Four-degree-of freedom piezoelectric micro-clamp

A micro-clamp, degree-of-freedom technology, applied in the direction of chucks, circuits, relays, etc., can solve the problems of increased complexity, design difficulty and cost of micro-assembly and micro-operating system, and reduce the design difficulty and complexity. , the effect of reducing mass and volume, reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

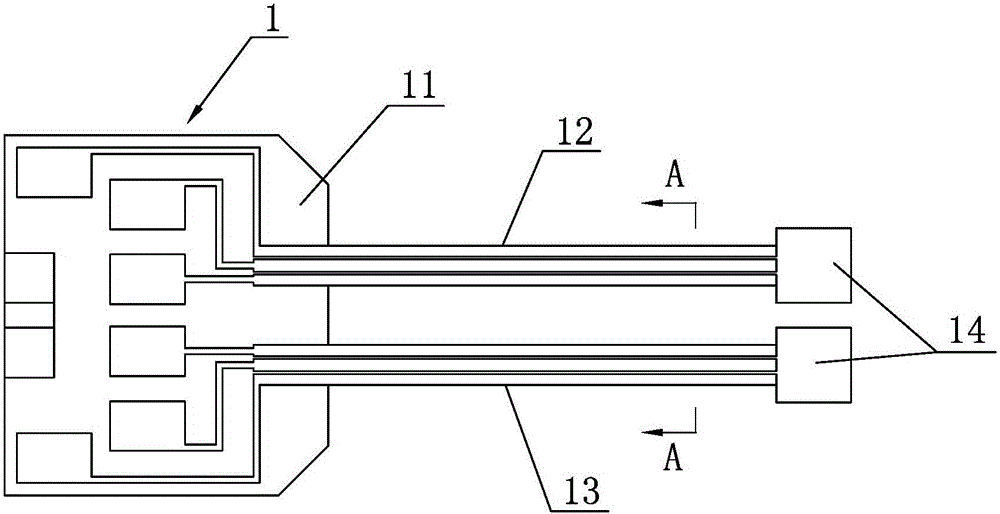

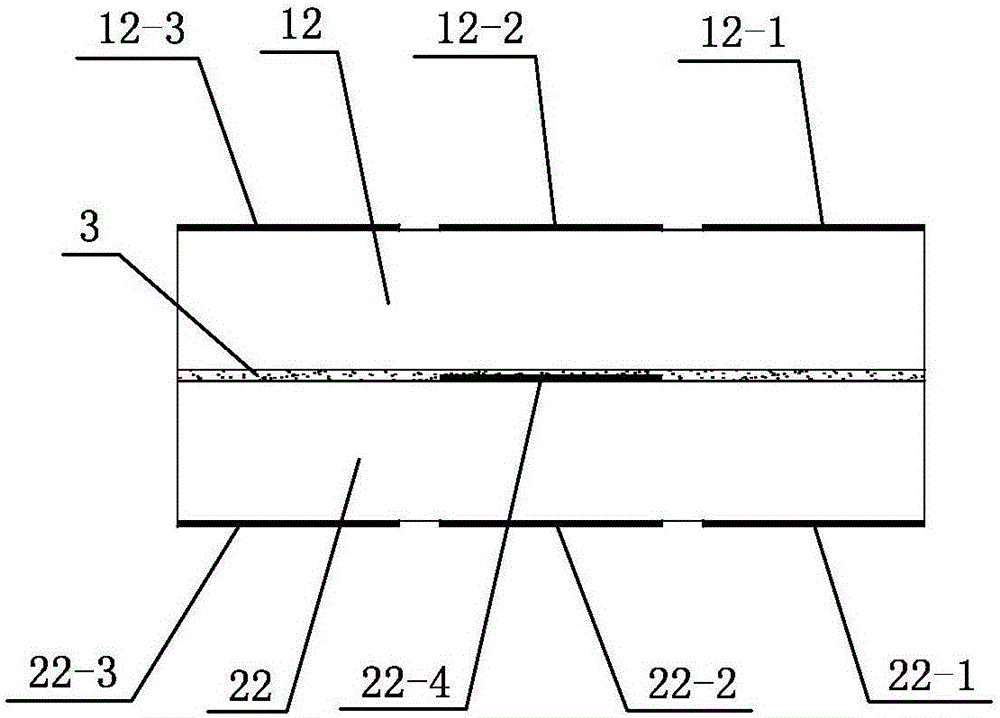

[0020]Embodiment 1: As shown in the figure, a four-degree-of-freedom piezoelectric micro-clamp includes an upper piezoelectric ceramic wafer 1 and a lower piezoelectric ceramic wafer 2, and the bonding surface of the upper piezoelectric ceramic wafer 1 and the lower piezoelectric ceramic wafer The bonding surfaces of the wafer 2 are bonded and fixed by insulating glue 3. The upper piezoelectric ceramic wafer 1 includes an upper support portion 11 and an upper left clamp finger 12 and a right upper clamp finger 13 integrally connected to the upper support portion 11. The finger portion 12 and the upper right pincer finger portion 13 are symmetrical along the center line of the upper support portion 11, and the free ends of the upper left pincer finger portion 12 and the free ends of