Method for manufacturing a fuel tank and fuel tank

A technology of fuel tanks, thermoplastic materials, applied in the direction of arrangement, application, household components combined with the fuel supply of internal combustion engines, capable of solving problems such as mass increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

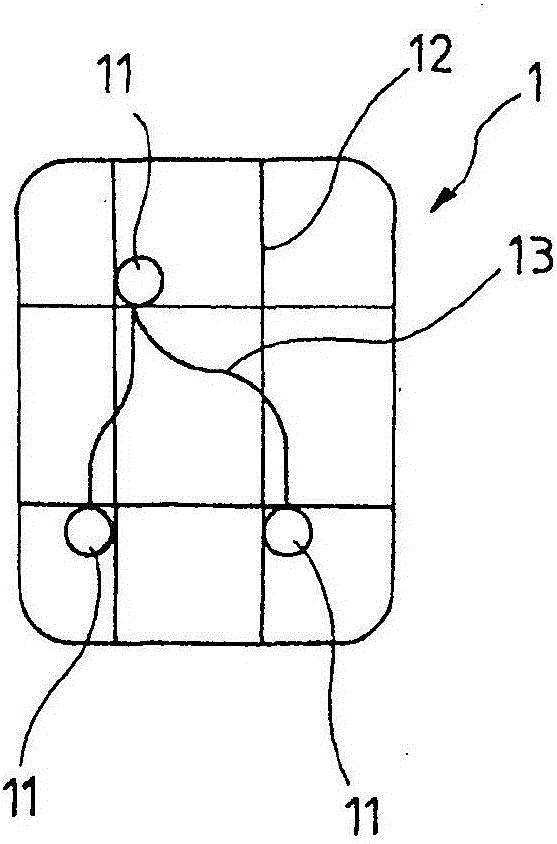

[0041] first refer to attached figure 2 .

[0042] figure 2 A view of the upper casing 1 of the fuel tank according to the invention is shown. The fuel tank is joined together by an upper casing 1 and a lower casing 2 which complements the upper casing, forming a substantially closed hollow casing. A full view of the fuel tank is not shown in the drawings.

[0043] Both the upper shell and the lower shell have a surrounding flange 8 at which the upper shell 1 and the lower shell 2 are connected to form a closed fuel tank.

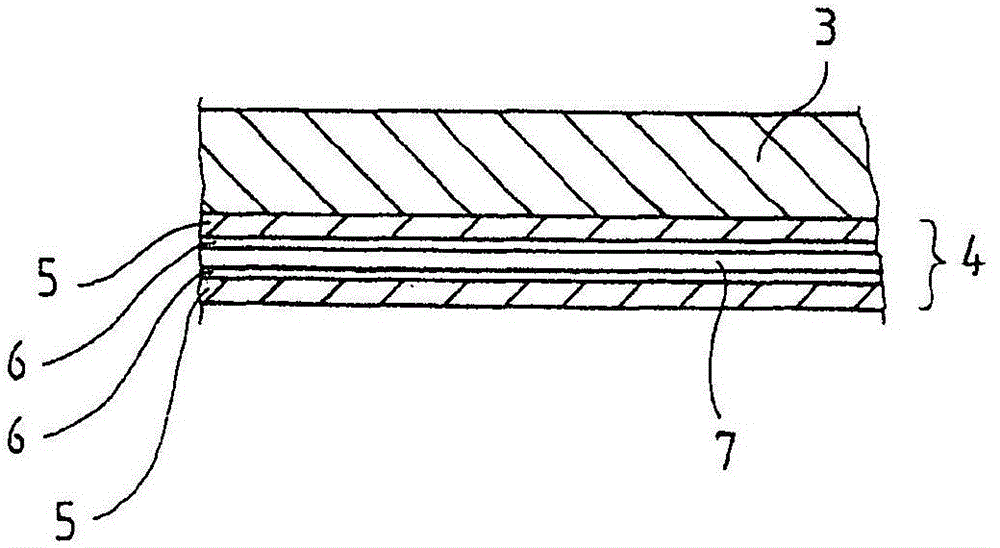

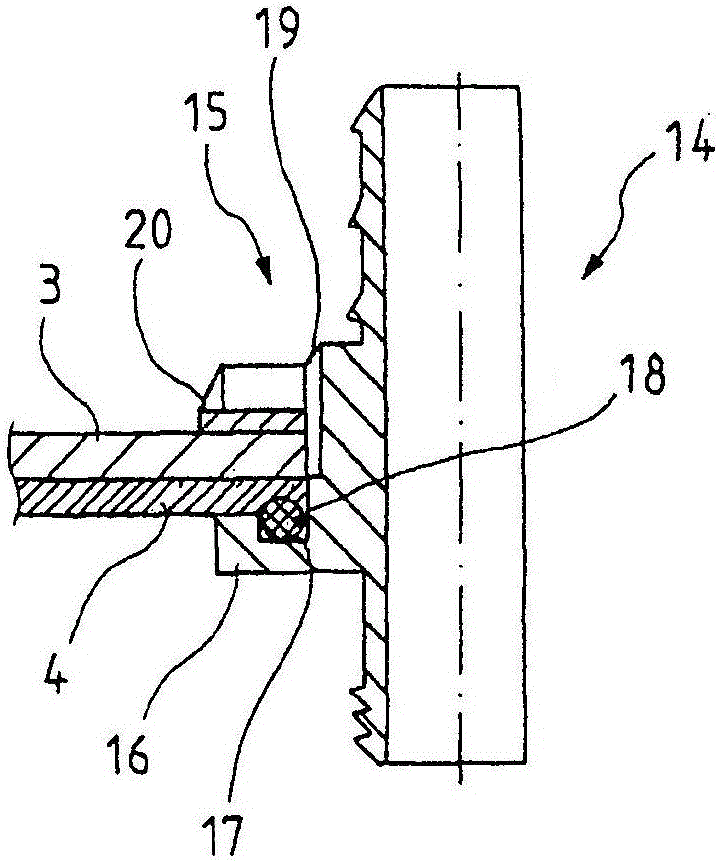

[0044] As stated at the outset, both the upper housing 1 and the lower housing 2 consist of a carrier material in the form of an organometallic sheet 3 and a laminate 4 laminated on one side (in the present case formed as a multilayer film) . The organometallic sheet 3 consists of, for example, an HDPE (high density polyethylene) base material / HDPE (high density polyethylene) base material and has embedded therein fibers in the form of carbon fibers,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com