Pressure trigger type underwater cast-in-place pile elevation locating device and using method thereof

A technology of underwater perfusion and positioning device, which is applied in the test of infrastructure, construction, infrastructure engineering and other directions, can solve the problems that the alarm accuracy cannot be guaranteed, there is no waterproof protection device, and the internal circuit is short-circuited. The effect of less quantity and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

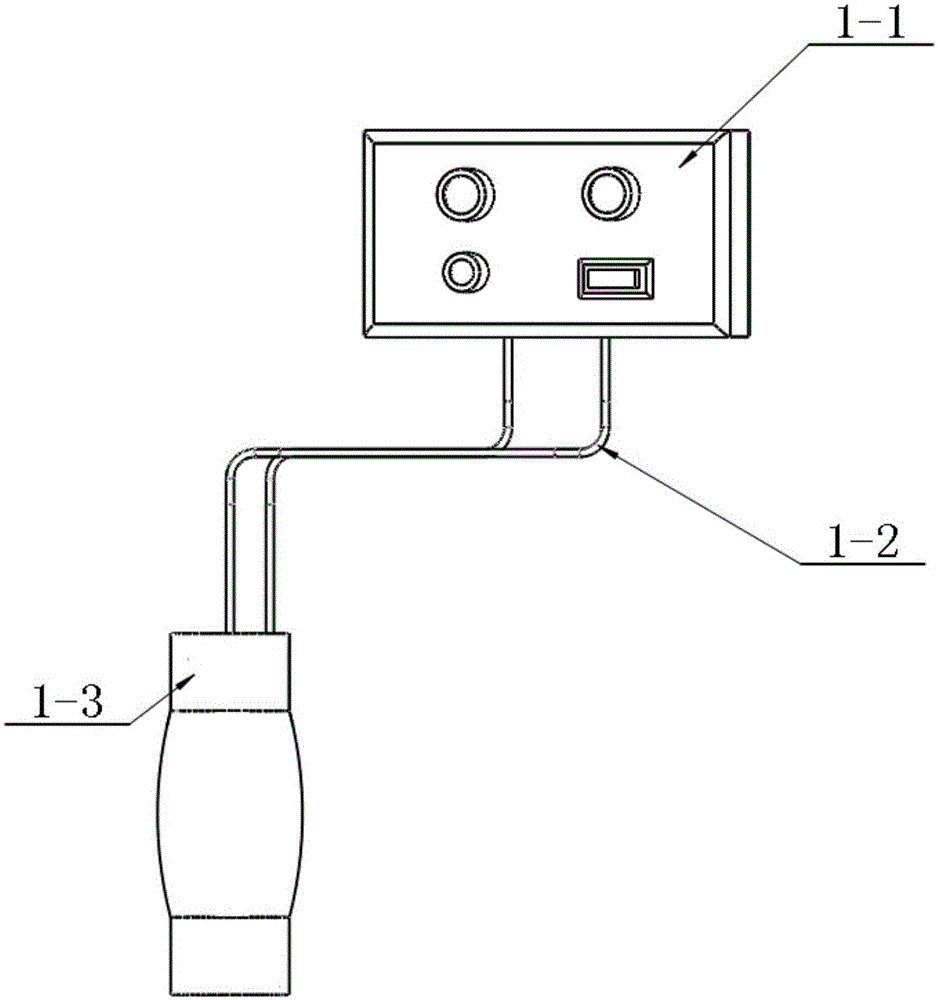

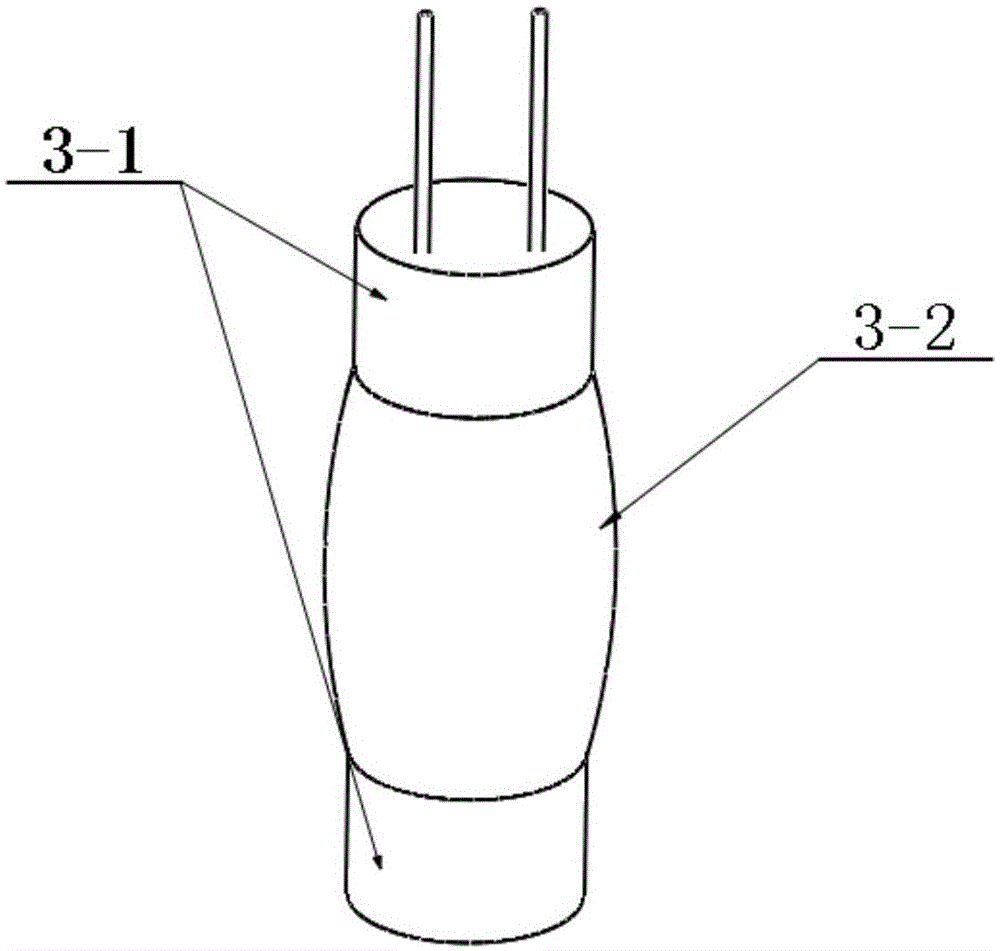

[0047] Such as Figure 1-Figure 5 As shown, a pressure-triggered underwater pile filling control device includes a hand-held buzzer and vibration alarm 1-1, a waterproof wire 