Organic waste gas purification process

A technology of organic waste gas and purification process, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc. It can solve the problems of unstable reaction effect of activated carbon, low efficiency of waste gas treatment, high operating cost and other problems, and achieve the treatment effect Thoroughness, stable treatment effect, and low investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

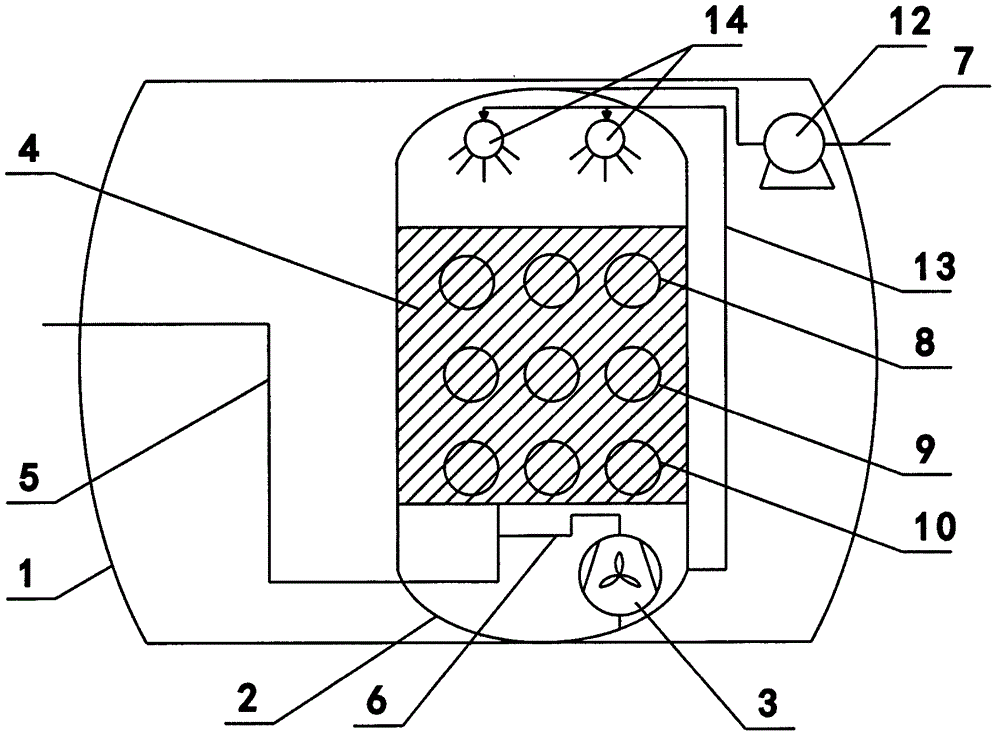

[0025] As an embodiment of the organic waste gas integrated purification equipment of the present invention, such as figure 1 As shown, it is used to purify organic waste gas. The organic waste gas integrated purification equipment includes a housing 1, a reaction vessel 2, a free radical generation system 3, a reaction wall 4 and a reaction liquid atomization system. The housing 1 is a closed The free radical generating system 3 and the reaction wall 4 are arranged inside the reaction vessel 2, the reaction wall 4 is located above the free radical generating system 3, the reaction vessel 2 is arranged inside the housing 1, and the organic waste gas Input the interior of reaction vessel 2 through input pipeline 5, described free radical generating system 3 is connected with described input pipeline 5 through communication pipeline 6, is provided with catalyst on described reaction wall 4, and described reaction liquid atomization system is arranged at the Above the reaction wa...

Embodiment 2

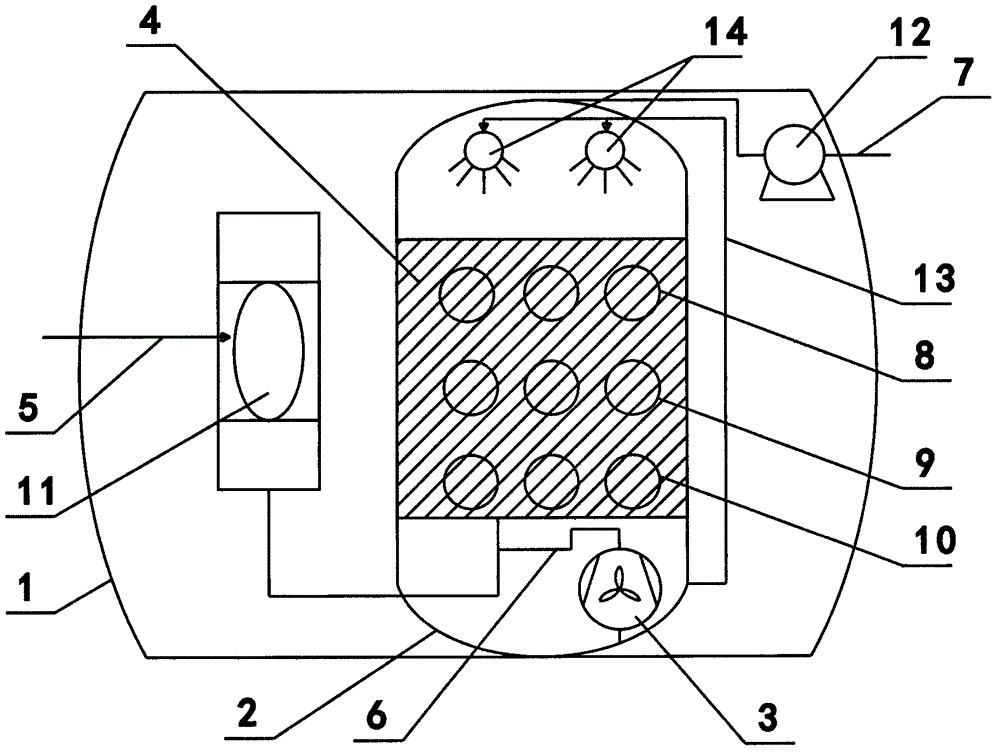

[0037] As an embodiment of the organic waste gas integrated purification equipment of the present invention, such as figure 2 As shown, the difference from Embodiment 1 is that in this embodiment, a filter system 11 is provided on the input pipe 5 , and the filter system 11 is located outside the reaction vessel 2 . Before the step (1), there is an operation of filtering the organic waste gas entering the housing 1 using the filter system 11 , and the filtered organic waste gas then enters the reaction vessel 2 . The catalyst is titanium oxide. The catalyst carrier is silica gel and ceria. When the organic waste gas contains more particulate pollutants, a filter system 11 is required, and the filter system 11 can remove particulate pollutants in the organic waste gas.

[0038] In this embodiment, other structures, technological processes and beneficial effects are consistent with those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0040] As an embodiment of the organic waste gas integrated purification equipment of the present invention, the difference from Embodiment 1 is that in this embodiment, the input pipeline 5 is provided with a filter system 11, and the filter system 11 is located in the reaction vessel 2 external. Before the step (1), there is an operation of filtering the organic waste gas entering the housing 1 using the filter system 11 , and the filtered organic waste gas then enters the reaction vessel 2 . The catalysts are iron oxides and manganese oxides. The catalyst carrier is activated carbon.

[0041] In this embodiment, other structures, technological processes and beneficial effects are consistent with those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com