Device used for automatically measuring and compensating for water level

A water level measurement and automatic technology, applied in the control of water supply, lighting and heating equipment, preheating, etc., can solve the problems of reducing labor intensity, inability to accurately measure, inability to accurately measure the internal water level, etc., to achieve the continuity of work and The effect of improving safety and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

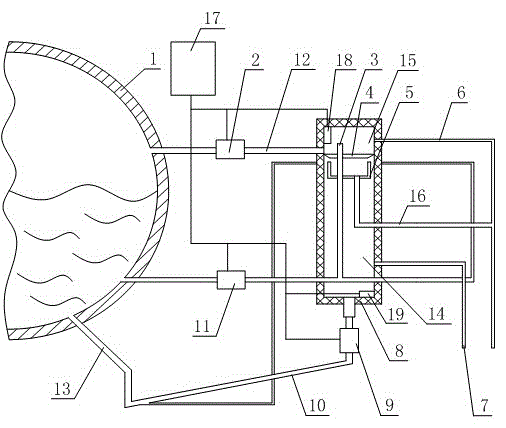

[0012] Such as figure 1 As shown, a device for automatic water level measurement and compensation includes a hollow and sealed drum 1, and a dual-chamber balance container is arranged outside the drum 1, and the dual-chamber balance container includes a hollow and sealed shell 8 inside. , the housing 8 is provided with an isolation plate 4, and the side wall of the isolation plate 4 is seamlessly connected with the side wall of the housing 8, the housing 8 is provided with a connector 3, and the top of the connector 3 passes through the isolation plate 4 It is arranged above the isolation plate 4; the drum 1 is connected with a downcomer 13, one end of the downcomer 13 communicates with the inside of the drum 1, and the other end passes through the shell 8 and communicates with the bottom end of the connector 3 and then communicates with the pot The cylinder 1 is connected internally, the downcomer 13 is provided with a control valve 11, the control valve 11 is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com