Numerical control liner guide rail trench grinding device

A linear guide rail and grinding technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, abrasive surface adjustment device, etc., can solve the problems of not being able to match and fully meet the needs of the market, and achieve a small number, Easy adjustment and maintenance, low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

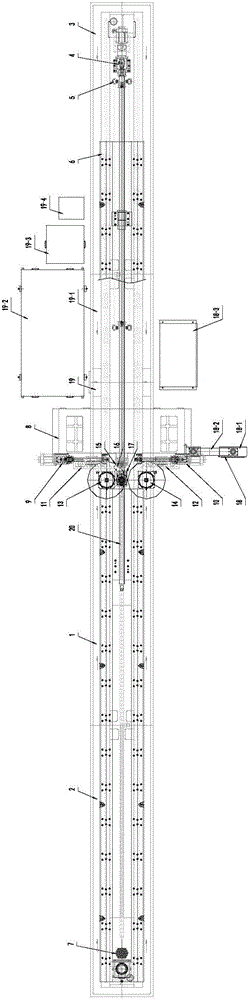

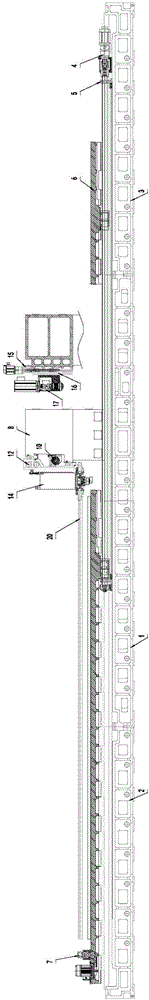

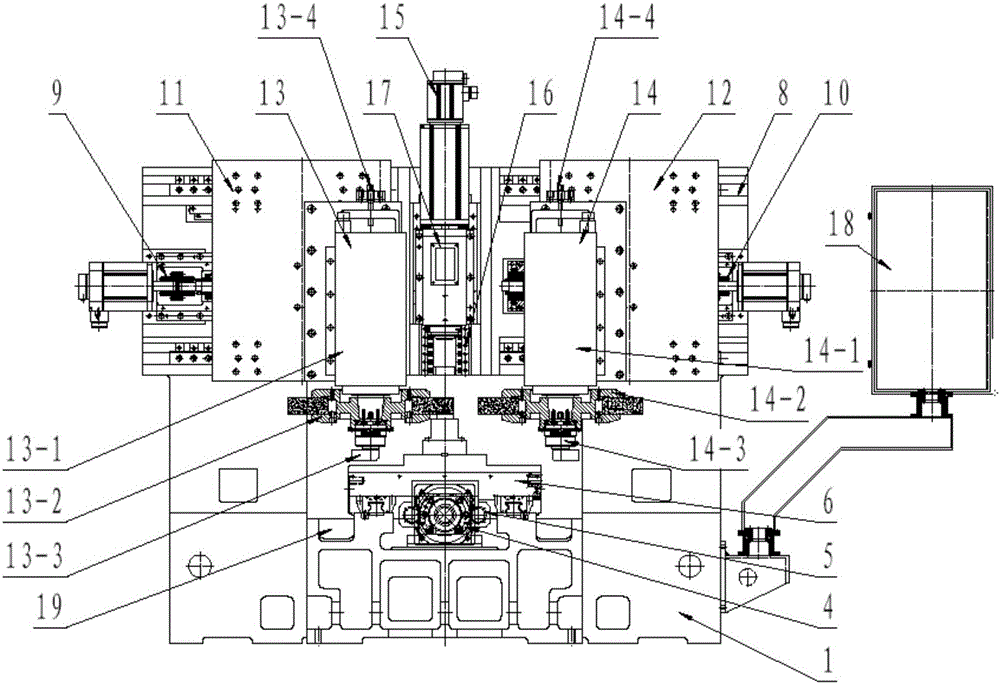

[0036] see figure 1 and figure 2 , the CNC linear guideway groove grinding device provided by the present invention mainly includes a main bed 1, a left auxiliary bed 2, a right auxiliary bed 3, an X-axis feed mechanism 4, an X-axis screw auxiliary support mechanism 5, X-axis workbench carriage 6, diamond roller dresser 7, gantry-type column beam 8, Y-axis left feed mechanism 9, Y-axis right feed mechanism 10, Y-axis left grinding wheel carriage 11, Y-axis right grinding wheel carriage 12. Y-axis left grinding wheel spindle 13, Y-axis right grinding wheel spindle 14, Z-axis feed mechanism 15, Z-axis carriage 16, Z-axis multifunctional spindle 17, operation control system 18 and cooling circulation system 19.

[0037] The operation control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com