Method for Detecting Missing Defects in Embedded SiGe Epitaxy

An embedded silicon germanium and silicon germanium epitaxy technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of CMOS device yield decline, time-consuming, and inability to observe defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

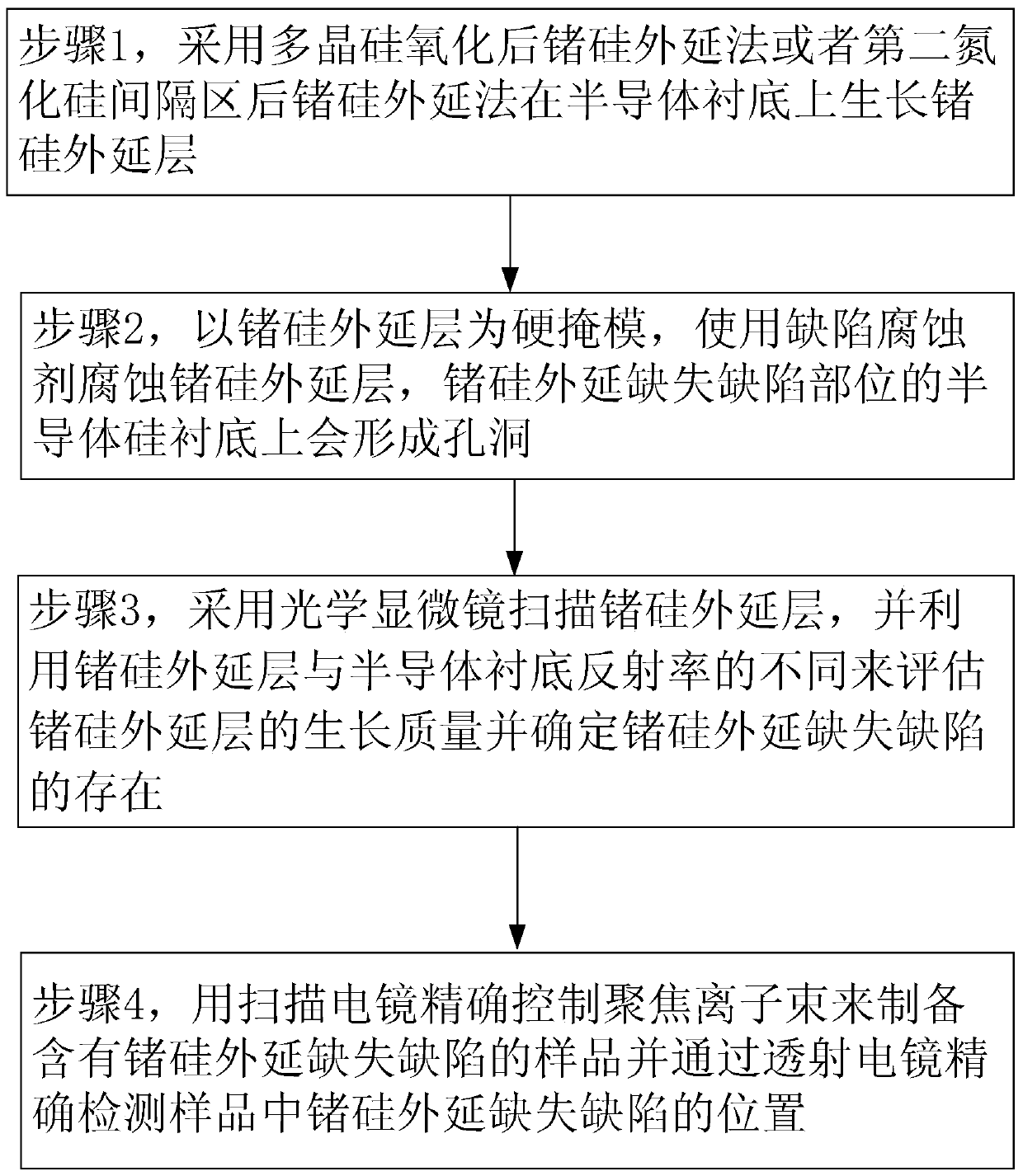

[0025] Such as figure 1 Shown, a kind of method of detection embedded silicon germanium epitaxial missing defect of the present invention comprises the following steps:

