Machine vision-guided laser gear chamfering contour measurement apparatus and measurement method thereof

A technology of contour measurement and machine vision, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of the stability of measurement values and the impact of measurement accuracy, and achieve low manufacturing costs, avoid system errors, and improve measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

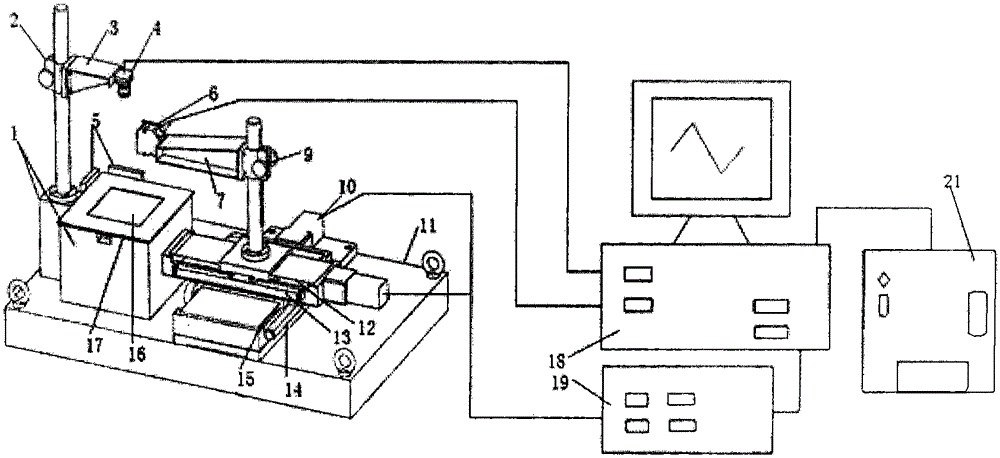

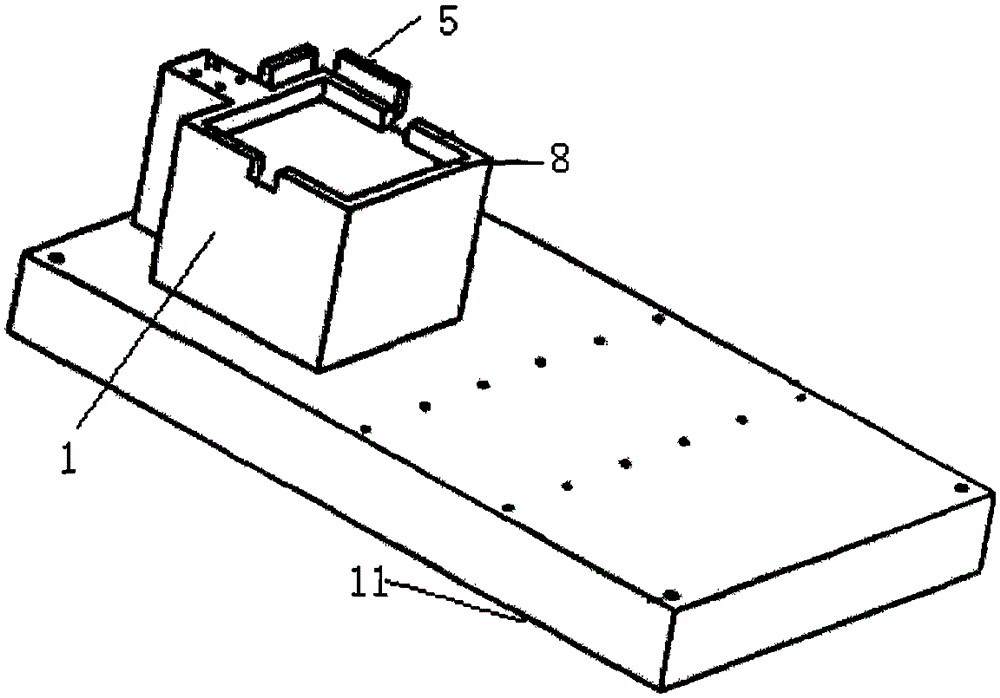

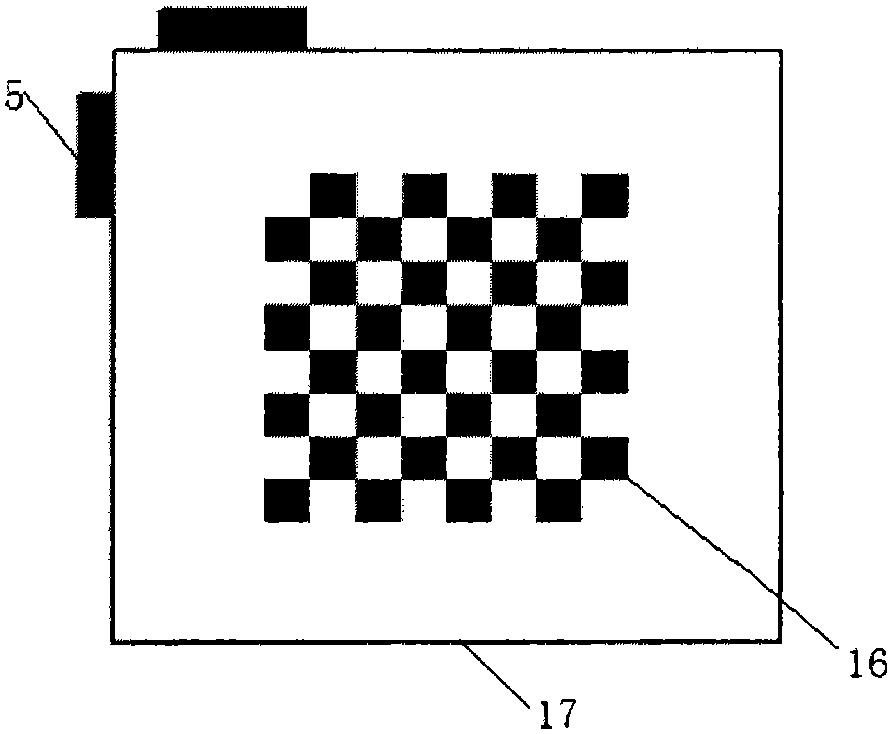

[0050] The invention provides a laser gear chamfer profile measuring instrument based on machine vision and its measurement method. An industrial camera is used to obtain the image of the gear under the backlight, and the position of the gear center is calculated by a calibration algorithm, and measured according to the gear chamfer According to the requirements, the X-Y platform drives the laser displacement sensor to measure the path, and finally carries the laser sensor along the measurement path to complete the contour numerical measurement in the Z direction, and the data is uploaded to the computer, showing the surface contour shape and related parameters of the gear chamfer.

[0051] The main parameters related to the surface profile of the measurable gear chamfer include: the angle of the forming section and its symmetry, the distance from the intersection line of the forming section to the specified surface, the radius of curvature of the arc chamfer, etc.; it has machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com