Electromagnetic heating boiler system

A technology for heating boilers and electromagnetic heating coils, applied in the field of industrial furnaces, can solve the problems of inability to realize the recycling use of organic heat carriers, unreasonable structural design of industrial heating furnaces, inability to meet the needs of workshop operations, etc., and achieves improved energy utilization and automation. The effect of high degree and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

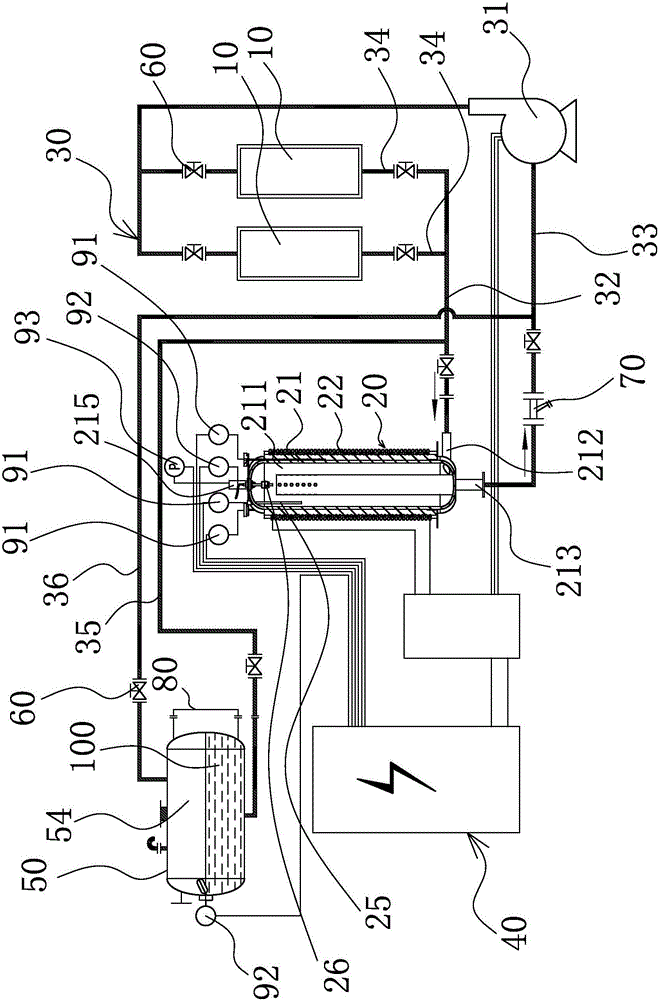

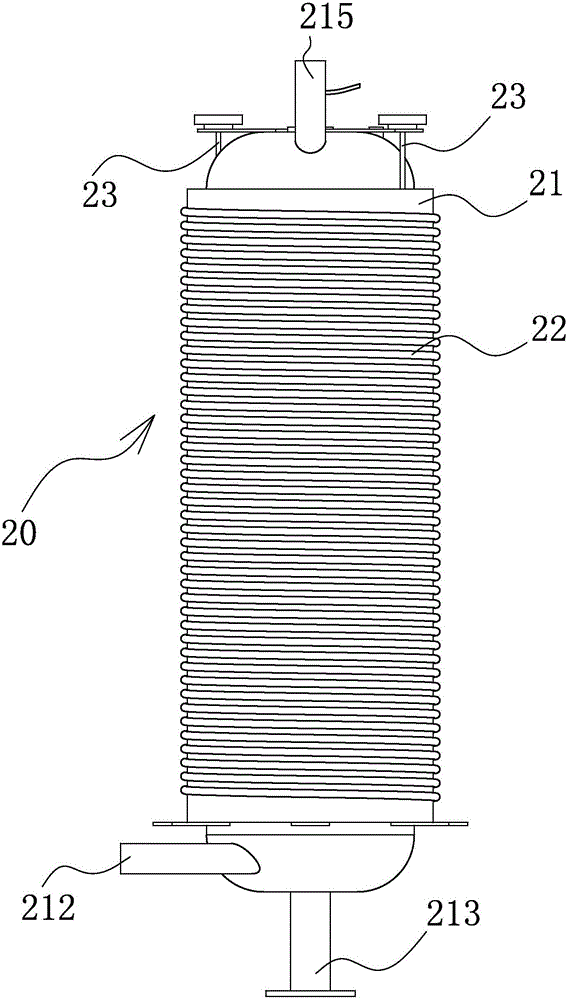

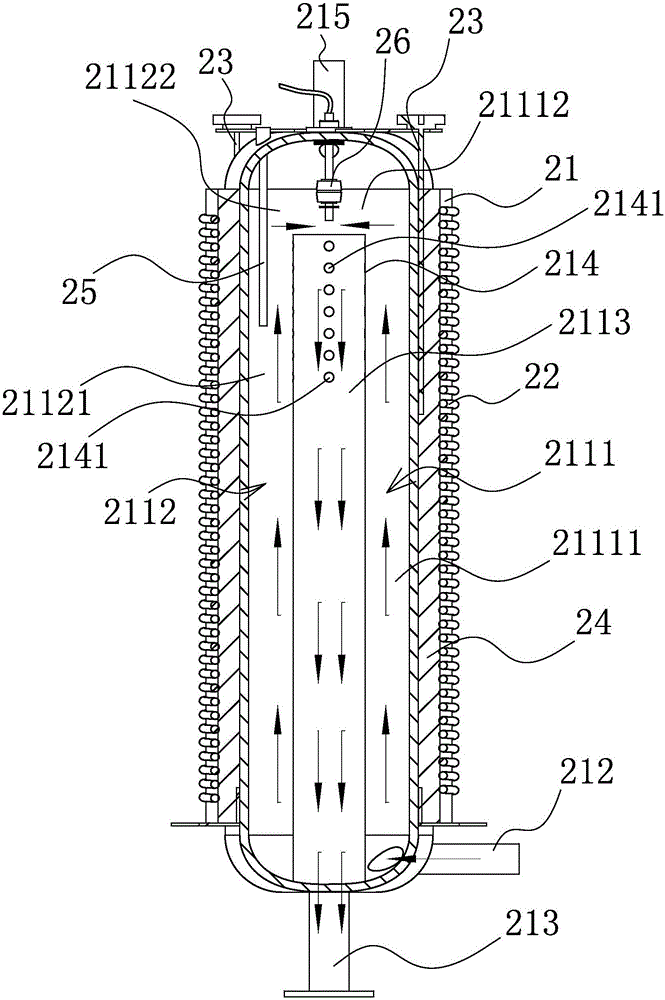

[0030] The invention protects an electromagnetic heating boiler system, which has a heating furnace 20 (heating boiler) and a circulation mechanism 30 for circulating an organic heat carrier, so as to facilitate the regeneration and utilization of resources.

[0031] This electromagnetic heating boiler system uses electromagnetic heating to heat organic heat carriers such as heat conduction oil 100, and transmits the heat energy generated after heating to heat-using equipment 10, wherein the heating furnace 20 is a low-pressure (normal pressure or lower A special industrial furnace that can provide high temperature heat energy under pressure).

[0032] The existing industrial heating furnace 20 using organic heat carrier f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com