Multifunctional handle operating control system for loader

A control system and multi-functional technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of increased labor intensity of operators, single function of joystick, and increased difficulty of operation, so as to improve operating efficiency and control The effect of simplicity and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

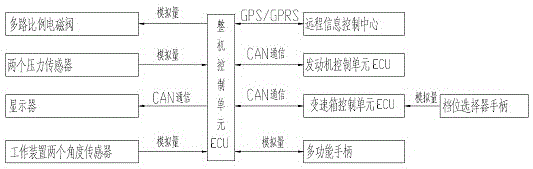

[0026] like figure 1 As shown, the present invention includes a complete machine control unit, and a remote information control center, an engine control unit, a gearbox control unit, a multifunctional handle, a multi-way proportional solenoid valve, a display, and a device installed on the working device. Two pressure sensors and two angle sensors, and a gear selector handle connected to the transmission control unit. The two pressure sensors are respectively installed at the oil inlet and the oil outlet of the hydraulic oil cylinder of the working device.

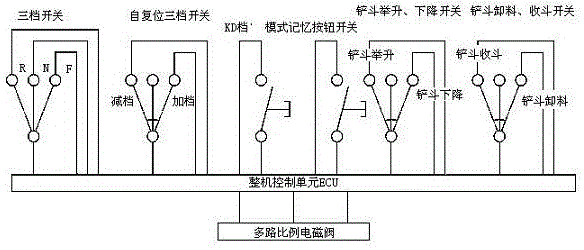

[0027] like figure 2 As shown, the multifunctional handle integrates a three-speed switch with direction gear function, a self-resetting three-speed switch with plus and minus gear function, a KD button with KD gear function, a mode memory button, and bucket lifting and lowering functions. The three-speed swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com