Wear-resistant tooth roller of tooth roller crusher and production method of wear-resistant tooth roller

A manufacturing method, crusher technology, applied in grain processing, etc., can solve the problems of wear-resistant layer falling off, high cost, uneconomical, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

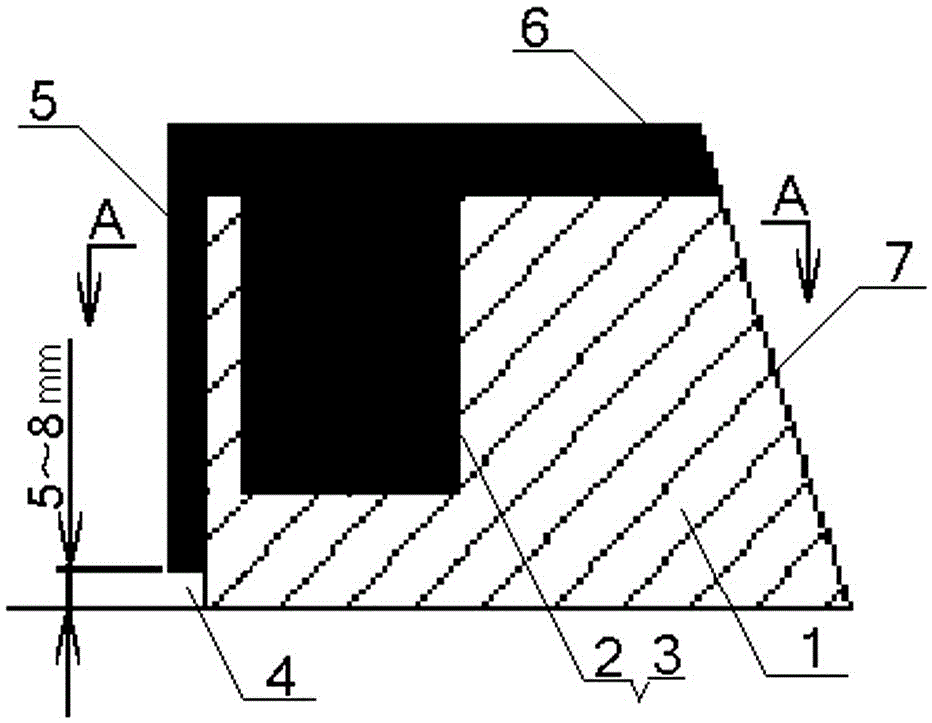

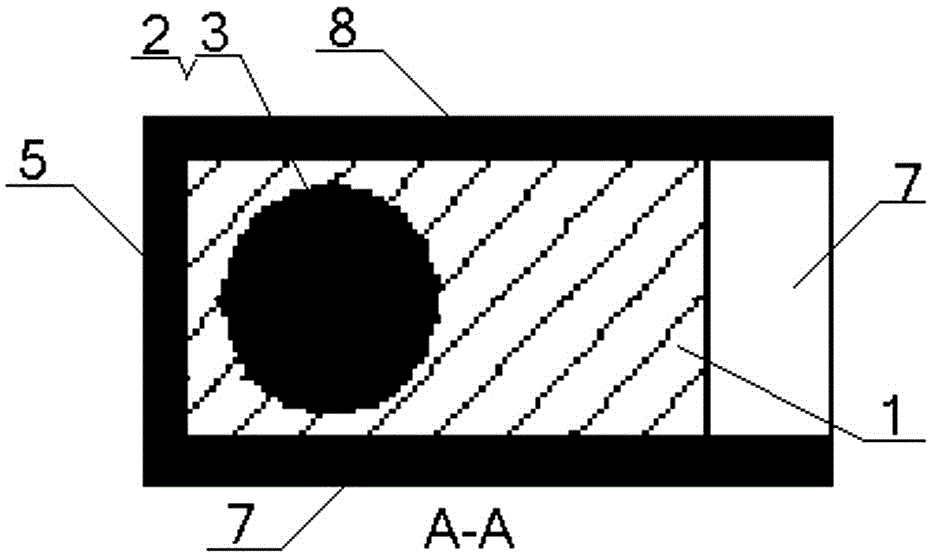

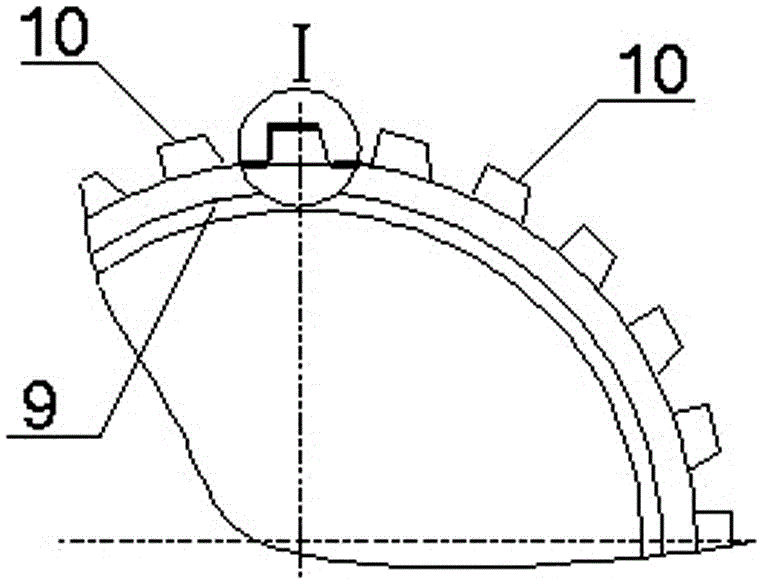

[0029] Below structure accompanying drawing, the present invention is described further.

[0030] In order to achieve the purpose, the applicant has developed a brand-new toothed roll manufacturing method through careful and scientific analysis of the structure and working principle of the existing toothed roll crusher, and adopts a step-by-step method to manufacture new toothed rolls. The toothed roller does not have teeth, the manufacturing process of the roller mold is greatly simplified, the casting process is also simplified, and the quality of the roller is also greatly improved. According to the requirements of the drawing of the roller, the roller blank without teeth is cast, and the inner and outer surfaces are left with sufficient machining allowance, about 10mm, to ensure that the required precision can be achieved after two times of processing. In order to ensure the outer roundness of the roller and facilitate the welding of the roller teeth, the rough machining o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com