A solid wood composite floor color detection device

A solid wood composite flooring and detection device technology, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of high cost, expensive equipment, difficult operation, single and fixed angle of product and sample placement, etc., so as to reduce labor intensity, ideal use prospect, The effect of shortening the running distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

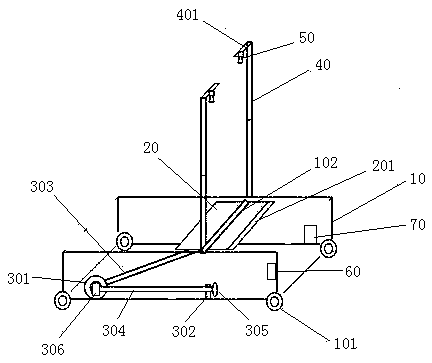

[0024] The invention provides a solid wood composite floor color matching detection device, which includes:

[0025] The underframe 10, wherein the underframe is cubic, and universal wheels 101 are provided at the bottom of the underframe 10; the longitudinal straight rods of the underframe are of a telescopic structure; a rotating shaft 102 is provided on both sides of the upper frame of the underframe;

[0026] The observation stand 20 is set on the rotating shaft 102 and connected to the rotating shaft 102. It is rectangular. The observation stand 20 rotates vertically around the axis. The surface of the observation stand 20 is made of special PVC material and the color is medium gray. The baffle 201 is used to fix the template;

[0027] The turbine drive train is arranged in the base frame 10 and consists of a roller 301, a base 302, an oblique rod 303, a worm 304 and a hand wheel 305. The roller 301 and the base 302 are arranged on the base frame 10, and the center of the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com