1-2, and an underwater pressure probe 1-3. Wherein, the positive and negative pole inlets at the bottom of the hand-held alarm are respectively connected to one end of the two wires, and the other end of the wire is connected to the underwater pressure probe 1-3, and waterproof treatment is done.

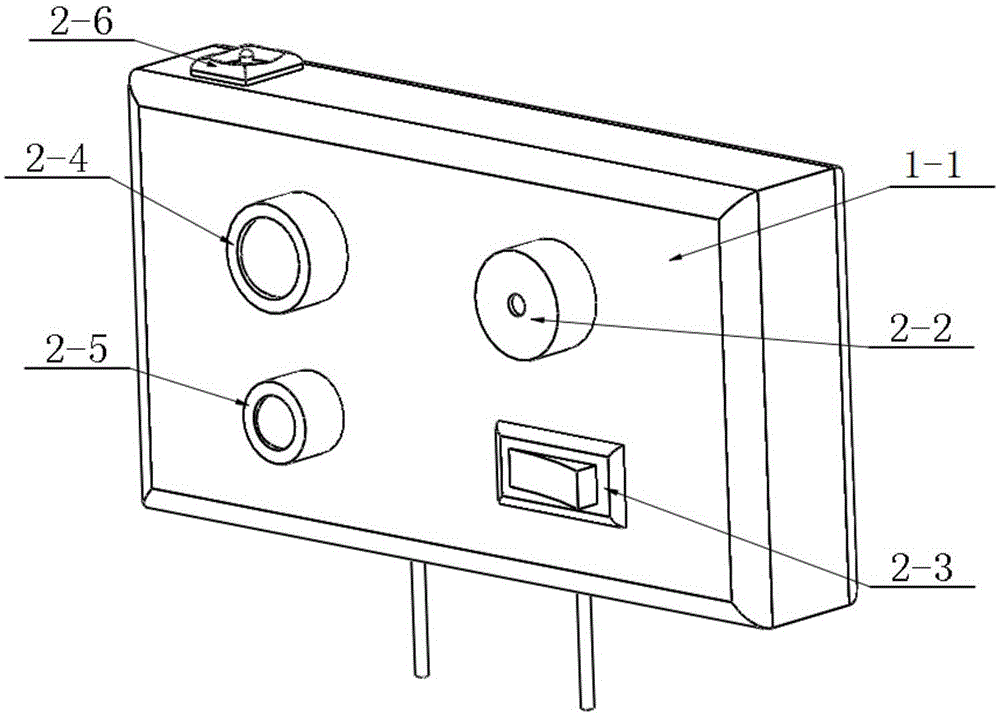

[0048]The hand-held buzzer and vibration alarm 1-1 is equipped with a working indicator light 2-4, a charging indicator light 2-5, a buzzer 2-2, a power switch 2-3, a built-in lithium battery and a built-in vibrator, There are charger connector sockets 2-6 on the top surface, and positive and negative pole inlets on the bottom surface, which can be connected with waterproof wires 1-2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com