Plant oil-based polyurethane composite material and preparation method therefor

A vegetable oil-based, composite material technology, applied in the field of vegetable oil-based polyurethane composite materials and their preparation, can solve problems such as difficult operation, static electricity, air pollution, etc., and achieve the effects of stabilizing product performance, reducing air pollution, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

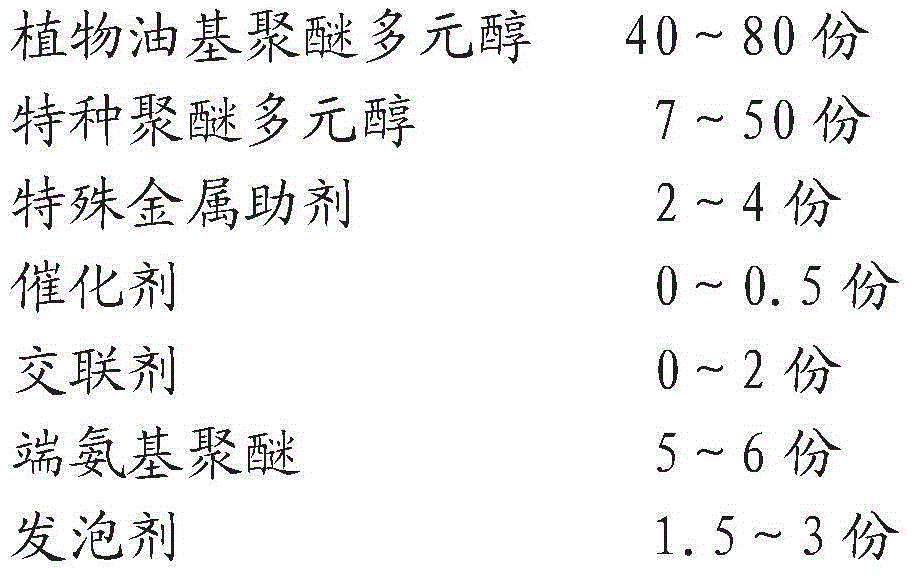

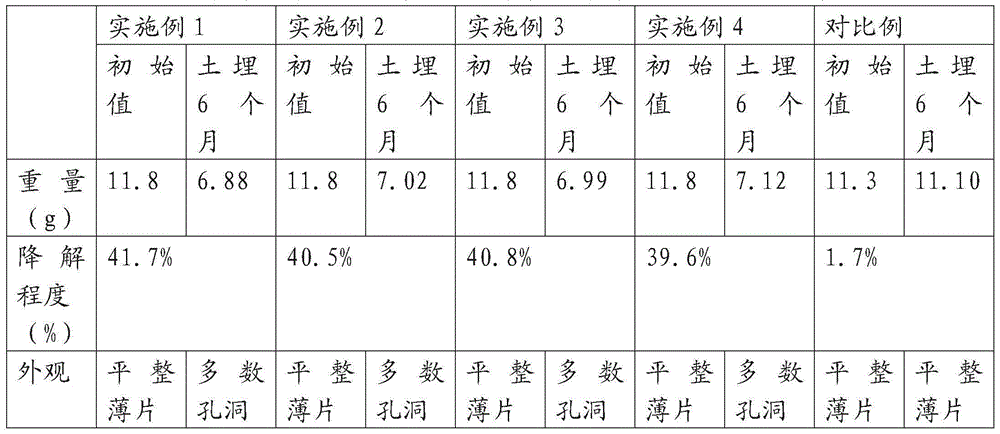

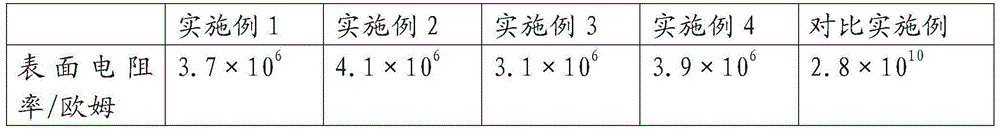

[0020] Weigh 40 parts by weight of castor oil-based polyether polyol, 30 parts by weight of special polyether polyol, 4 parts by weight of special metal additives, 0 parts by weight of catalyst, 2 parts by weight of crosslinking agent, 5 parts by weight of terminal amino Polyether and 1.5 parts by weight of foaming agent were stirred and mixed to obtain group A, and then 50 parts by weight of isocyanate of group A and group B were stirred and mixed, and reacted and formed at a temperature of 60°C.

[0021] Among them, castor oil-based polyether polyol has a functionality of 2.5 and a hydroxyl value of 120-140KOH / g; a special polyether polyol has a molecular weight of 4000-6000 and a functionality of 3 and a hydroxyl value of 34-42KOH / g; The agent is a silver ion additive; the amino-terminated polyether is the polyether amine of T-403 of Huntsman Company of the United States; the foaming agent is a mixture of water and fluorodichloroethane (HCFC-141B); the catalyst is Momentive ...

Embodiment 2

[0023] Weigh 80 parts by weight of castor oil-based polyether polyol, 7 parts by weight of special polyether polyol, 2 parts by weight of special metal additives, 0.5 parts by weight of catalyst, 2 parts by weight of crosslinking agent, 6 parts by weight of terminal amino Polyether and 3 parts by weight of foaming agent were stirred and mixed to obtain group A material, and then 30 parts by weight of isocyanate of group A and group B were stirred and mixed, and reacted and formed at a temperature of 40°C.

[0024] Among them, castor oil-based polyether polyol has a functionality of 2.5 and a hydroxyl value of 120-140KOH / g; a special polyether polyol has a molecular weight of 4000-6000 and a functionality of 3 and a hydroxyl value of 34-42KOH / g; The agent is a silver ion additive; the amino-terminated polyether is the polyetheramine of T-403 of Huntsman Company of the United States; the foaming agent is a fluorodichloroethane; the catalyst is the amine of NiaxA-33 or D-2000 of M...

Embodiment 3

[0026] Weigh 60 parts by weight of castor oil-based polyether polyol, 20 parts by weight of special polyether polyol, 4 parts by weight of special metal additives, 0 parts by weight of catalyst, 0 parts by weight of crosslinking agent, 5 parts by weight of terminal amino Polyether and 1.5 parts by weight of foaming agent were stirred and mixed to obtain group A material, and then 20 parts by weight of isocyanate of group A and group B were stirred and mixed, and reacted and formed at a temperature of 60°C.

[0027] Among them, castor oil-based polyether polyol has a functionality of 2.5 and a hydroxyl value of 120-140KOH / g; a special polyether polyol has a molecular weight of 4000-6000 and a functionality of 3 and a hydroxyl value of 34-42KOH / g; The agent is a silver ion additive; the amino-terminated polyether is the polyether amine of T-403 of Huntsman Company of the United States; the foaming agent is two mixtures of water and fluorodichloroethane; the catalyst is NiaxA-33 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com