Automatic staff gauge detection system based on machine vision

An automatic detection and machine vision technology, applied in instruments, computer parts, equipment to reduce ship movement, etc., can solve the problems of high cost, difficult to guarantee the personal safety of staff, poor timeliness, etc. Time-saving and smoother operation, the effect of reducing random errors and human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

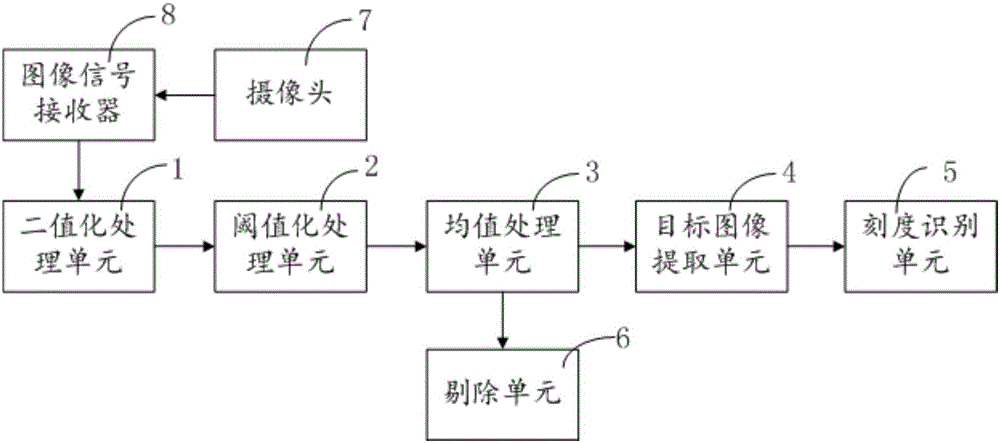

[0022] The embodiment of the present invention provides a water gauge automatic detection system based on machine vision, such as figure 1 , a water gauge automatic detection system based on machine vision, comprising a binarization processing unit 1, a threshold processing unit 2, an average value processing unit 3, a target image extraction unit 4 and a scale recognition unit 5;

[0023] The binarization processing unit 1 is used to extract a plurality of water gauge images from the collected water gauge video images, and perform channel binarization processing on the HIS color space of the water gauge images;

[0024] The thresholding processing unit 2 is configured to perform thresholding processing on the binar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com