Equipment for detecting sharp edge and sharp point of edge of textile

A technology for testing equipment and textiles, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., which can solve the problems of cutting users, strong human subjectivity, flocculent burrs or loose edges at suture parts, and avoid edge stabbing , Overcoming subjective misjudgment and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

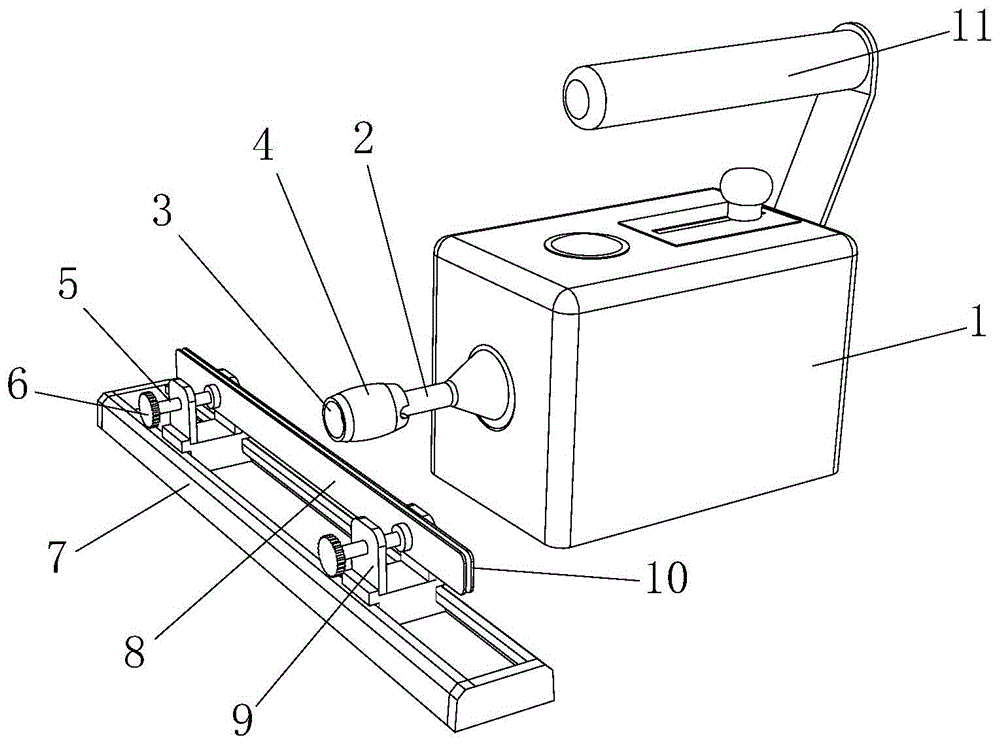

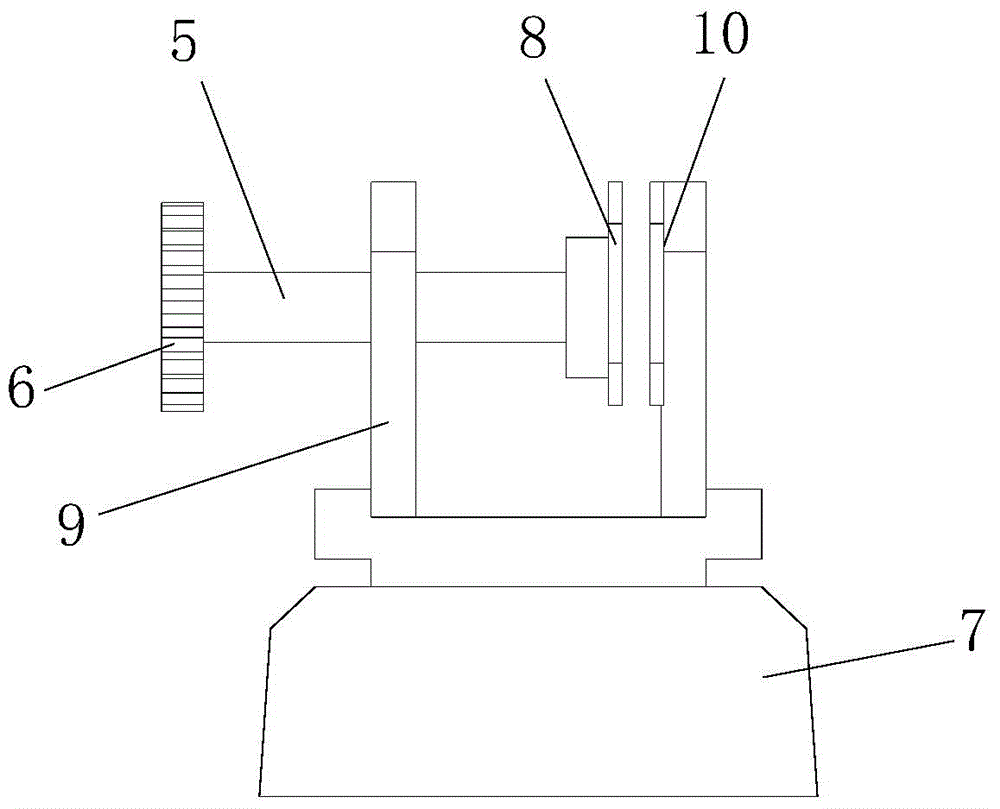

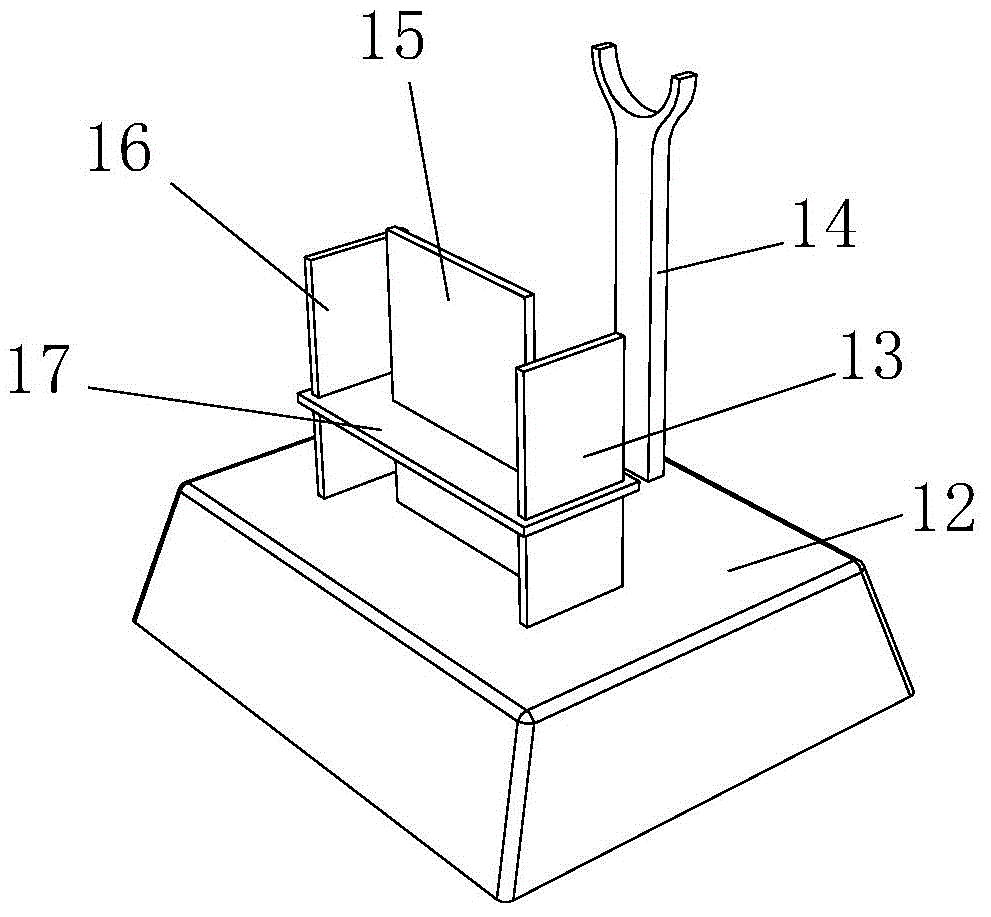

[0026] refer to Figure 1 to Figure 6 , a textile edge sharp edge and sharp point detection equipment, the equipment includes a test instrument 1, a silicone sleeve 3, a single-layer self-adhesive test tape 4 and four parts for clamping the tested textile fixtures.

[0027] Test instruments can be fixed or portable, such as figure 1 , Figure 4 and Figure 6 The portable test instrument shown in , can be provided with a handle 11 for easy transportation. The test instrument has a rotating shaft 2 and an electric mechanism driving it to rotate, and the electric mechanism is an electric motor.

[0028] The silicone bushing 3 is detachably connected with the rotating shaft 2 for carrying the test strip. When measuring, wrap the test tape on the silicone sleeve 3, then install the silicone sleeve 3 on the rotating shaft 2, the rotating shaft 2 rotates, and the test tape contacts the edge of the textile to be tested. After the test is completed, take the Put down the silicone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com