A temperature adjustment system for controlling the temperature of transmission oil through cooling medium

A transmission oil and cooling medium technology, applied in the direction of gear lubrication/cooling, components with teeth, transmission parts, etc., can solve the problems of increased emissions, large fluctuations in transmission oil temperature, waste of cooling performance, etc., to achieve accurate Control, accurate transmission oil temperature, the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

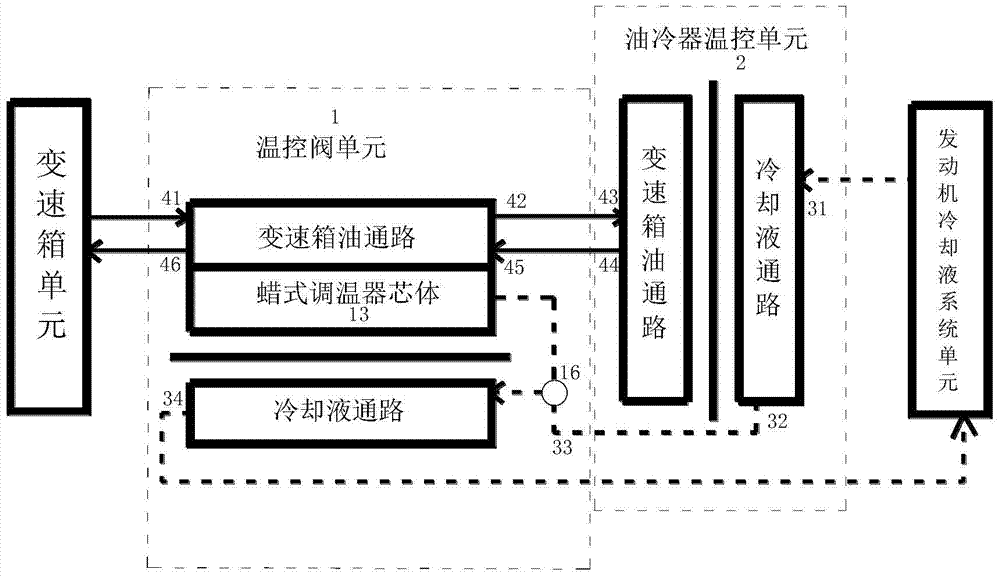

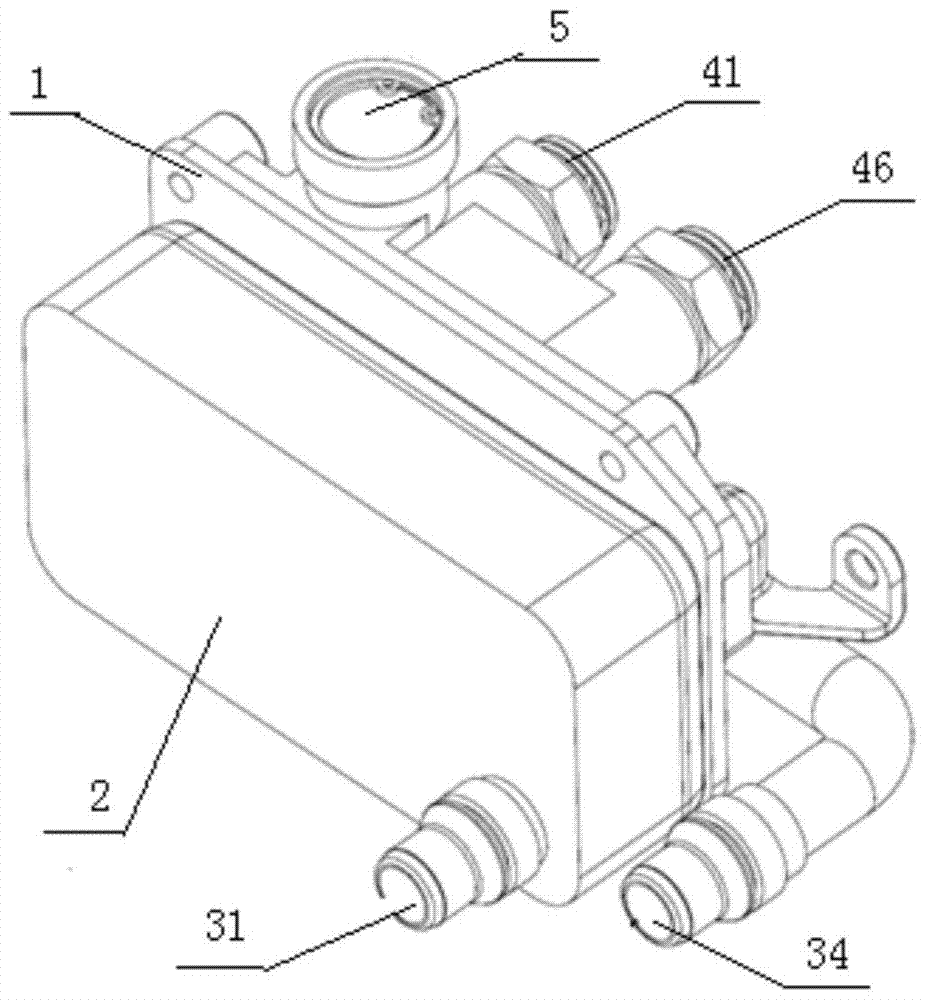

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

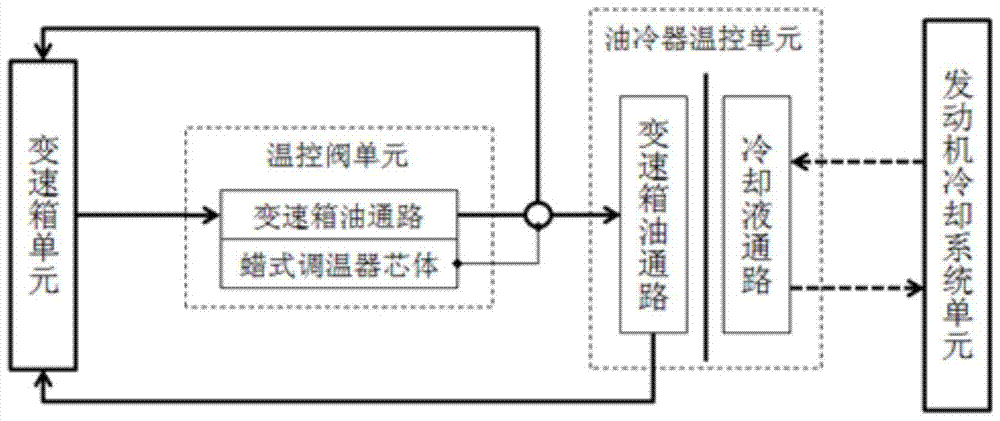

[0025] Such as figure 1 As shown, the temperature control principle of the traditional gearbox temperature adjustment system is:

[0026] When the transmission oil is low temperature: the transmission oil flows in from the oil inlet of the temperature control valve body and flows out from the oil outlet. The valve body flows to the oil outlet, forming a small circulation. During this process, the coolant in the engine cooling system has been flowing in the oil cooler, and no heat exchange occurs at this time.

[0027] When the transmission oil rises to the set temperature: the core of the wax-type thermostat feels the high oil temperature, the valve opens, and the transmission oil flows into the oil cooler control unit, forming a large cycle. At this time, the transmission oil and the cooling fluid exchange heat in the oil cooler control unit to reduce the oil tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com