Accident safety method and system for water supply

A technology for water supply systems and accidents, which is applied in the field of accident-safe water supply methods and water supply systems, can solve problems such as wasting electric energy, freezing of water tanks, and potential safety hazards, and achieve the goal of not increasing the load of the plant, preventing water quality from deteriorating, and solving the problem of antifreeze Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

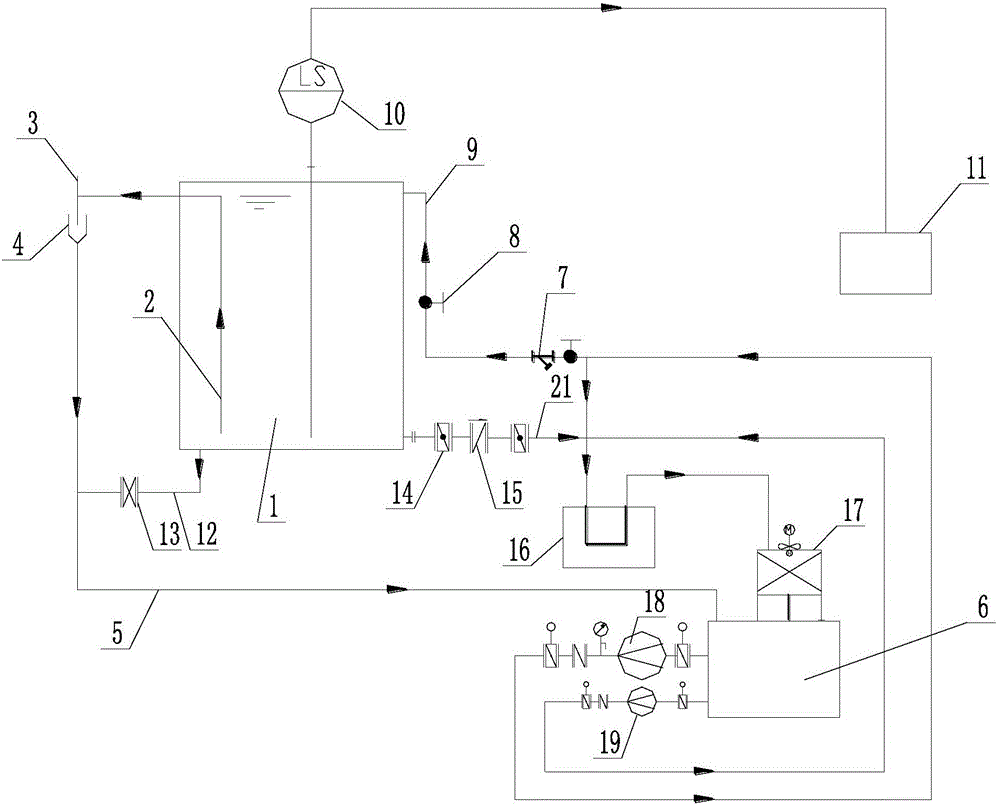

[0022] See figure 1 , is the flow chart of method of the present invention, and a kind of accident safe water supply method of the present invention comprises the steps:

[0023] 1) The circulating cooling water supply pump 18 draws cooling water from the suction well 6 of the circulating pump station, and sends the water to the water inlet pipe of the equipment 16 under pressure. production water loop;

[0024] 2) When the circulating cooling water supply pump 18 fails or the power is cut off, the accident diesel engine water supply pump 19 starts automatically, and the accident water tank 1 supplies water to the equipment 16 through the outlet pipe 21 before the accident diesel engine water supply pump 19 reaches the normal working state;

