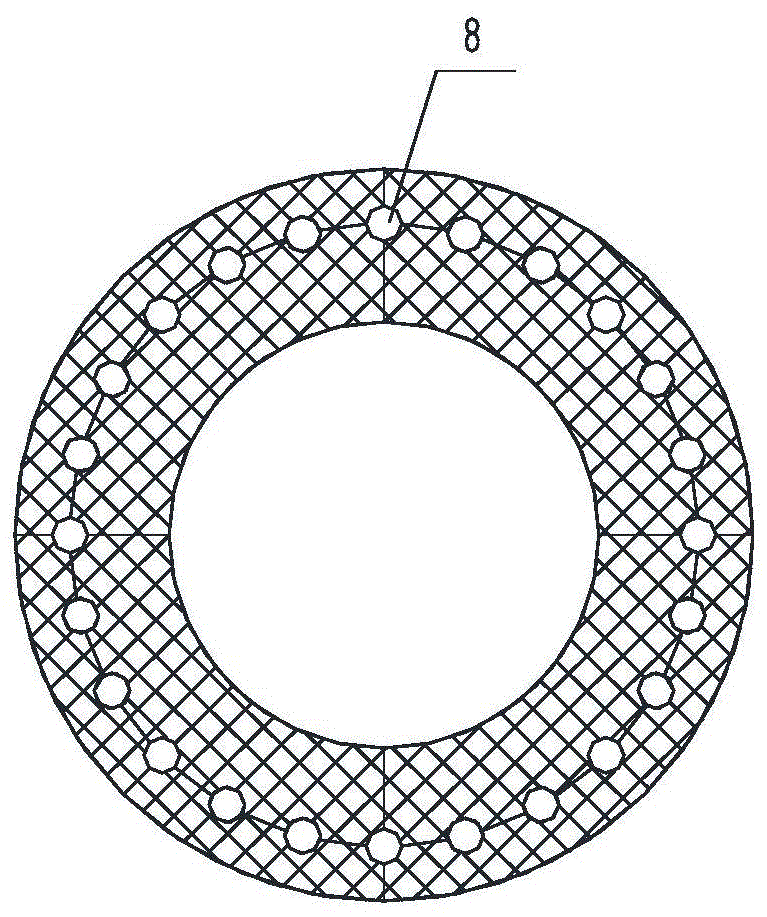

[0036] Such as Figure 1-Figure 4 Shown: the step-by-step torsion transmission and vibration absorption combined coupling, including the input half coupling 1, the sheath 2, the elastic sleeve 3, the middle section 4, the variable stiffness diaphragm group 5 and the output half coupling 6. The flange of the half-coupling 1 at the input end is connected with the sheath 2 through the elastic sleeve 3 to form an elastic torsion transmission and shock absorbing circuit. The outer teeth at the end of the half-coupling 1 at the input end cooperate with the inner teeth of the sheath 2 to form a strengthened torsion transmission circuit. The front end of the intermediate section 4 is connected with the sheath 2, and the rear end is connected with the output half-coupling 6 through the variable stiffness diaphragm group 5 to transmit the torque and further absorb the tip impact of the variable torque. The elastic sleeve 3 adopts a solid hollow structure design, and is provided with co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com