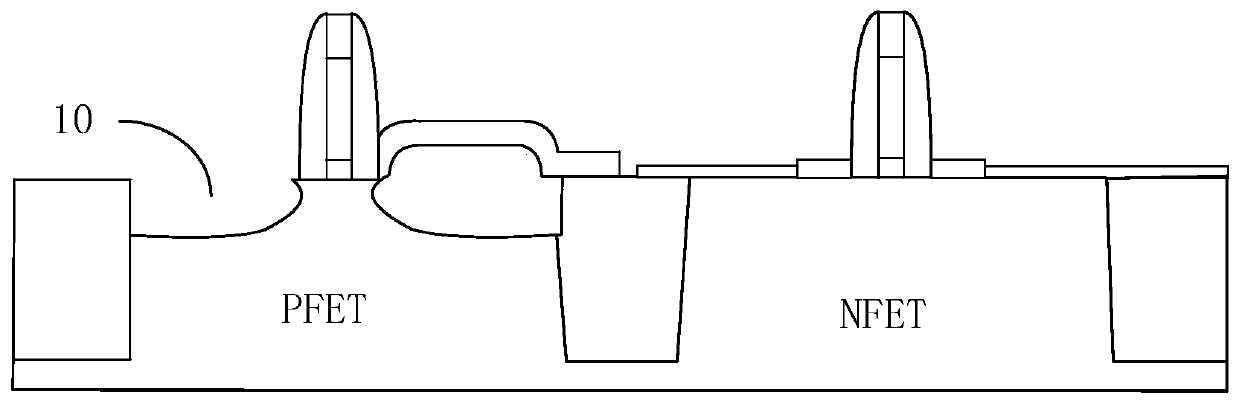

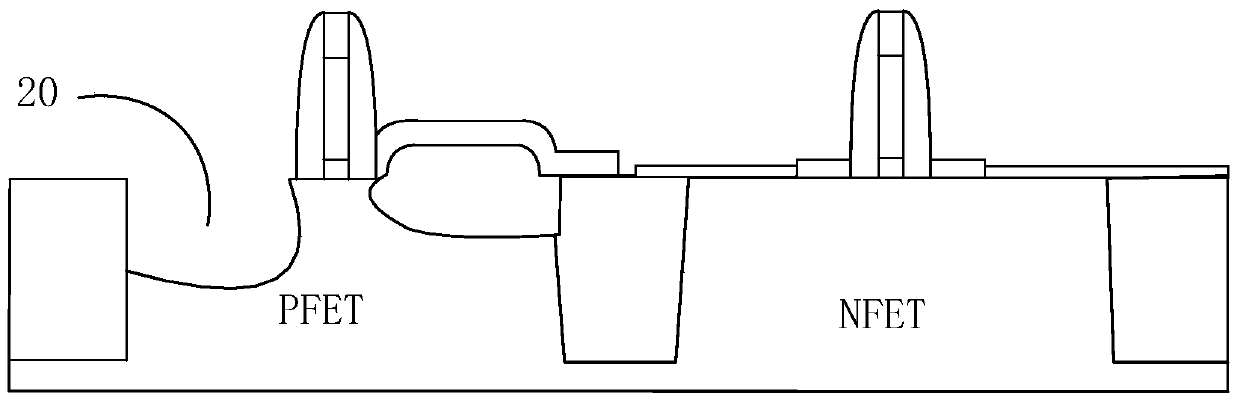

[0026] Step 1, using silicon germanium epitaxy after polysilicon oxidation or silicon germanium epitaxy after the second silicon nitride spacer to grow a silicon germanium epitaxial layer on the semiconductor silicon substrate; preferably, the silicon germanium epitaxial layer has a thickness of 100- 1000 Angstroms. At this time, due to the influence of the embedded SiGe process, some regions on the silicon germanium epitaxial layer may have deletion defects, such as figure 2 There are missing defect sites 10 on the SiGe epitaxial layer shown in .

[0027] Specifically, the silicon germanium epitaxy method after polysilicon oxidation refers to the U-shaped silicon germanium epitaxy process after polysilic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com