Novel aluminum alloy plastic-absorbing mold

A blister mold and aluminum alloy technology, which is applied in the field of blister molding machine accessories, can solve the problems of increasing intermediate links and reducing the softening efficiency of plastic sheets, and achieves the effects of rapid temperature rise, improved softening efficiency, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

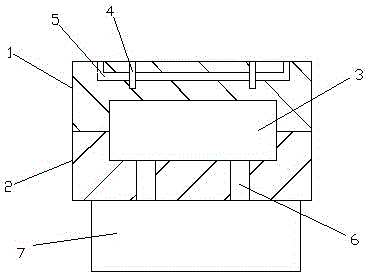

[0017] figure 1 It is a schematic diagram of the structure of a new aluminum alloy blister mold according to an embodiment of the present invention; the blister mold includes an upper mold 1 and a lower mold 2, and after mold closing, a blister cavity 3 is formed, and the upper mold 1 has a built-in air extraction channel 4 and Ring-shaped water-cooling structure 5, the lower mold 2 has a built-in warm air channel 6 structure, the lower mold 2 has an external warm air supply device 7, one end of the warm air channel 6 is a plastic cavity 3, and the other end is a Warm air supply device 6.

[0018] In the new-type aluminum alloy blister mold ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com