Thermo-optical modulator based on graphene microring structure and manufacturing method thereof

A technology of thermo-optic modulator and manufacturing method, which is applied in the fields of instruments, optics, nonlinear optics, etc., and can solve problems such as limited application, low yield, and complex process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

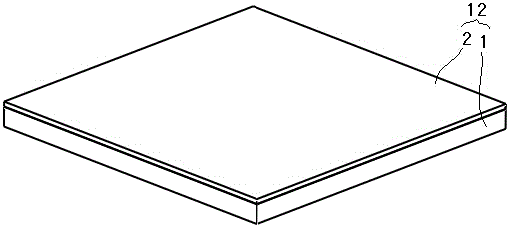

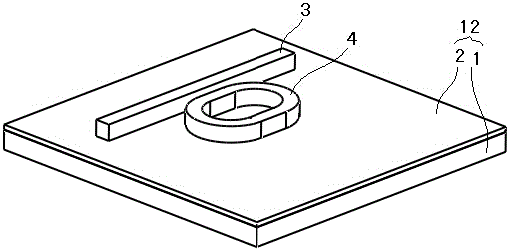

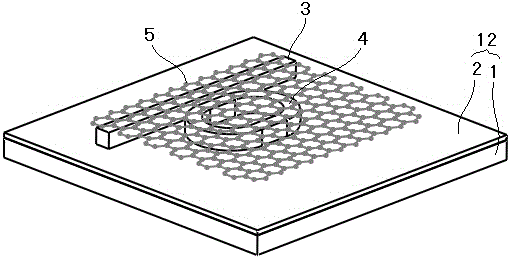

[0027] refer to Figure 4 As shown, the thermo-optic modulator is formed on the silicon-on-insulator substrate 12, the silicon-on-insulator substrate 12 includes a silicon oxide buried oxide layer 1 and a top layer silicon 2 on the silicon oxide buried oxide layer 1, and the top layer silicon 2 is arranged There are a straight waveguide 3 , a ring resonant cavity 4 , a layer of square graphene conductive layer 5 , a first electrode layer 6 , and a second electrode layer 7 . The straight waveguide 3 and the ring resonant cavity 4 are in the same plane, both on the top layer of silicon 2, and there is a small distance between them, about 50-150nm, and there are gratings at both ends of the straight waveguide to couple light into and out of the waveguide ( The grating is not marked in the figure); the graphene conductive layer 5 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com