Braised chicken and manufacturing method thereof

A production method and technology of stewed chicken, which is applied in the field of food processing, can solve the problems of uneven quality of stewed chicken products and restrict the development of stewed chicken, and achieve the effects of broadening the consumer market, uniform color and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The making of embodiment 1 yellow stewed chicken of the present invention

[0037] Craftsmanship:

[0038] (1) Marinating of bone-in chicken legs: thaw frozen chicken legs at 4°C, cut into pieces, add marinade per kilogram of chicken legs: 0.8g turmeric, 20g salt, 15g white wine, 1g pepper, marinate at 4°C for 3 hours.

[0039] (2) Frying and coloring: oil-to-plant ratio 2:1, soybean oil 160°C, fry for 3 minutes, remove and drain the oil, and store in refrigerator.

[0040] (3) Preparation of stewing soup: Calculated per kilogram of bone-in chicken thigh meat, 35g of soybean oil, keep at 120°C for 1min, add 2g of rock sugar, 3g of ginger slices, 1g of star anise, keep for 20s, continue to add 500g of water, dried chili 3g, shiitake mushrooms 8g, soybean paste 25g, dark soy sauce 30g, pepper oil 5g, fresh chicken juice 15g, cooking wine 10g, sesame oil 5g, after boiling, keep on low heat for 20min.

[0041] (4) Preparation of braised chicken nuggets and soup packets: C...

Embodiment 2

[0045] The making of embodiment 2 yellow stewed chicken of the present invention

[0046] Craftsmanship:

[0047](1) Marinate chicken legs with bone: thaw frozen chicken legs at 4°C, cut into pieces, add marinade per kilogram of chicken legs: 1.8g turmeric, 35g salt, 25g white wine, 2g peppercorns, marinate at 4°C for 5 hours.

[0048] (2) Frying and coloring: oil-to-plant ratio 2:1, corn oil at 180°C, fry for 2 minutes, remove and drain the oil and store in refrigerator.

[0049] (3) Preparation of stewing soup: Calculated per kilogram of bone-in chicken thigh meat, corn oil 50g, keep at 120°C for 1min, add rock sugar 5g, ginger slices 6g, star anise 3g, keep for 40s, continue to add 800g of water, dried chili 6g, 15g shiitake mushrooms, 40g soybean paste, 50g dark soy sauce, 10g prickly ash oil, 30g fresh chicken juice, 20g cooking wine, 12g sesame oil, after boiling, keep it on low heat for 40min.

[0050] (4) Preparation of braised chicken nuggets and soup packets: Calcu...

Embodiment 3

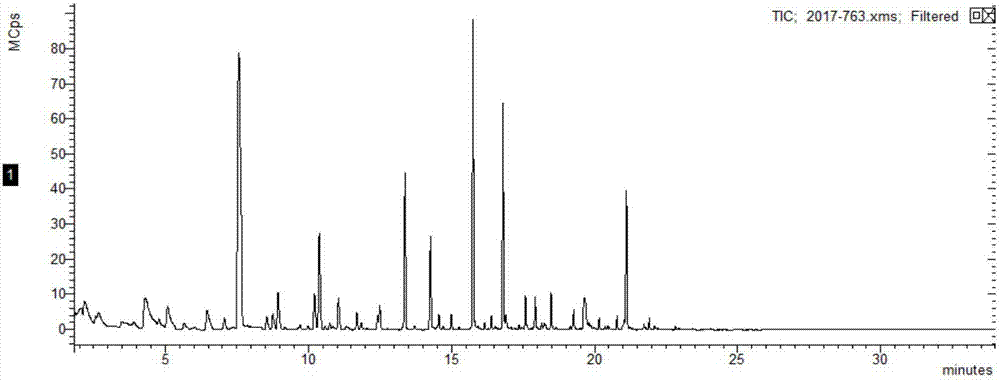

[0065] Embodiment 3 product volatile flavor analysis

[0066] The flavor components were extracted by static headspace solid-phase microextraction (SPME).

[0067] Extraction method: (1) Weigh 6.0 g of the braised chicken nuggets prepared in Example 1 of the present invention and put it into a 15 mL headspace bottle, and seal the cap immediately. Insert the CAR / PDMS extraction head aged at 270°C for 1 hour into the headspace of the sample bottle, and absorb at 50°C for 30 minutes. The extracted extraction head after adsorption was taken out and inserted into the gas chromatography inlet, desorbed at 250°C for 3 minutes, and started the instrument to collect data at the same time.

[0068] (2) DB-wax quartz capillary column (column length 30m, inner diameter 0.25mm, film thickness 0.25μm), carrier gas is helium, injection port temperature is 250°C, column flow rate is 0.8mL·min -1 , a three-stage temperature program was adopted, the initial temperature was 40°C and kept for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com