Yellow braised chicken seasoning and preparation method thereof

A production method and seasoning technology, which is applied in the field of food processing, can solve the problems of long cooking time and difficult standardization of yellow-braised chicken dishes, and achieve the effect of simple production, good stability, and fresh and full taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

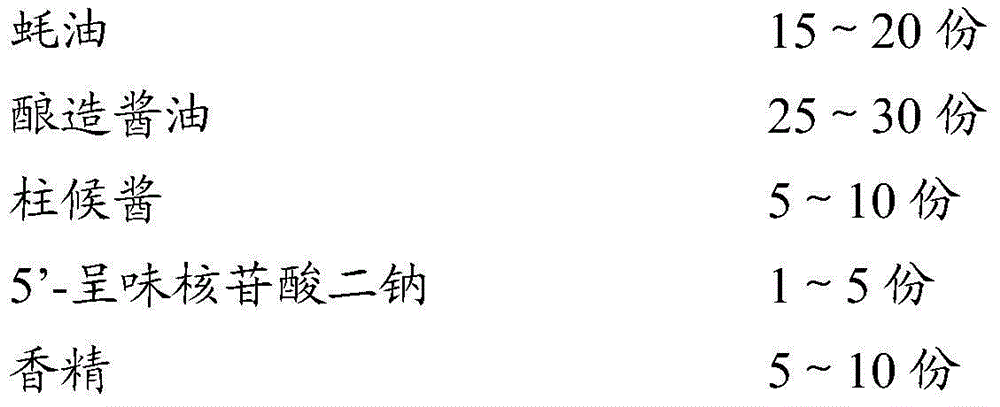

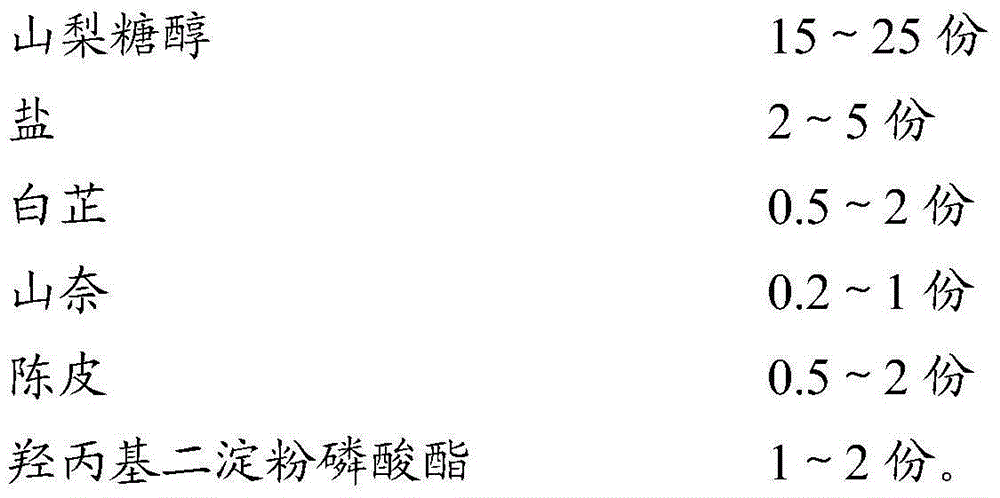

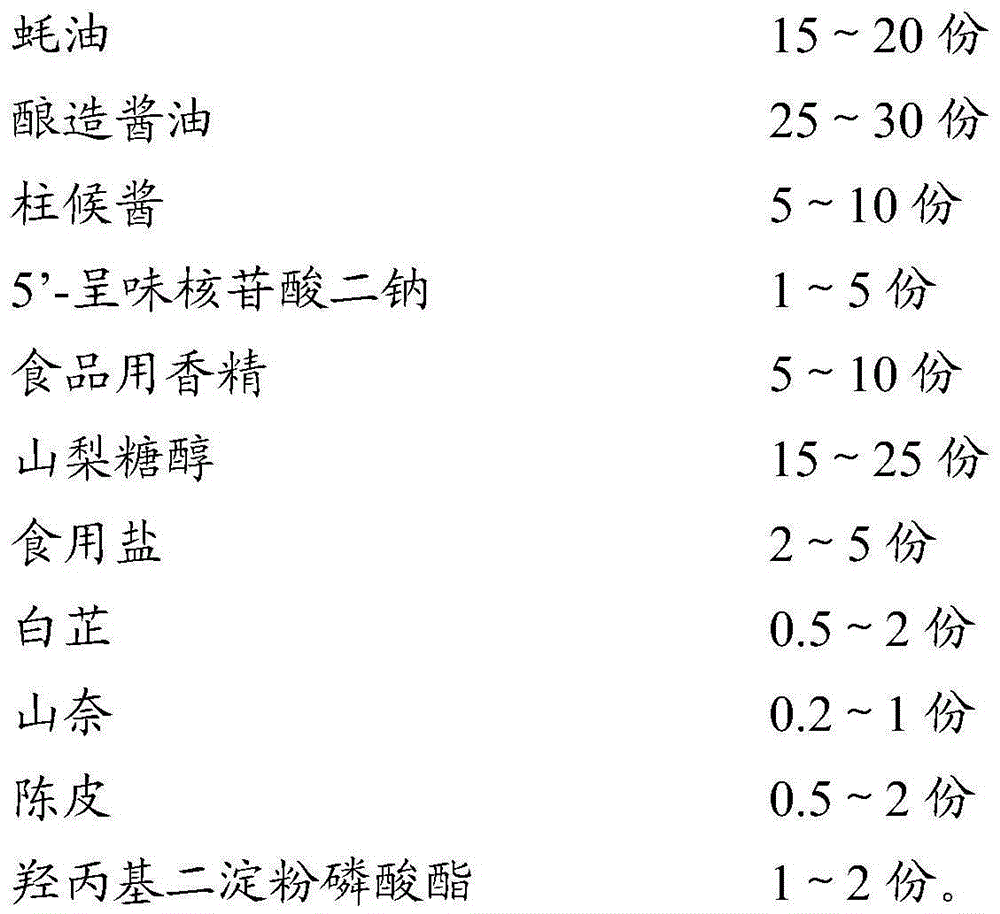

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 screening test

[0036] Table 1 Screening test 1

[0037]

[0038] Screening test 2:

[0039] Stirring at 85°C for 15 minutes, then cooling down to 60°C to prepare the seasoning sauce, and then make it into finished dishes, taste and evaluate by a 10-person evaluation team, and record the average value as the evaluation result. A single factor 8-level test was carried out on a single raw material in order to screen the optimal range of raw material components.

[0040] Table 2 Screening Test 2

[0041] Raw material optimization single factor 8 level test data

[0042]

[0043]

[0044] Table 3 Screening test 3

[0045]

Embodiment 2

[0046] The preparation of embodiment 2 braised chicken seasoning

