Silicone rubber insulating material hydrophobicityhydrophobicity transfertestingmethod

A hydrophobic migration, silicone rubber insulation technology, applied in analytical materials, measuring devices, instruments, etc., can solve problems affecting the normal operation of the power grid, high safety risks of insulators, etc., to reduce workload and safety risks, and achieve good consistency , the effect of simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

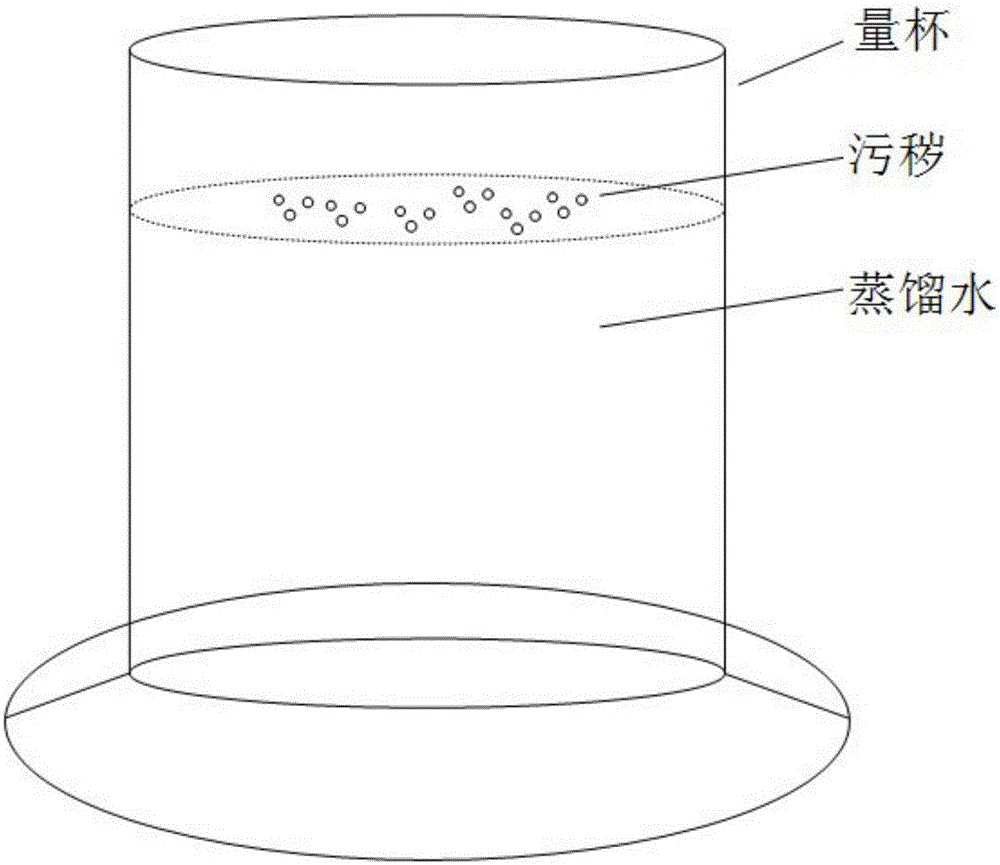

[0019] A method for testing the hydrophobic mobility of silicone rubber insulating materials, such as figure 1 shown, including the following steps:

[0020] Step 1. Obtain contamination on site that can accurately represent the state of the insulator surface.

[0021] Choose sunny weather and air humidity not greater than 60%, use a brush to pick up the dirty surface of the operating insulator, put it in an airtight container (such as a plastic bag), and characterize the state of the insulator surface.

[0022] Step 2. Pre-treat the insulator surface contamination obtained on site in the laboratory to remove larger particles such as gravel in the contamination, and weigh 10g for use. The laboratory maintains a room temperature of 25°C and a relative humidity of 40%.

[0023] Step 3. Pour 500ml of distilled water into a measuring cup with a diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com