Air-flow/bubble spinning device

A technology of bubble spinning and airflow, which is applied in the field of spinning, can solve the problems of easy breakdown of air and threat to the life safety of laboratory personnel, and achieve the effect of shape control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

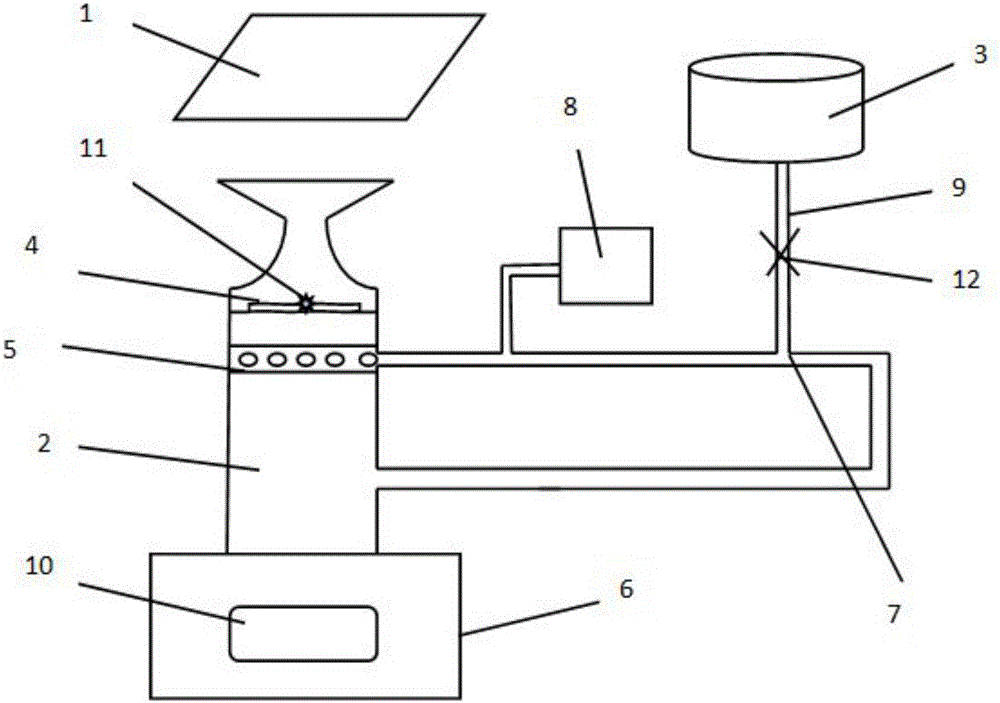

[0039] like figure 1 As shown, when the present invention is in use, the liquid storage device 3 is first filled with spinning solution, and the solution is injected into the bubble generator 5 through the connecting pipe 9, and the flow rate is controlled by the valve and the flow rate control device 12, and the nanoparticles are regulated. The nano particle content of ejection in the container 8, the airflow generator 6 transmits the airflow of suitable size in the airflow chamber 2 and the three-way pipe 7 through the airflow intensity control device 10, so that bubbles are generated in the holes of the bubble generator 5, and then the bubbles are Under the action of the air flow, when the air bubble explosion assisting device 4 whose temperature has been adjusted by the temperature or speed control device 11 is encountered, it explodes instantaneously, and the speed at which the broken bubble fragments are stretched in the thinning air flow cavity becomes larger, and finall...

Embodiment 2

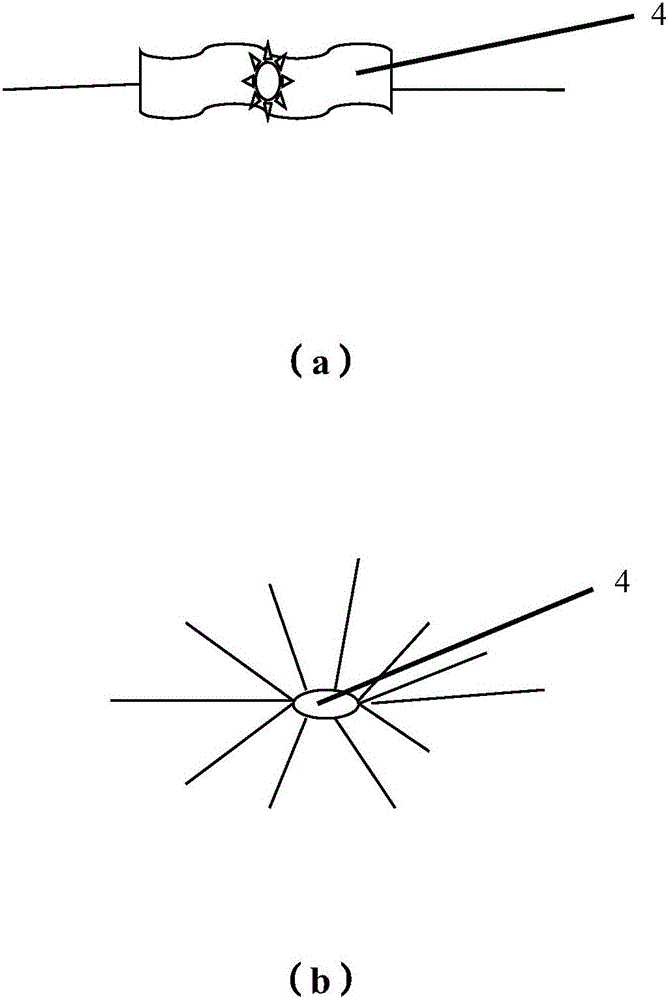

[0042] like figure 1 As shown, the installation steps of the air bubble air spinning device in use are consistent with those in Example 1. When the bubbles in the bubble generating device 5 are exploded, the bubble explosion assisting device is as follows: image 3 What is shown can be an electric heating component, regulated by the temperature or speed control device 11 ; it can also be a rotating fine needle component, regulated by the temperature or speed control device 11 .

[0043] In summary, compared with the prior art, the beneficial effects of the present invention include:

[0044] 1. When the bubble meets the bubble blasting booster device, it explodes instantly and is stretched in the high-speed airflow field, which makes the prepared nanofibers thinner in diameter and higher in yield, and there is no electrostatic process. The whole device is safe and easy to control; at the same time, through the nanofiber Nanoparticles are added to the airflow cavity in the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com