the upper right pincer finger portion 13 are integrally provided with upper extensions that can be used to install different clamping heads. part 14, the lower piezoelectric ceramic wafer 2 includes ...

Embodiment 2

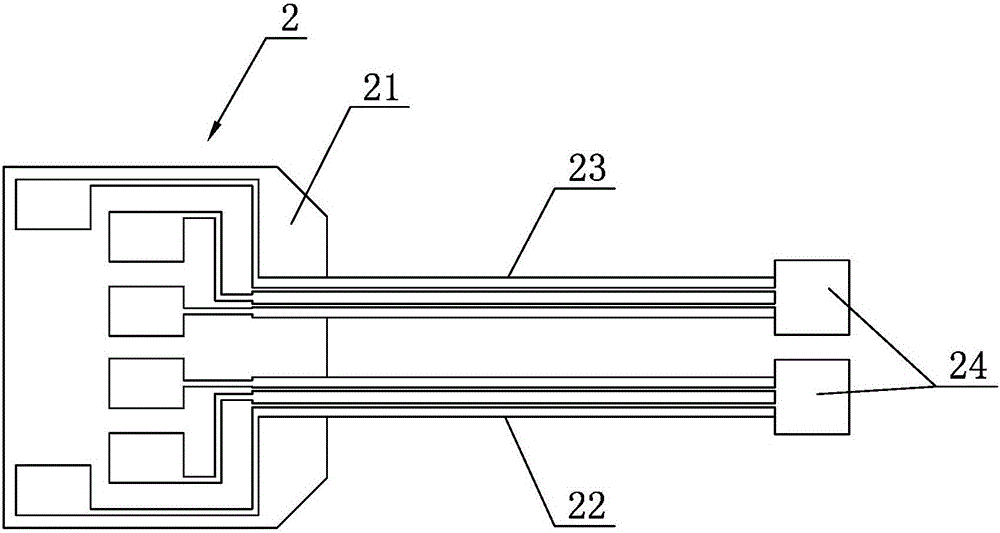

[0021] Embodiment 2: a kind of four-degree-of-freedom piezoelectric micro-clamp, comprising an upper piezoelectric ceramic wafer 1 and a lower piezoelectric ceramic wafer 2, the bonding surface of the upper piezoelectric ceramic wafer 1 and the lower piezoelectric ceramic wafer 2 The surfaces are bonded and fixed by insulating glue 3. The upper piezoelectric ceramic wafer 1 includes an upper support part 11 and an upper left clamp finger part 12 and a right upper clamp finger part 13 integrally connected to the upper support part 11. The pliers fingers 13 are symmetrical along the center line of the upper support 11, and the free ends of the upper left pliers fingers 12 and the free ends of the upper right pliers fingers 13 are respectively integrally provided with upper extensions 14 that can be used to install different clamping heads. The electric ceramic wafer 2 includes a lower support part 21 and a lower left clamp finger part 22 and a right lower clamp finger part 23 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com