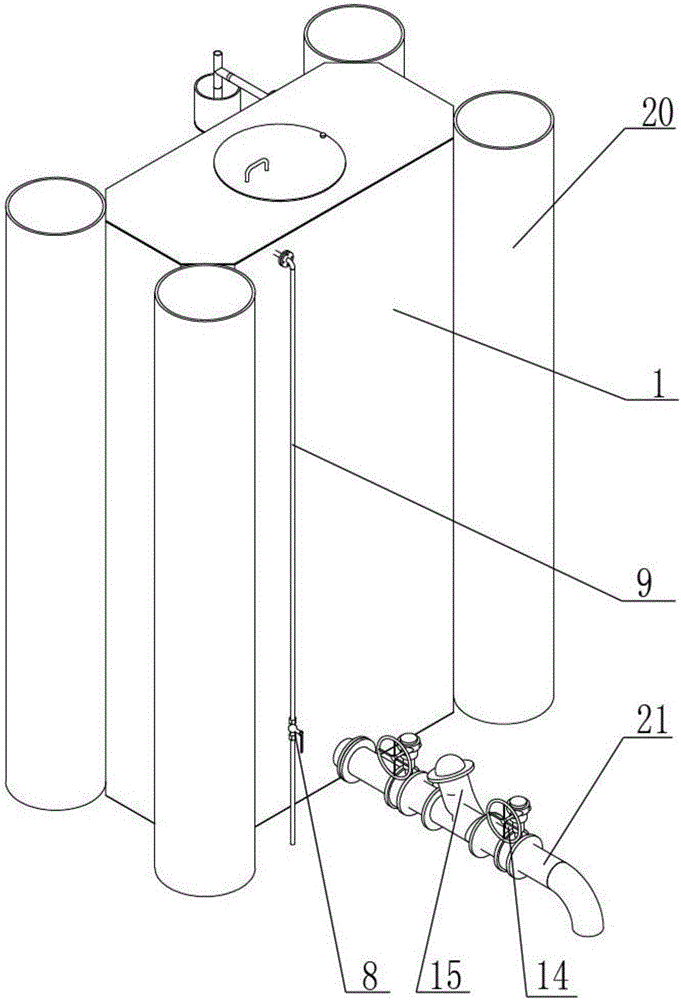

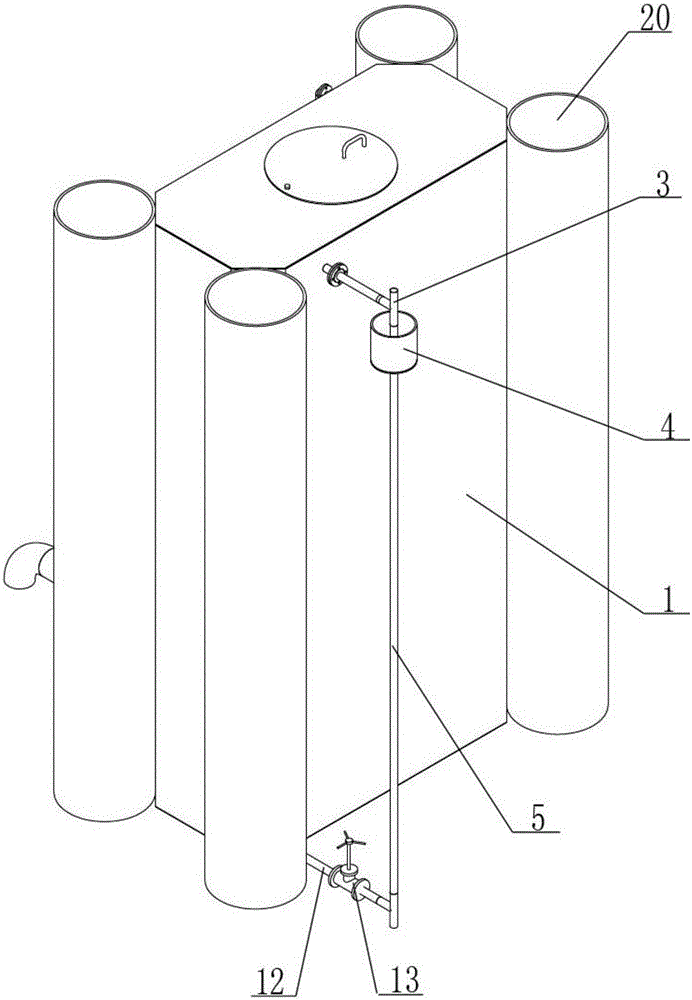

[0025] 3) The accident water tank 1 arranged in the space of the factory building column 20 forms a safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com