[0047] Mix 15 parts of oyster sauce, 30 parts of brewed soy sauce, 9 parts of Zhuhou sauce, 1 part of 5`-flavored nucleotide disodium, 5 parts of food flavor, 25 parts of sorbitol, 2.5 parts of edible salt, and 1.3 parts of Angelica dahurica powder , 0.2 parts of kaempferen powder, 1.2 parts of tangerine peel, 1 part of hydroxypropyl distarch phosphate, etc., weighed and mixed according to the first liquid and then the solid, heated to 85 ° C in a thermal reaction kettle, stirred at a constant speed for 15 minutes, stopped heating, and cooled to 55-60 ℃, can be packaged.

Embodiment 3

[0048] The preparation of embodiment 3 braised chicken seasoning

[0049] Mix 20 parts of oyster sauce, 25 parts of brewed soy sauce, 7 parts of Zhuhou sauce, 5 parts of 5'-flavored nucleotide disodium, 7 parts of food flavor, 22 parts of sorbitol, 4 parts of edible salt, and 1.5 parts of angelica powder , 0.8 parts of kaempferen powder, 0.5 parts of tangerine peel, 1.4 parts of hydroxypropyl distarch phosphate, etc., weighed and mixed according to the first liquid and then the solid, heated to 85 ° C in a thermal reaction kettle, stirred at a constant speed for 15 minutes, stopped heating, and cooled to 55-60 ℃, can be packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com