Asphalt road and bridge antiskid maintenance material preparation method and applications of oil shale as filler

A technology of asphalt road and oil shale, which is applied in the application of oil shale as a filler and the preparation of asphalt road and bridge anti-skid maintenance materials. It can solve the problems of high cost of asphalt pavement and achieve the goal of improving other properties, smoothing the surface and increasing stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

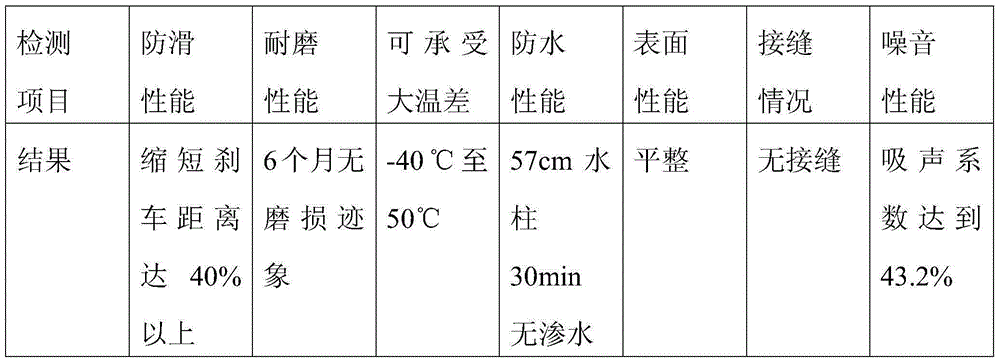

Examples

Embodiment 1

[0021] In step 1, the oil shale parent ore is crushed into fine particles by a pulverizer, and the diameter of the fine particles is 4 meshes, and solid particle fillers with a corresponding mesh number are obtained by screening.

[0022] In step 2, the above-mentioned fillers, additives and high-quality asphalt are in a ratio of parts by weight, filler: additive: high-quality asphalt=30:20:50, and the product is obtained after mixing at a temperature of 150 ° C; the product is in the form of "water-in-oil"; The additive is composed of 2 parts by weight of SBS, 2 parts by weight of EPS, 10 parts by weight of petroleum heavy liquid and 6 parts by weight of high-sulfur carbon.

[0023] In step 3, the above-mentioned product is used for patching the damaged road, or a layer of the above-mentioned product is re-paved on the damaged basic road surface as the coating of the road surface.

Embodiment 2

[0025] In the step 1, the oil shale is dry distillation oil shale waste residue. Other steps are the same as in Example 1.

Embodiment 3

[0027] In the step 1, the oil shale is small oil shale particles with a diameter of less than 6 mm that cannot be used in the dry distillation process. Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com