Mechanical decelerator for electrical submersible processing cavity pump

A technology of submersible screw and reducer, which is applied in the direction of mechanical equipment, transmission components, transmission devices, etc., can solve problems such as corrosion and damage, achieve the effects of reducing structural parts, ensuring assembly accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

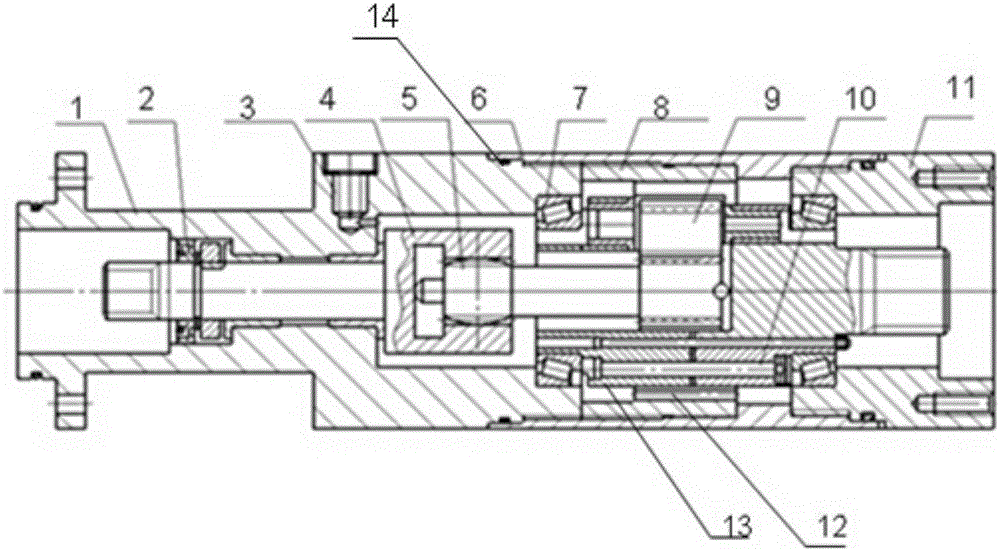

[0017] A mechanical reducer for an electric submersible screw pump, comprising a central shaft 7, a base 1, a casing 6, a planetary wheel 9, a head 11, and a sun gear 5, and the base 1, the casing 6, and the head 11 use column pins 10 Bolt connection, the central shaft 7 is located in the base 1, the housing 6 and the head 11, the oil seal 2 is used to seal between the central shaft 7 and the base 1, the planetary gear 9 is sleeved on the central shaft 7 through the planet carrier, the central shaft 7 and the The sun gear 5 is connected through the high-speed shaft 4, and the base 1 and the high-speed shaft 4 are connected through the oil filling valve 3; in the present invention, the thickness of the housing 6 is 3 mm; and the planet carrier 13 is equipped with a sliding bearing 12; Fix by column pin 10 between frame 13 and planetary wheel 9. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com