Lotus flower type condenser and hertz dry cooling system

A condenser, lotus technology, applied in the field of lotus condenser and hertz dry cooling system, can solve the problems that have not entered the stage of practical application, etc., achieve simple operation and maintenance, low condenser pressure, novelty The effect of structure and finesse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

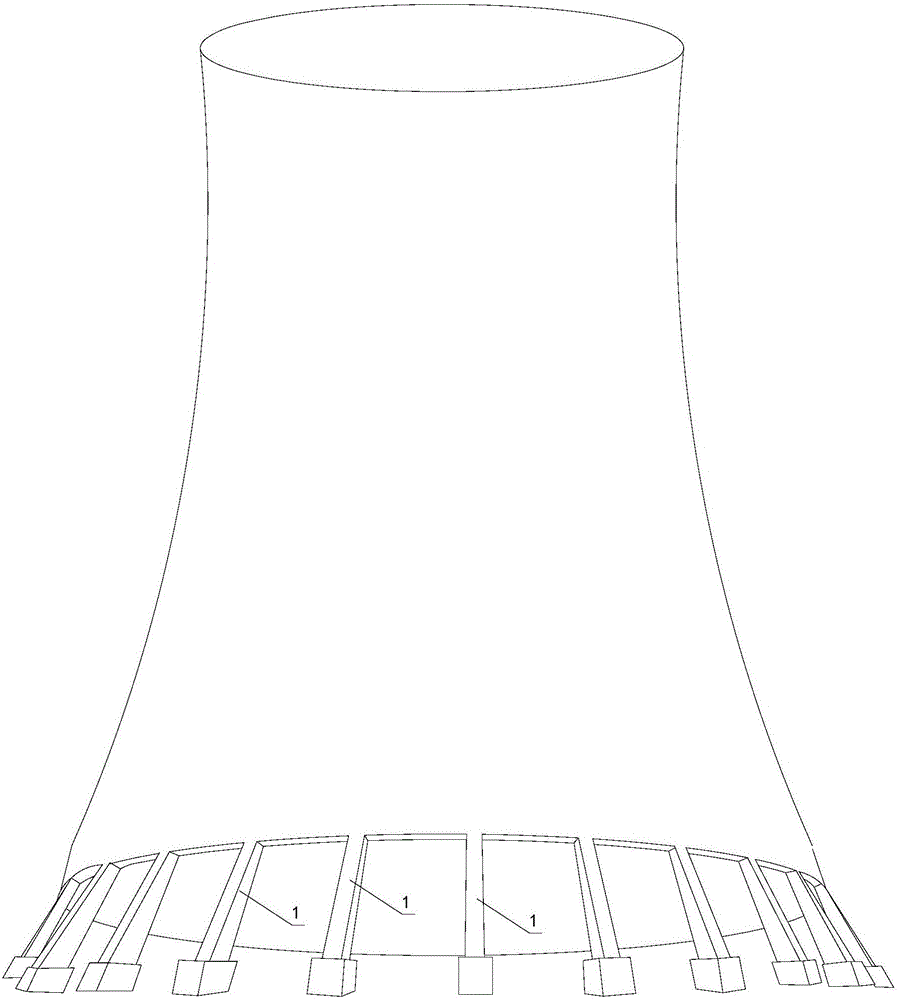

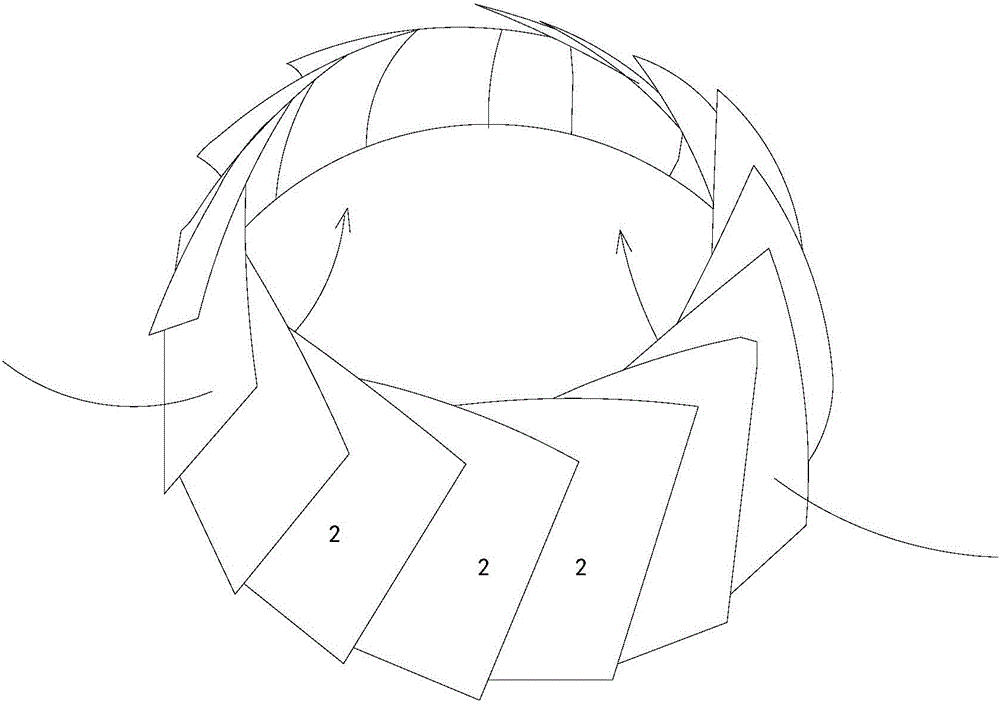

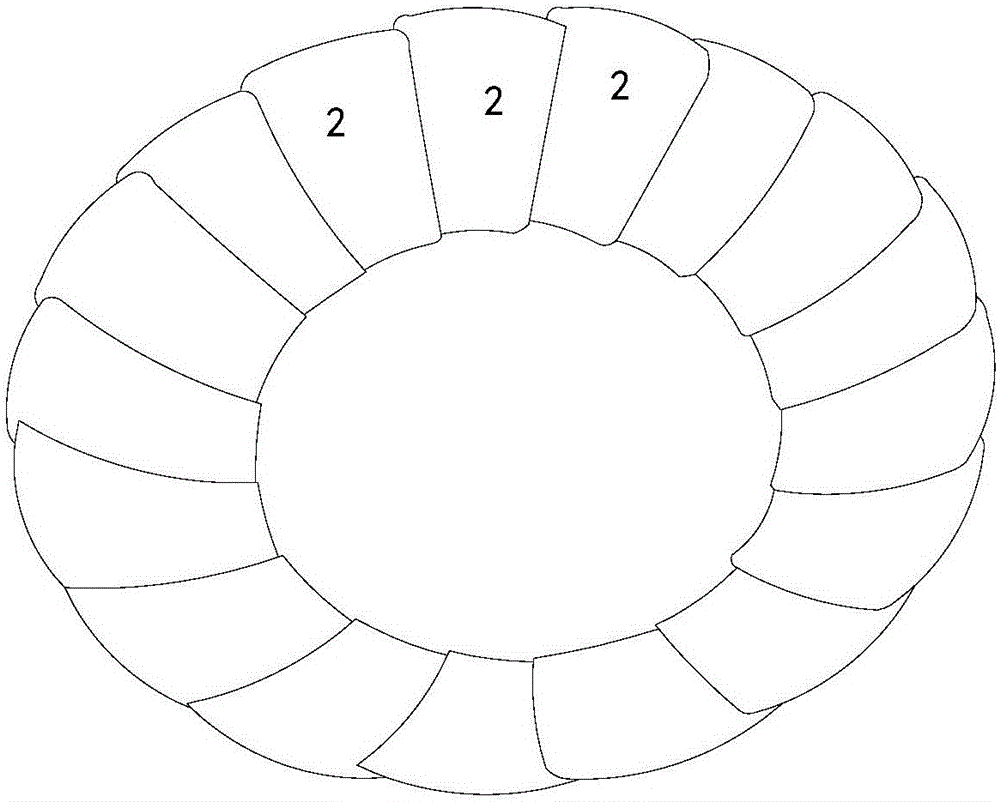

[0048] see Figure 1 to Figure 10 As shown, a lotus condenser of the present invention is a direct air-cooled condenser, which includes two steam distribution risers 4 and a condensed water return riser 6 between the two steam distribution risers 4; The steam riser 4 and the condensate return riser 6 are connected by a plurality of inclined flat base pipes 5 to form a finned tube sheet 2; the upper part of the steam distribution riser 4 has a forward and reverse flow partition slant plate 8 to form a forward flow The flow tube bundle and the reverse flow tube bundle; the lower part of the steam distribution riser 4 is connected to the horizontal pipeline through an equal diameter elbow, and a rotatable movable joint 3 is set on the horizontal pipeline, and a ball bearing 20 is set to support the entire tube sheet. A pumping pipe 7 is provided at the top of the steam distribution standpipe for taking out gas and non-condensed gas during initial vacuuming and operation. The suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com